Preparation method of recycled asphalt mixture

A technology of recycled asphalt and mixture, which is applied in the direction of sustainable waste treatment, solid waste management, and climate sustainability. Improved performance, anti-rutting performance, and high-temperature stability, and reduced regeneration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

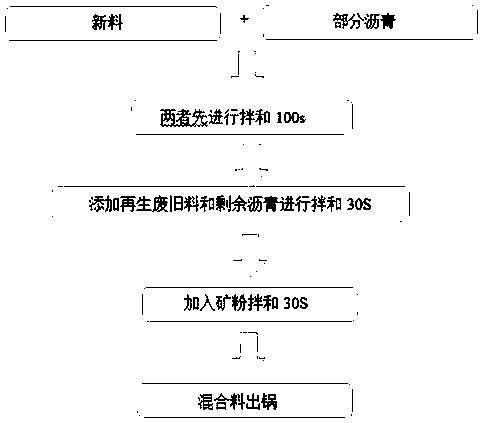

Method used

Image

Examples

Embodiment 1

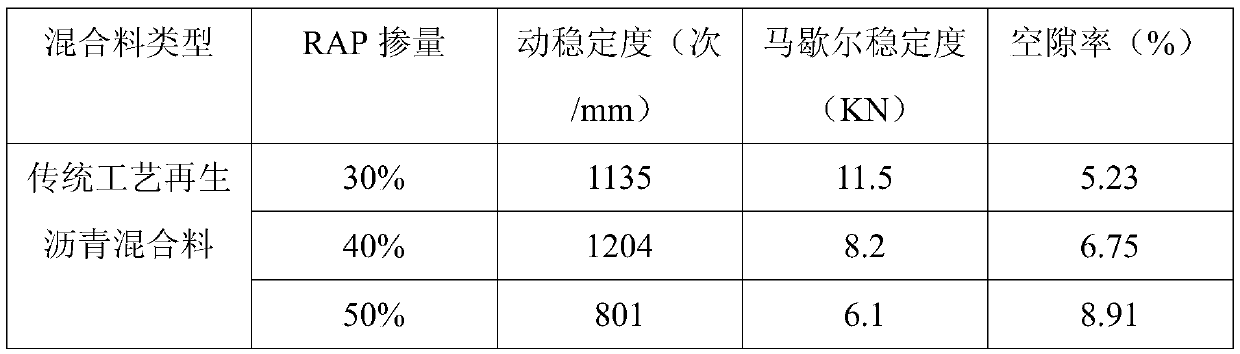

[0038] Samples of recycled asphalt mixtures with different dosages (30%, 40%, 50%) were prepared by the traditional method and the method of the present invention for comparative research.

[0039] AC~20 type recycled asphalt mixture (30% RAP) synthetic mineral composition and mass ratio: 65 parts of new aggregate, including 21 parts of 0-3mm machine sand, 12 parts of 3-5mm crushed stone, 5-10mm 15 parts of gravel, 10 parts of 10-17mm gravel, 7 parts of 17-26.5mm gravel; 30 parts of recycled asphalt mixture, including 12 parts of 0-5mm material, 6 parts of 5-10mm material, 12 parts of 10-17mm material , After the extraction test, the oil content of 0-5mm material is 5wt%, the oil content of 5-10mm material is 3.8wt%, and the oil content of 10-17mm material is 3.5wt%; 5 parts of mineral powder; 4.82 parts of total asphalt , minus 1.248 parts of oil content in the recycled asphalt mixture, the required amount of new asphalt (A70-A base asphalt) is 3.572 parts;

[0040] AC~20 ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com