A kind of processing technology of waste magnesia-carbon brick regenerated particles

A technology for the regeneration and treatment of magnesia-carbon bricks, which is applied in the field of refractory material treatment, can solve the problems of unsatisfactory removal of impurities from waste magnesia-carbon bricks, and achieve the effects of low iron content, reduced production costs, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

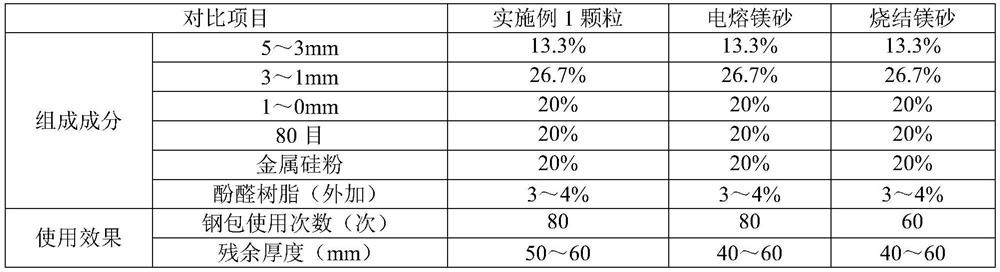

Embodiment 1

[0026] A treatment process for recycled particles of waste magnesia-carbon bricks, specifically as follows: First, manually classify waste magnesia-carbon bricks used in metallurgical furnaces such as ladles or converters according to different materials: magnesia-carbon, aluminum-carbon, aluminum-magnesium-carbon and aluminum-carbonized Magnesia bricks, of which magnesia-carbon and aluminum-magnesia-carbon are collectively referred to as magnesia bricks; then manually hammer and braze the magnesia bricks one by one to remove iron smelting slag iron, metamorphic layer, oxidized loose layer and sundries on the surface Adhesion layer, this step is rough treatment of magnesia bricks; the rough treatment of magnesia bricks is processed and crushed by jaw crusher (PE-400 / 600 type), and then sent to double roll crusher (2PG0640 type) for processing , the crushing particle size is required to be 0-10mm. The crushed magnesia brick particles are passed through a vibrating screen, and th...

Embodiment 2

[0028] A treatment process for recycled particles of waste magnesia-carbon bricks, specifically as follows: First, manually classify waste magnesia-carbon bricks used in metallurgical furnaces such as ladles or converters according to different materials: magnesia-carbon, aluminum-carbon, aluminum-magnesium-carbon and aluminum-carbonized Magnesia bricks, of which magnesia-carbon and aluminum-magnesia-carbon are magnesia bricks; then manually hammer and braze the magnesia bricks one by one to remove iron smelting slag iron, metamorphic layer, oxidized loose layer and sundries on the surface Layer, this step is rough treatment of magnesia bricks; the rough treatment of magnesia bricks is processed and crushed by jaw crusher (PE-400 / 600 type), and then sent to twin-roller crusher (2PG0640 type) for processing. The crushing particle size is required to be 0-10mm. After the crushed magnesia brick particles pass through the vibrating screen, the particles larger than 10mm are sieved ...

Embodiment 3

[0030] This example is a comparative example. Its raw materials and steps are roughly the same as those in Example 2, and the similarities will not be repeated. The difference is that the particles after iron removal are placed in the storage bin for atomization. The liquid is clear water, and it is advisable for the atomization to wet all the particles, trap for 48 hours, and then undergo the same roasting, rolling, screening and iron removal to obtain regenerated particles.

[0031] The regenerated particles of waste magnesia-carbon bricks prepared in this example were tested, and the result was: the particles of the metamorphic layer of particles processed in this example were not fully removed, and the iron content was 1.2, which was lower than that of Example 1 and Example 2. , did not meet the predetermined requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com