Preparation method of carbon nanotube through-type growth MOF composite electrode material

A technology of carbon nanotubes and composite electrodes, which is applied in the direction of carbon nanotubes, nanocarbons, battery electrodes, etc., can solve problems such as the inability to effectively alleviate the collapse of the structure of MOF derivatives, and achieve improved rate performance and cycle performance, high active sites point, the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

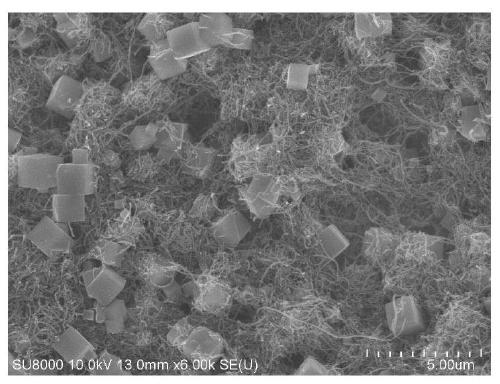

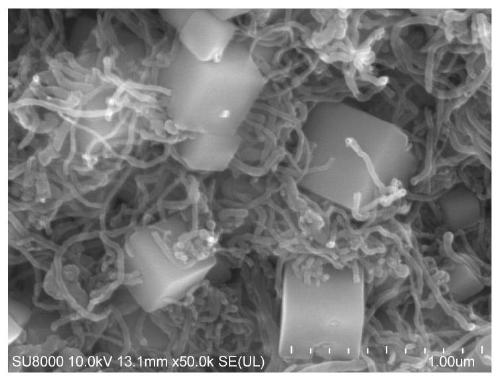

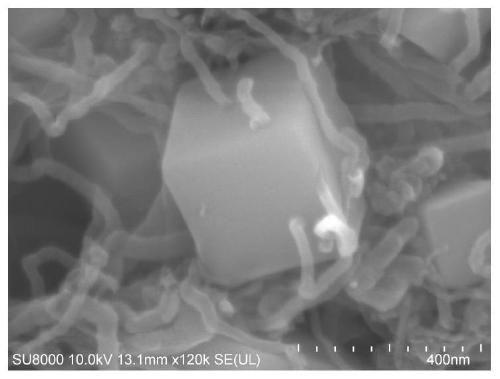

[0027] A method for preparing a carbon nanotube penetrating growth MOF composite electrode material, comprising the following steps:

[0028] (1) Sonicate 40 mg of carbon nanotubes in an aqueous solution until uniformly dispersed.

[0029] (2) Dissolve 1.2mmol sodium acetate tetrahydrate and 1.8mmol sodium citrate in 20ml of water to form solution A; dissolve 0.8mmol potassium cobaltcyanide in 20ml of water to form solution B; quickly dissolve A and pour it into solution B Form and stir for 1 min to form a precursor solution of Co-Co-PBA.

[0030] (3) Uniformly mix the carbon nanotube solution in step (1) with the Co-Co-PBA precursor solution in step (2), and then put it into ultrasonication for 1-12 hours.

[0031] (4) After ultrasonication, the mixed solution was centrifugally cleaned, and then vacuum-dried at 60°C.

[0032] (5) Heat-treat the Co-Co-PBA with carbon nanotubes through-grown in different atmospheres according to requirements: generate Co3O4@CNT composites at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com