Unsealing method for silver wire plastic package device

A silver wire and device technology, applied in the field of unsealing electronic components, can solve the problems of strong corrosion of silver wire, low corrosion of silver wire, damage of silver wire, etc., so as to ensure the stability of unsealing and prevent the corrosion of silver wire. , Stabilize the effect of silver wire being corroded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Unpacking of plastic packaging materials that are easily corroded by fuming nitric acid

[0047] 1.1 Test the influence of the choice of unsealing solution on the silver wire.

[0048] The specific composition of the unsealing solution and the use temperature of the unsealing solution are shown in Table 1 below.

[0049] The formula composition of each test example in the embodiment 1 of table 1

[0050]

[0051]

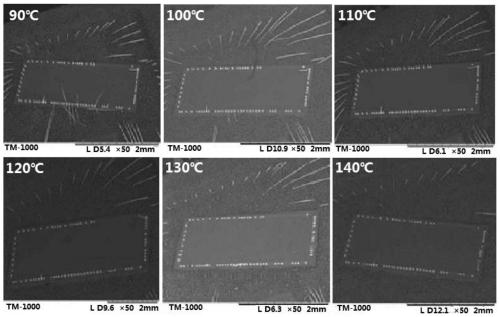

[0052] For the unpacking of the silver bonding wire whose plastic sealing material is EMC-9200 plastic sealing material and the diameter of the silver bonding wire is 20.2μm:

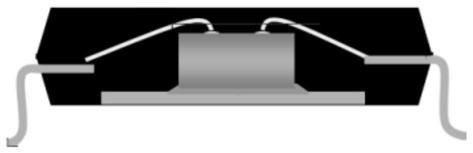

[0053] First use laser unsealing to remove part of the plastic packaging material to expose the arc of the silver wire (such as figure 1 shown), and then respectively use the unsealing solution in Table 1 to act on the plastic sealing material to unseal the silver wire, and the unsealed effects are respectively as follows Figure 1-3 and Table 2-3.

[0054] in, Figure 2-4 I...

Embodiment 2

[0073] For plastic sealing materials that are difficult to be corroded by fuming nitric acid

[0074] 2.1 Test the influence of the choice of unsealing solution on the silver wire.

[0075] Formulation and unpacked form of each test example in table 5 embodiment 2

[0076]

[0077]

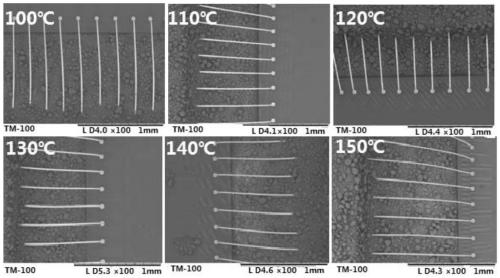

[0078] For the unpacking of the silver bonding wire whose plastic sealing material is G1250 plastic sealing material and the diameter of the silver bonding wire is 16.8μm:

[0079] First use laser unsealing to remove part of the plastic packaging material to expose the arc of the silver wire, and then use the unsealing solution in Table 5 to unseal the silver welding wire respectively. The unsealing effects are as follows: Figure 4-7 And shown in Table 5.

[0080] in, Figure 6-9 Followed by the mixture of fuming nitric acid+silver nitrate (solid state) as unsealing liquid, mixed acid (fuming nitric acid: oleum=5:1)+silver nitrate (solid state) as unsealing liquid, mixed acid (fuming nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com