Photo-thermal patterned self-reinforced polymer material and preparation method thereof

A polymer material and patterning technology, applied in the field of photothermal patterning self-reinforced polymer materials and their preparation, can solve the problems of inability to deform and bend as required, hard materials are difficult to process and shape, and the shape is difficult to maintain, and the preparation method is achieved. Simple and easy to operate, high temperature, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

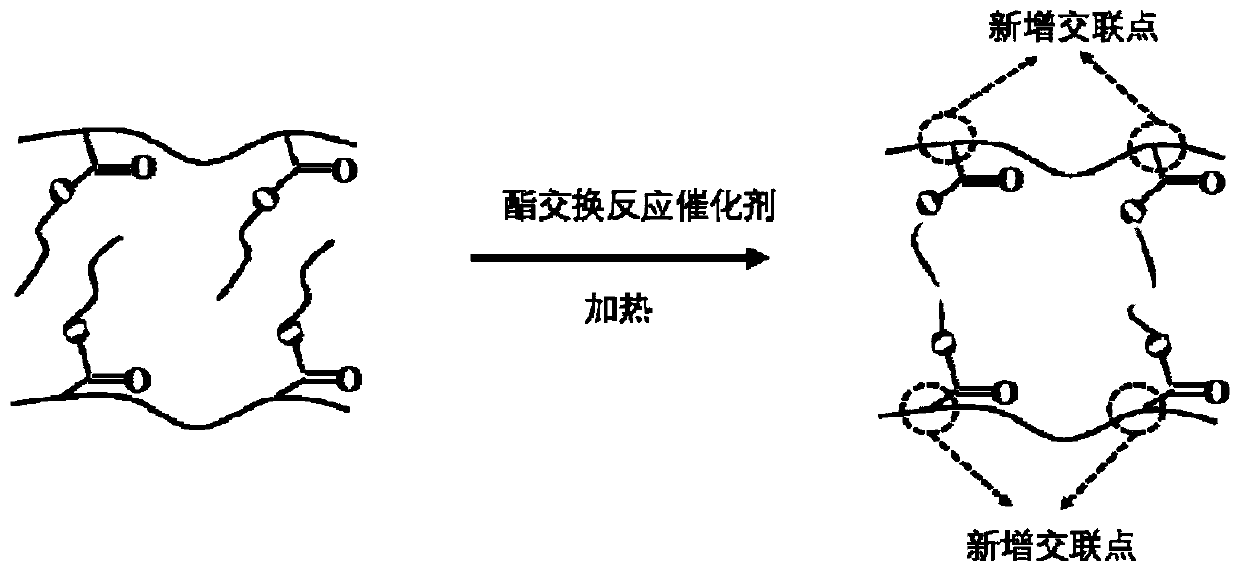

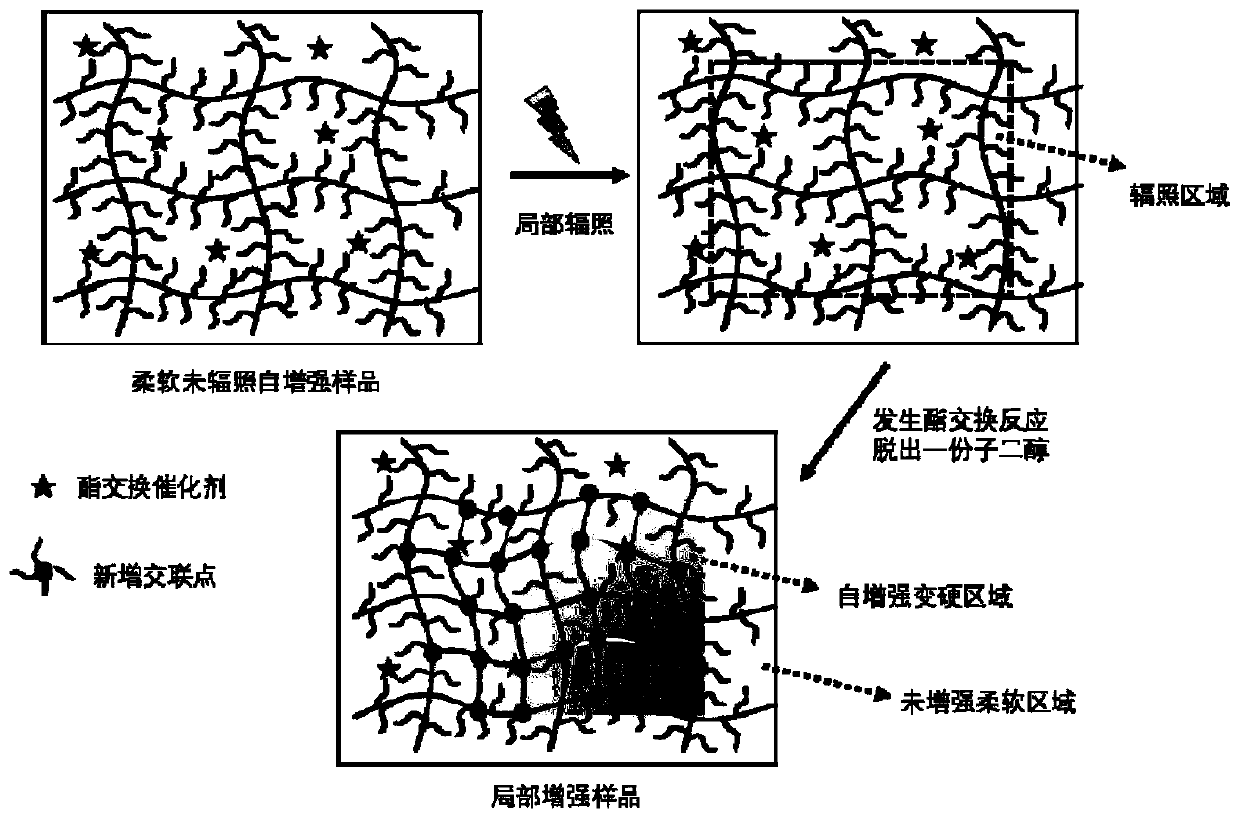

Method used

Image

Examples

Embodiment 1

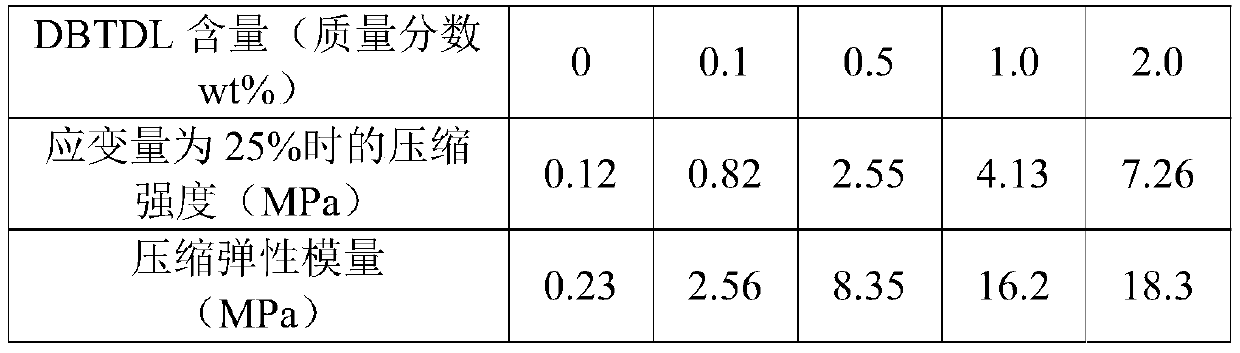

[0036] A photothermal patterned self-reinforced polymer material, which includes the following raw materials: calculated by mass percentage, 97.9% of monomers containing ester bonds in the side chain after polymerization, 1% of initiator, 1% of transesterification catalyst and crosslinking agent 0.1%.

[0037] The acrylate monomer is hydroxybutyl acrylate.

[0038] The initiator is azobisisobutyronitrile.

[0039] The transesterification catalyst is dibutyltin dilaurate.

[0040] A method for preparing a photothermal patterned self-reinforced polymer material, comprising the following steps:

[0041] (1) Mix the above-mentioned monomers, initiators, transesterification catalysts and crosslinking agents, pour them into polytetrafluoroethylene molds after defoaming, and obtain prepolymerized materials through bulk free radical polymerization at 60°C;

[0042] (2) The self-reinforced polymer material can be obtained by heating the pre-polymerized material in an oven at 150° C....

Embodiment 2

[0044] A photothermal patterned self-reinforcing polymer material, which includes the following raw materials: calculated by mass percentage, 98% of monomers containing ester bonds in the side chain after polymerization, 0.45% of initiators, 1% of transesterification catalysts and crosslinking agents 0.55%.

[0045] The acrylate monomer is hydroxybutyl acrylate.

[0046] The initiator is azobisisobutyronitrile.

[0047] The transesterification catalyst is dibutyltin dilaurate.

[0048] A method for preparing a photothermal patterned self-reinforced polymer material, comprising the following steps:

[0049] (1) Mix the above-mentioned monomers, initiators, transesterification catalysts and crosslinking agents, pour them into polytetrafluoroethylene molds after defoaming, and obtain prepolymerized materials through bulk free radical polymerization at 60°C;

[0050] (2) The self-reinforced polymer material can be obtained by heating the pre-polymerized material in an oven at 180...

Embodiment 3

[0052] A photothermal patterned self-reinforcing polymer material, which includes the following raw materials: calculated by mass percentage, 94% of monomers containing ester bonds in the side chain after polymerization, 1% of initiator, 4% of transesterification catalyst and crosslinking agent 1%.

[0053] The acrylate monomer is hydroxyethyl acrylate.

[0054] The initiator is azobisisobutyronitrile.

[0055] The transesterification catalyst is 1,5,7 triazidebicyclo(4.4.0)dec-5-ene.

[0056] A method for preparing a photothermal patterned self-reinforced polymer material, comprising the following steps:

[0057] (1) Mix the above-mentioned monomers, initiators, transesterification catalysts and crosslinking agents, pour them into polytetrafluoroethylene molds after defoaming, and obtain prepolymerized materials through bulk free radical polymerization at 60°C;

[0058] (2) Heating the pre-polymerized material in an oven at 120° C. for 18 hours to obtain a photothermally p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com