Magnetic material offline type magnetic separation sliding brush rotary swinging detecting and pipe filling integrated machine

A magnetic material, offline technology, applied in the direction of conveyor, loading/unloading, transportation and packaging, etc., can solve the problems of demagnetization spread, loss, functional consumption of fluid structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

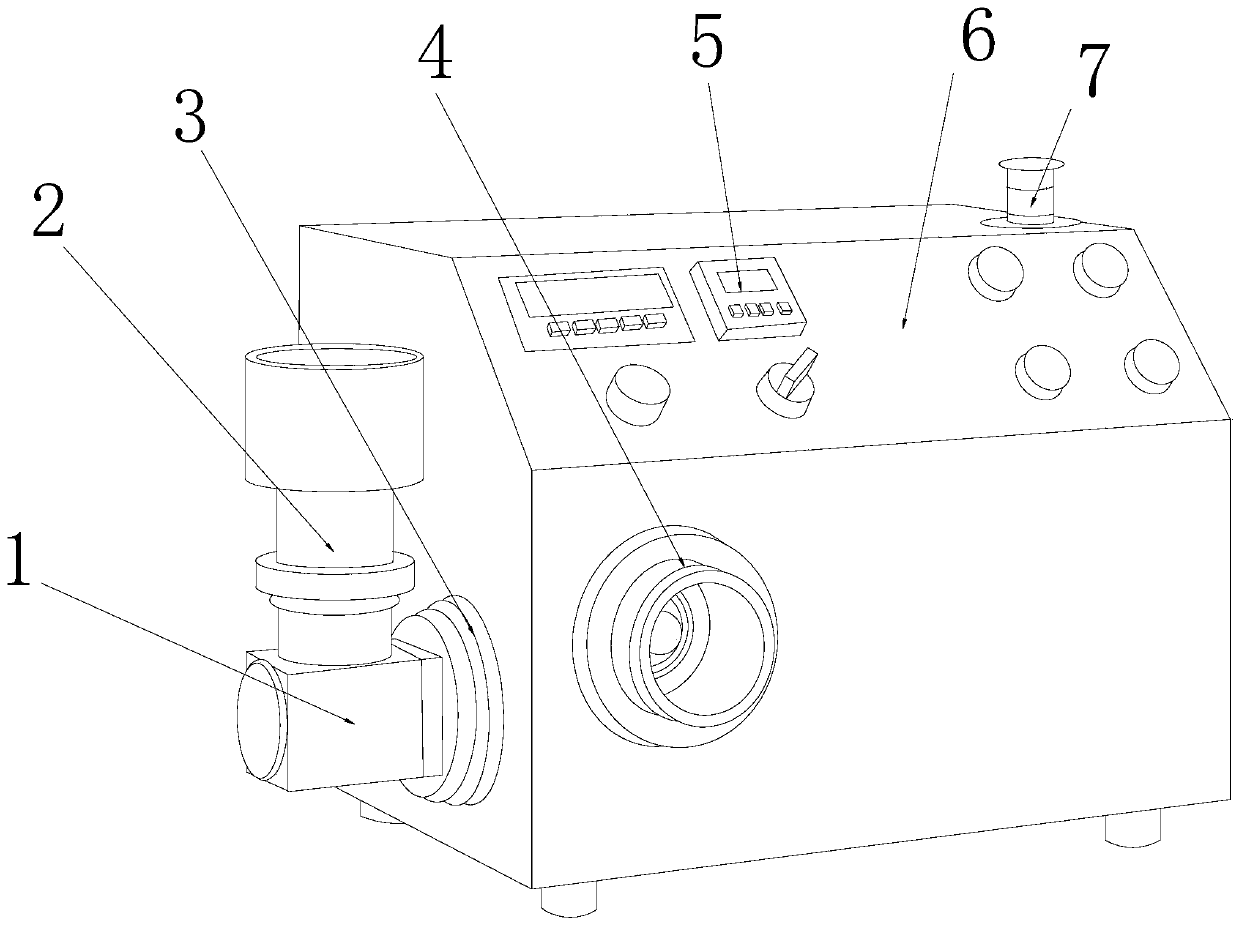

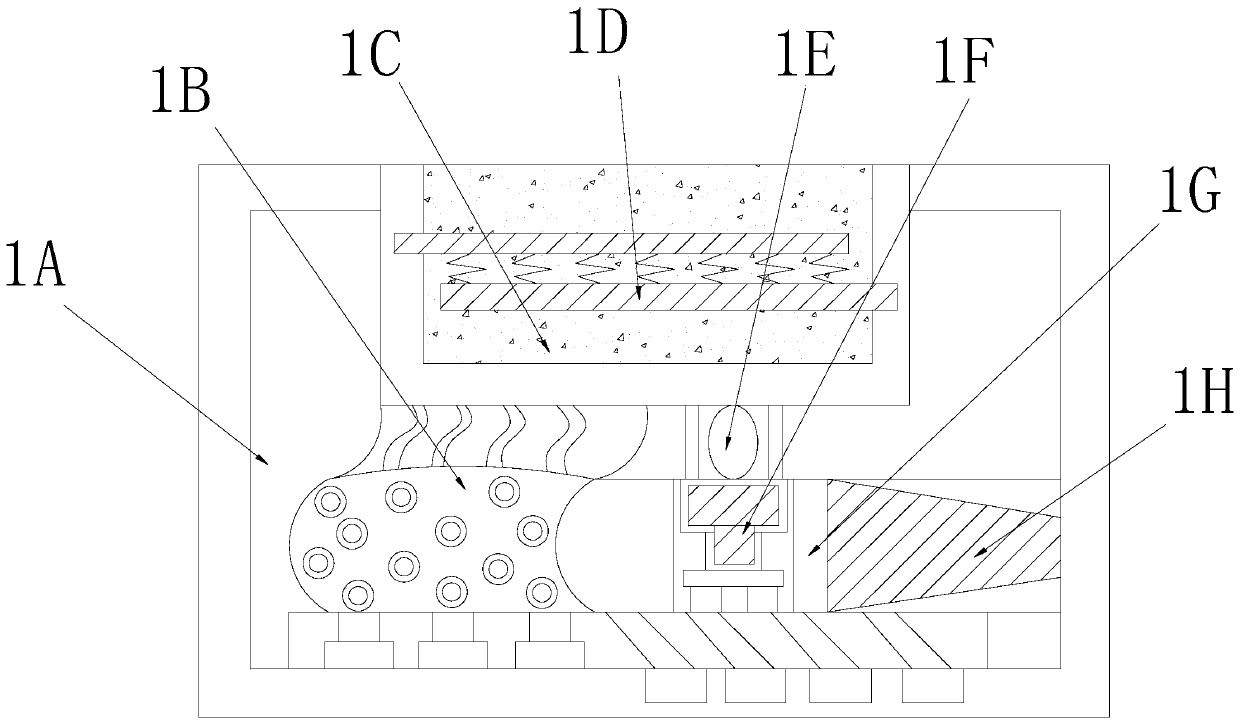

[0034] see Figure 1-Figure 7 , the present invention provides an off-line detection and installation machine for magnetic separation sliding brush swing of magnetic materials, its structure includes: magnetic separation swing rack groove 1, pouring connection groove cylinder 2, flange plate 3, pipe loading and insertion The notch 4, the industrial control panel 5, the power distribution box 6, and the short indicator lamp column 7, the magnetic separation rotary pendulum frame groove 1 is nested under the bottom of the pouring tank 2 and communicates with each other, and the magnetic separation rotary pendulum frame The slot 1 is inserted on the left side of the flange 3 and the axes are co-linear, the tube slot opening 4 is inserted on the left front side of the distribution box 6, and the flange 3 is closely attached to the distribution box 6 The left side of the indicator lamp post 7 is embedded in the upper right corner of the power distribution box 6, the industrial cont...

Embodiment 2

[0041] see Figure 1-Figure 7 , the present invention provides an off-line magnetic-separation brush rotary pendulum detection and tube integration machine for magnetic materials, other aspects are the same as in Embodiment 1, the difference is that:

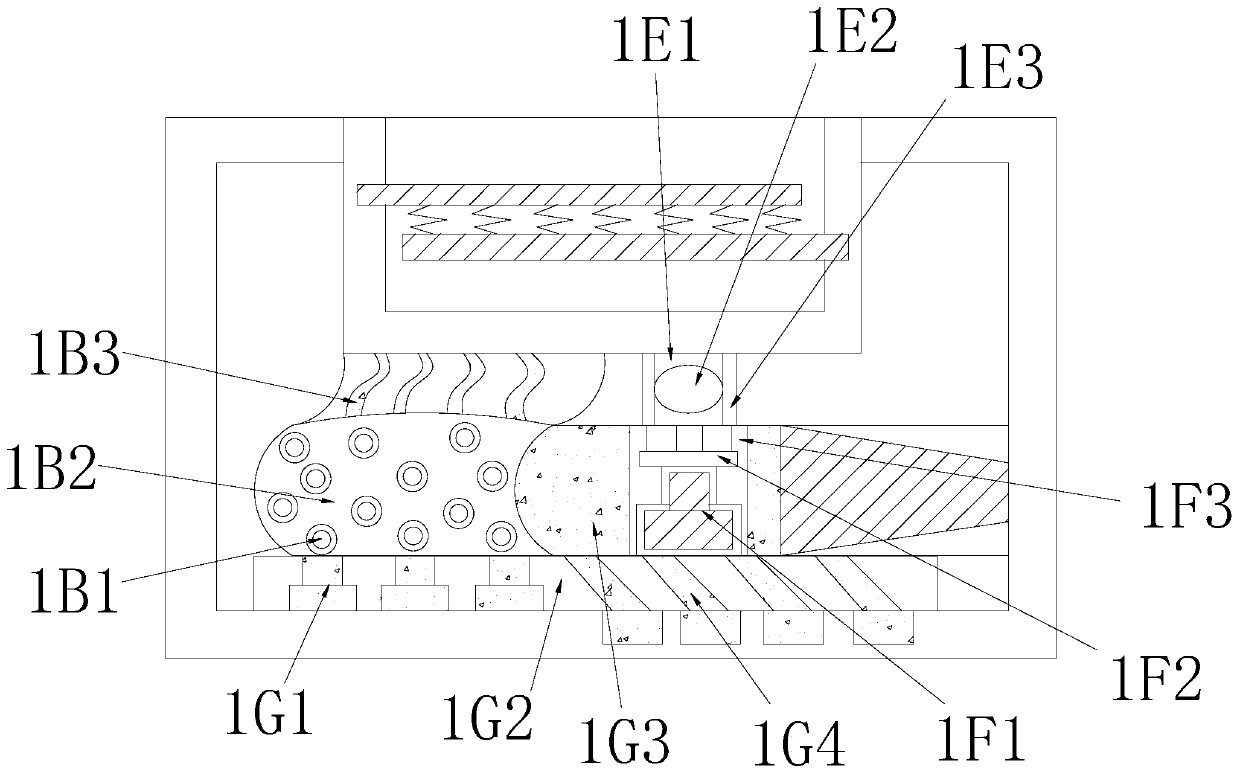

[0042] see image 3 The booster bead groove 1E is composed of an inner chamber 1E1, a booster bead 1E2, and a grid baffle 1E3, and two grid baffles 1E3 are respectively attached to the left and right sides of the inner chamber 1E1 , the booster bead 1E2 is installed inside the inner chamber 1E1 and the axes are collinear, and the booster bead 1E2 is rolled to press the horizontally opposite top grid baffle 1E3 to achieve the supporting force protection effect of auxiliary limit, so that the top The inner activity space is limited, and the compression expansion of the inner air pressure is improved.

[0043] see Figure 5 , the booster ball 1E2 is composed of a crescent weight 1E21, a spring wire 1E22, a core block 1E23, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com