New energy automobile part screening device

A new energy vehicle and screening device technology, applied in sorting and other directions, can solve problems such as time-consuming and laborious, low degree of automation, and hollow parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

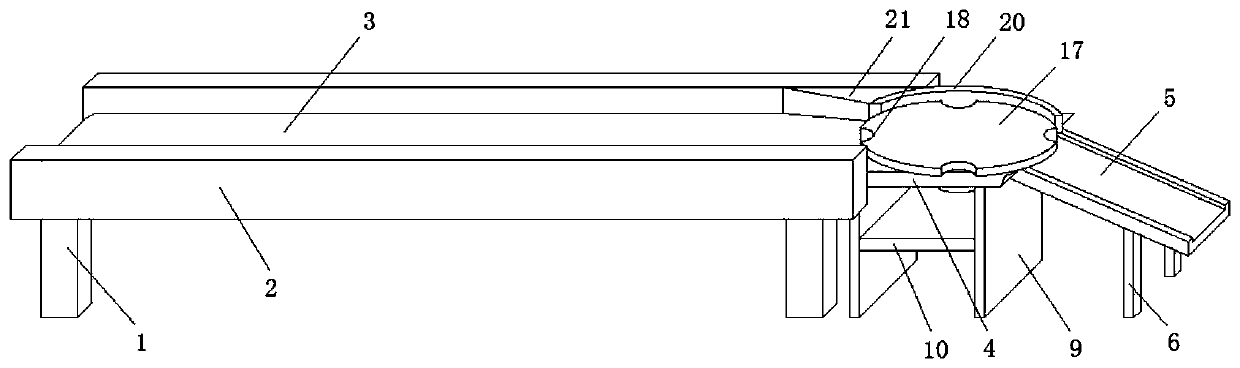

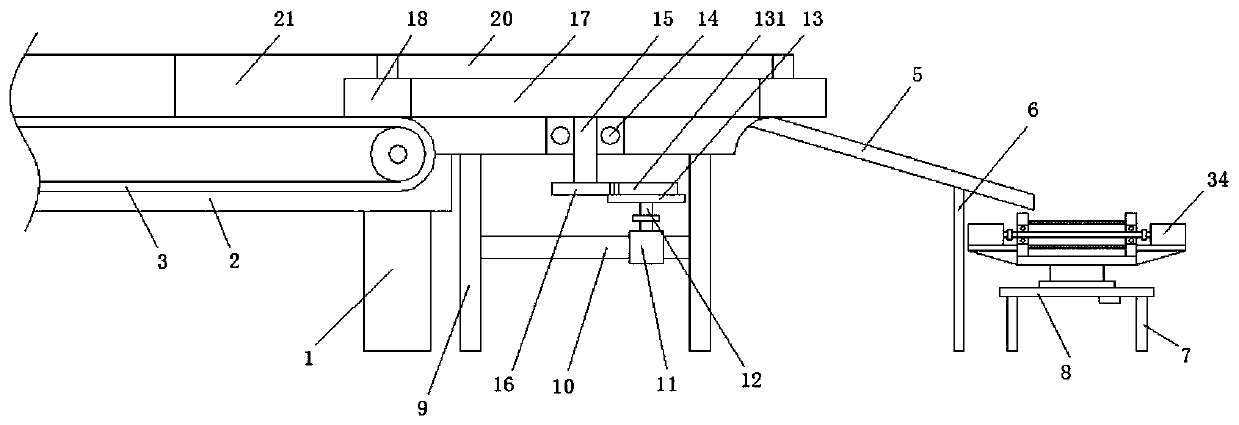

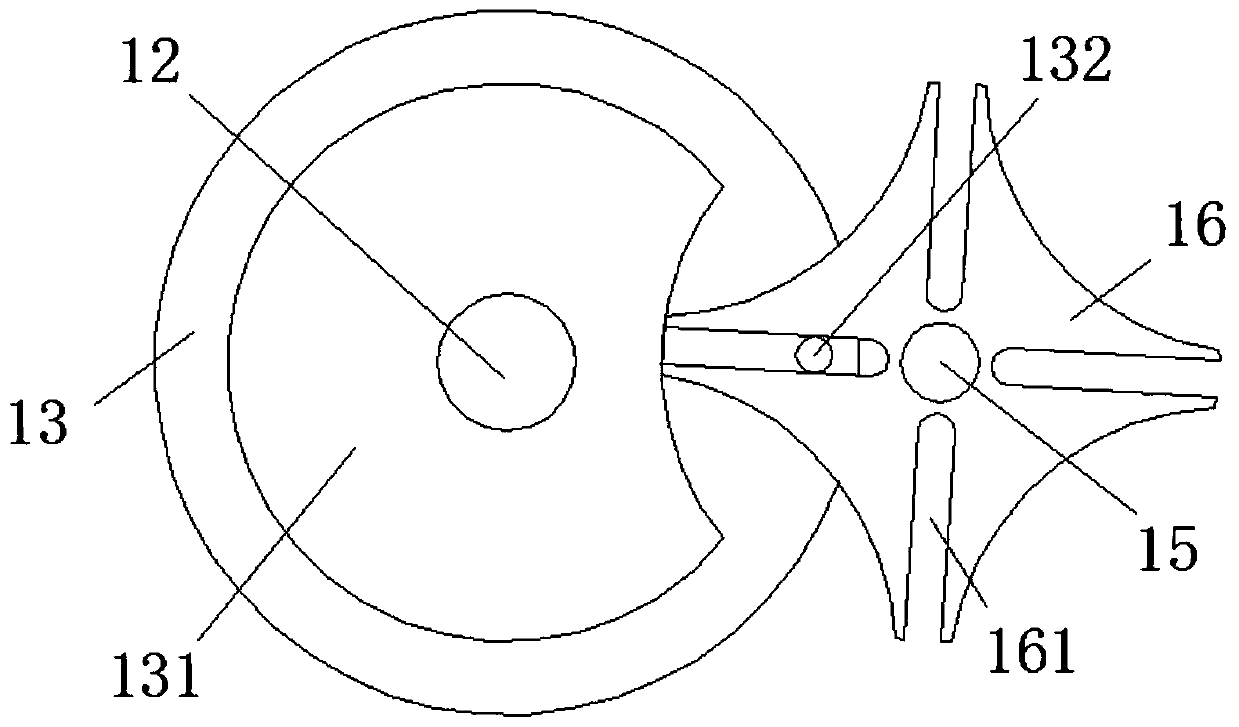

[0037] After the research and analysis of the applicant, this problem occurs (the existing inspection and screening efficiency is low, time-consuming and laborious, the degree of automation is low, and the labor cost is greatly increased). By setting the weighing and screening device, when in use, the intermittent transmission device The weighing and screening device automatically feeds materials intermittently. After the injection molding and casting parts are conveyed to the surface of the screening conveyor belt, the pressure sensor detects and senses the quality of the injection molding and casting parts, and then transmits the information to the programmable PLC controller. The PLC controller automatically controls the start of the second servo motor or the third servo motor according to the preset system value, drives the first rotating shaft or the second rotating shaft to rotate, drives the screening conveyor belt to move, and passes qualified or unqualified products thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com