Electronic chip packaging structure and method

A packaging method and technology for electronic chips, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of offsetting the efficiency of substrate assembling, low efficiency, and time-consuming injection molding, achieving good dimensional stability, cost reduction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

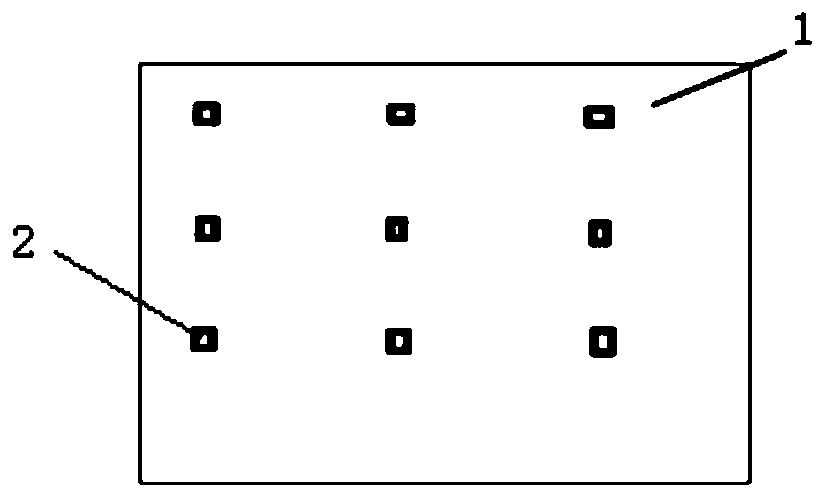

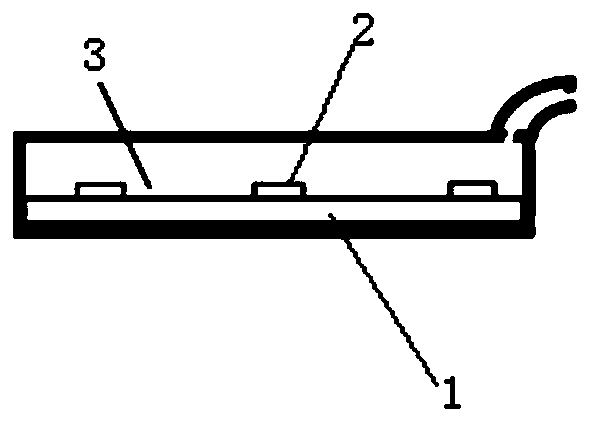

Image

Examples

specific Embodiment 2

[0063] The implementation steps of specific embodiment 2 are as follows:

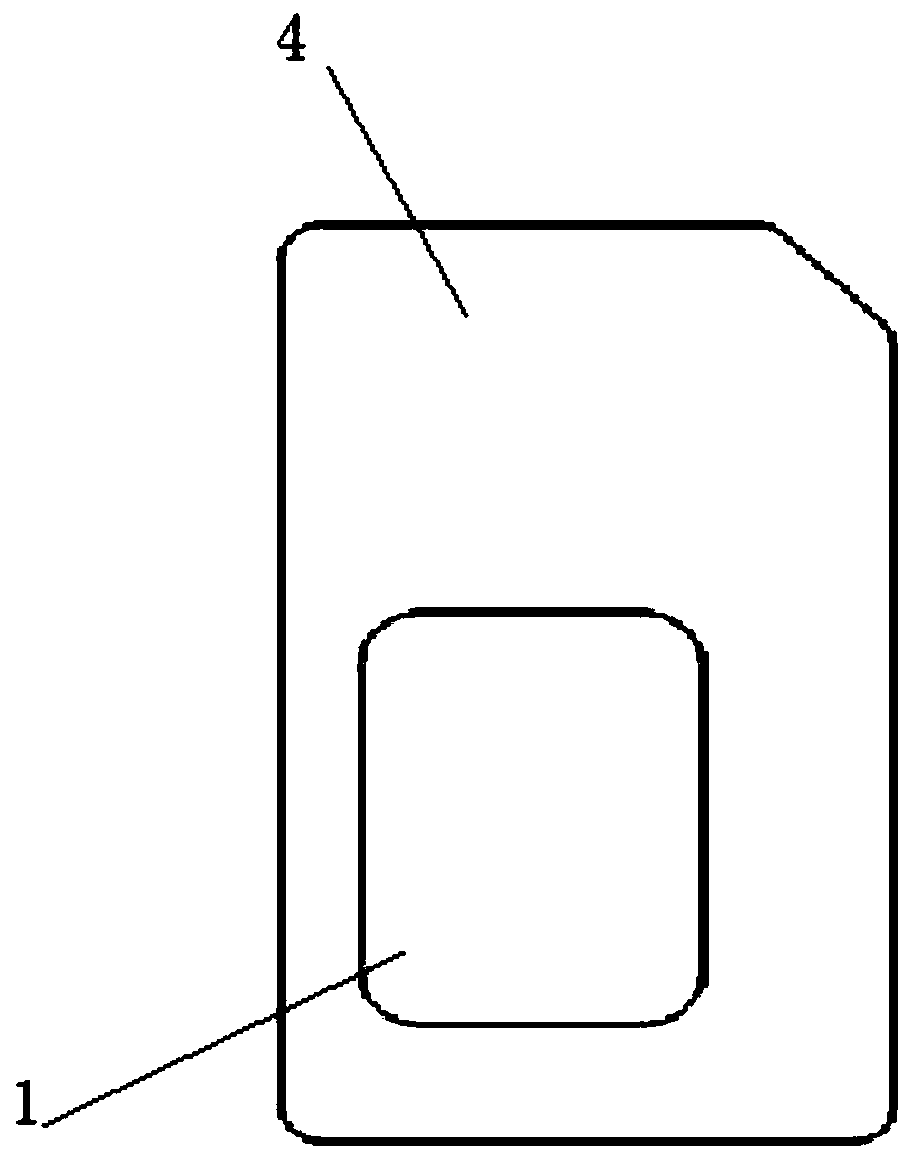

[0064] 1. Choose an aluminum alloy plate with a thickness of about 0.8mm, a low coefficient of thermal expansion, and high hardness --- aviation aluminum sheet as the finished product carrier 4.

[0065] 2. CNC processing of aviation aluminum sheet. Mill groove 5 on one of the planes of the aviation aluminum sheet, and cut around the plane. Obtain the semi-finished product of the Internet of Things card carrier as shown in the figure, the size of the groove 5 and the substrate 1 have no clear size difference, which depends on the difference in thermal expansion coefficient between the various components and the tolerance formed in production. The groove 5 is a stepped groove. Since the chip 2 protrudes from the plane of the substrate 1, a stepped groove is provided to provide a mounting space for the chip 2 on the finished carrier 4. The first-level groove of the stepped groove is a rectangular struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com