In-situ sewage and odor treatment device for sewage treatment plant

A sewage treatment plant and treatment device technology, applied in gas treatment, aerobic and anaerobic process treatment, chemical instruments and methods, etc., can solve the problems of high total nitrogen in effluent, low denitrification efficiency, insufficient carbon source of domestic sewage, etc. , to achieve the effect of reducing costs and reducing sludge production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

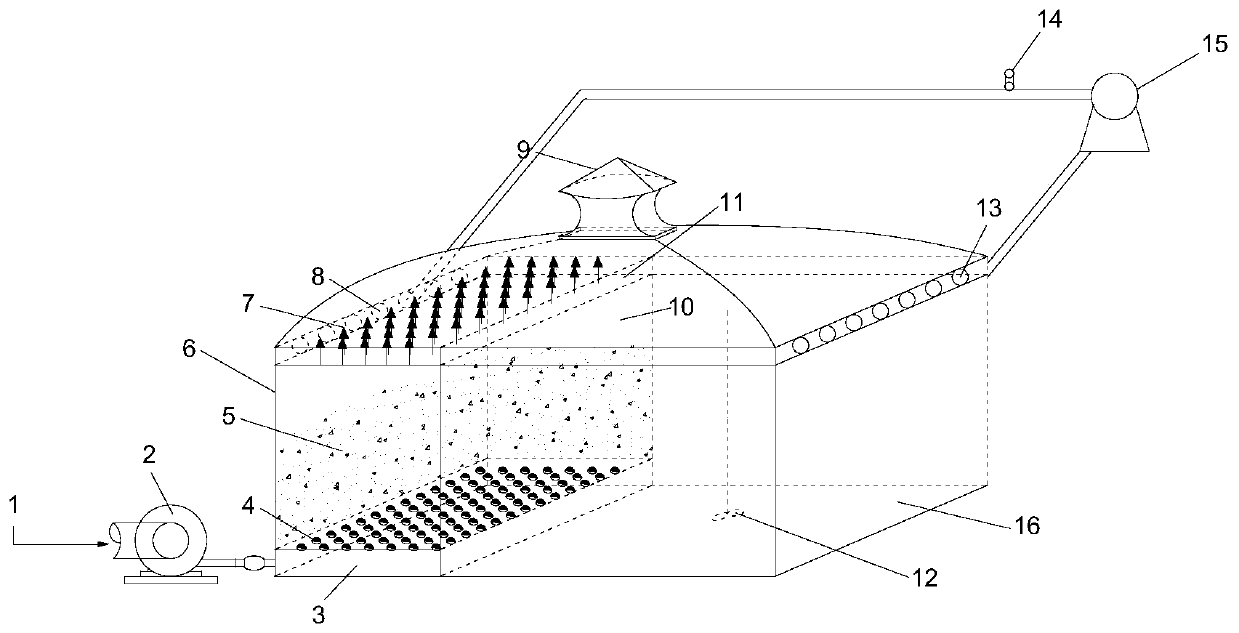

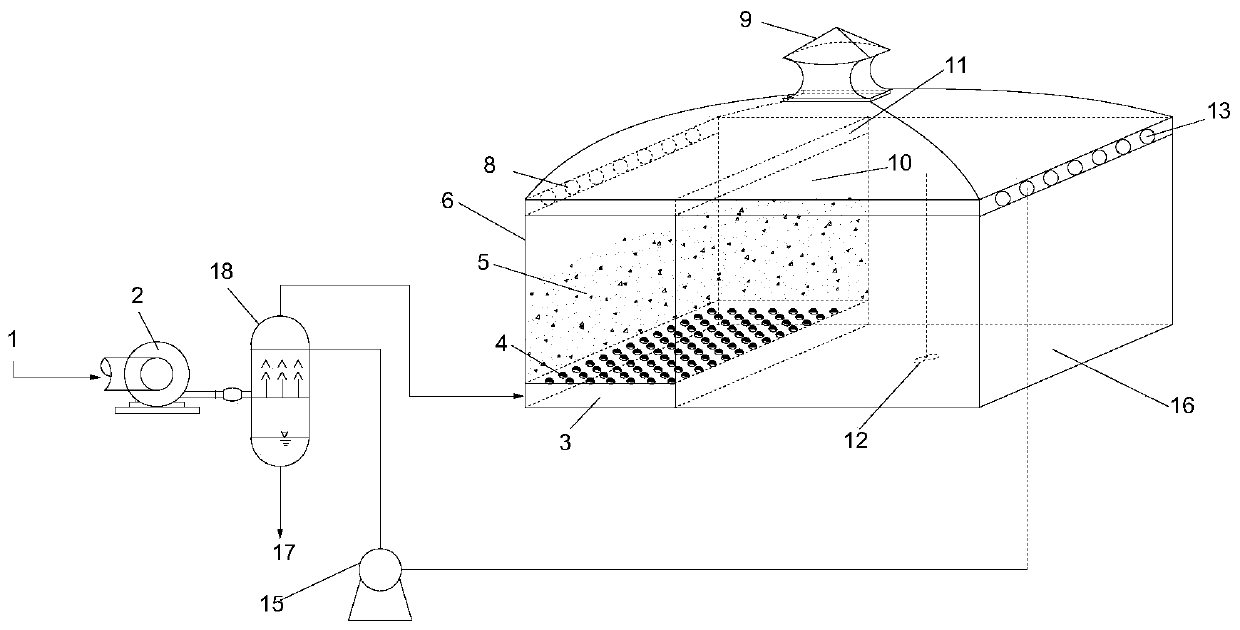

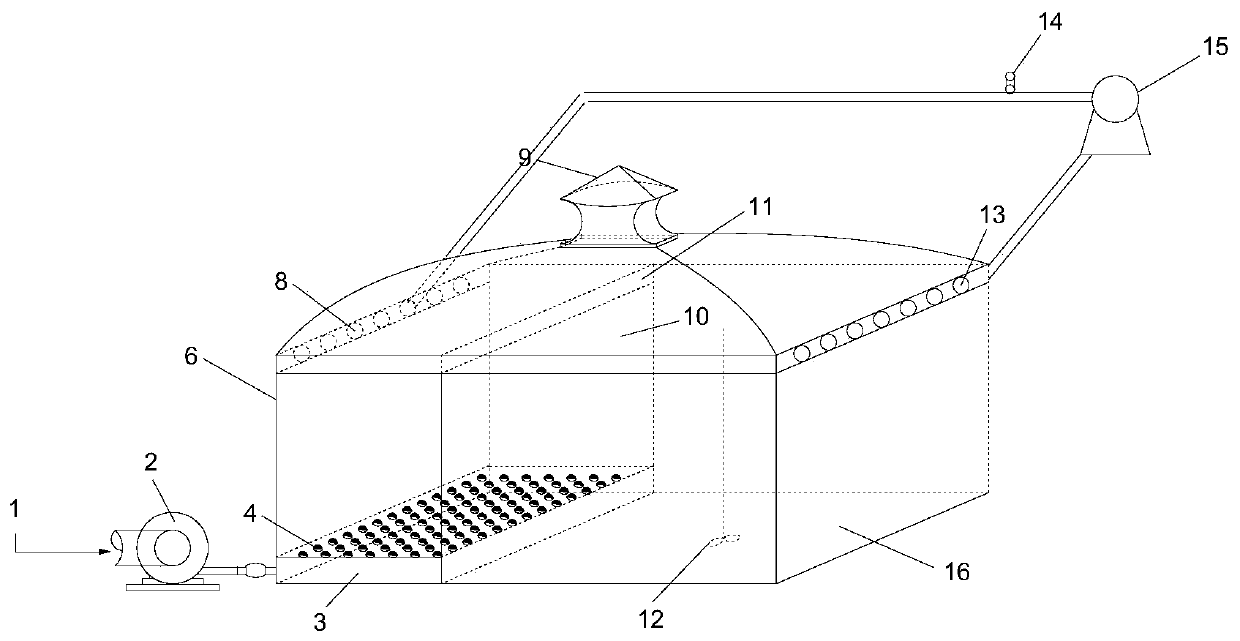

Method used

Image

Examples

Embodiment 1

[0047] Through the simulation experiment of sewage and odor treatment in the sewage treatment plant in the laboratory, that is, after simulating the dissolution of the odor in the sewage treatment plant into the nitrate-containing sewage, the removal performance of sulfide, nitrate and ammonia nitrogen in the sewage was investigated. The range of sulfide concentration tested in this experiment is 60mg / L-540mg / L, the range of nitrate concentration is 10.5mg / L-94.5mg / L, and the range of ammonia nitrogen concentration is 70-80mg / L.

[0048] When the concentrations of sulfide, nitrate and ammonia nitrogen in the influent were 60mg / L, 10.5mg / L and 70.9mg / L respectively, the removal rates of sulfide, nitrate and ammonia nitrogen were 94%, 90% and 13%, respectively. As the influent matrix concentration further increased, the removal rates of sulfide, nitrate and ammonia nitrogen remained above 90%, 89% and 21%, respectively.

[0049] After several experiments, the average removal rat...

Embodiment 2

[0052] Through the simulation experiment of sewage and odor treatment in the sewage treatment plant in the laboratory, that is, after simulating the dissolution of the odor in the sewage treatment plant into the nitrate-containing sewage, the removal performance of sulfide, nitrate and ammonia nitrogen in the sewage was investigated. What this experiment tests is when the influent sulfide concentration is 60mg / L, the nitrate concentration is 10.5mg / L, and the ammonia nitrogen concentration ranges from 72-78mg / L, the long-term effect of the treatment device on sulfide, nitrate and ammonia nitrogen Remove the performance case.

[0053] When the influent sulfide concentration is low, the sulfide removal efficiency of the effluent is stable at more than 90% for many days, and the average removal rate is 94%; the nitrate removal rate is stable at more than 88% for many days, and the average removal rate At the same time, it also has a certain removal effect on ammonia nitrogen, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com