Secondary starting method for shield in single-hole single-line underground excavation tunnel

It is a technique of underground excavation in tunnels, which is applied in the direction of tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve the problems of reduced advantages of shield tunneling methods, weakened economic benefits, and the addition of shield tunnels, and achieves good prospects for popularization and application. The effect of considerable economic benefits and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

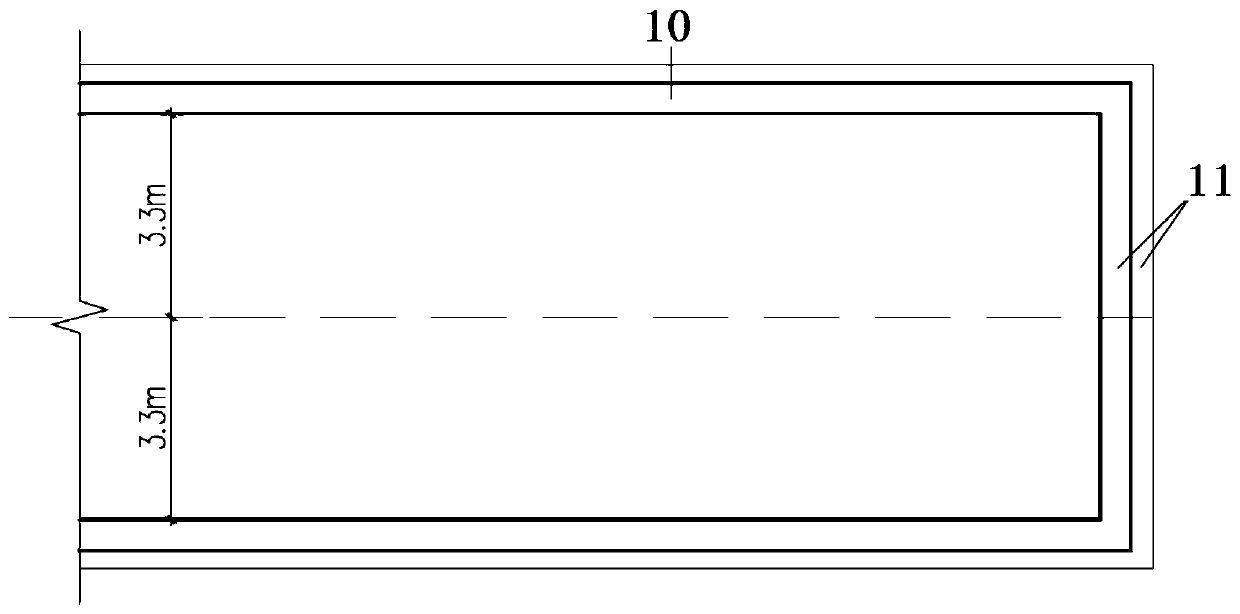

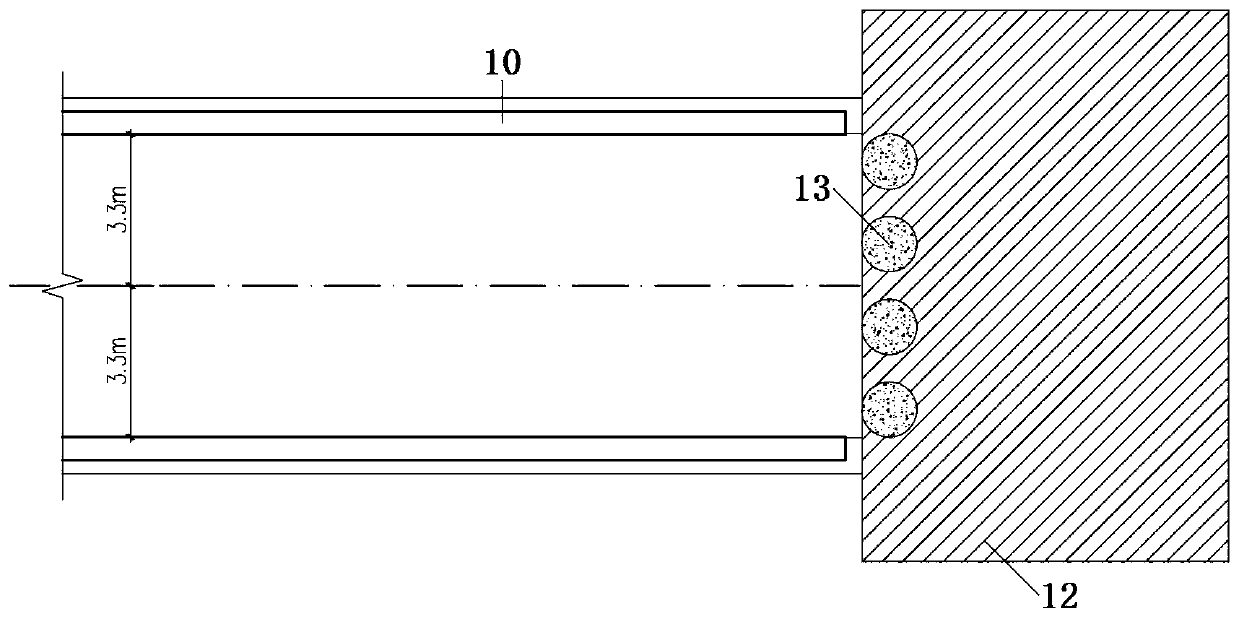

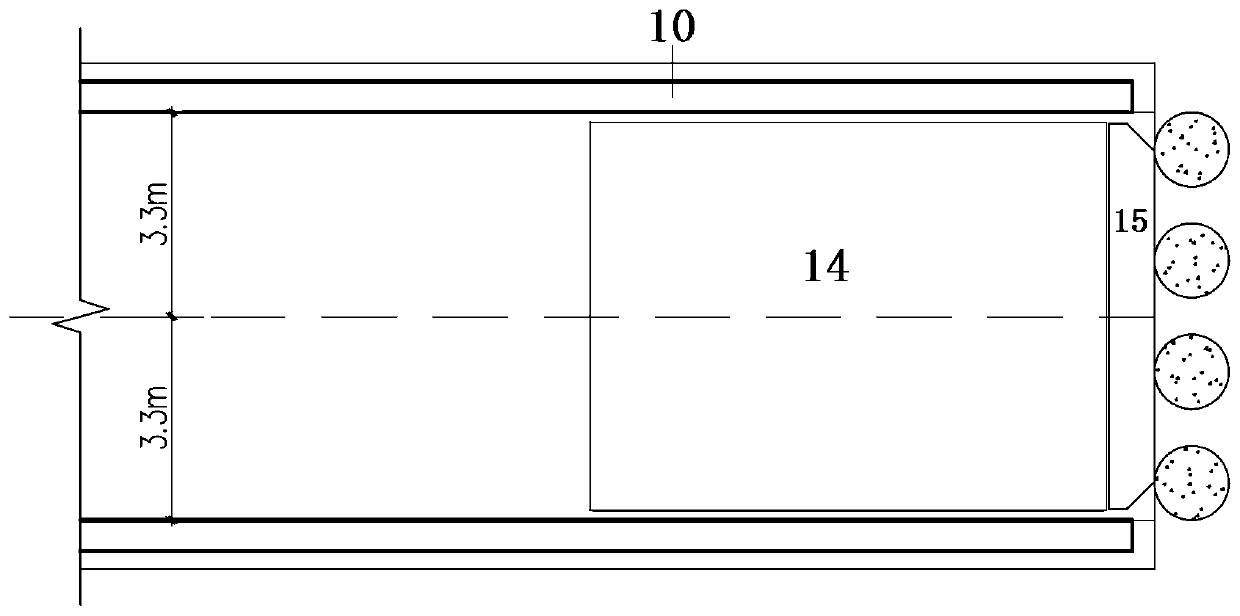

[0029] see Figure 1 to Figure 6 , which shows the method for secondary initiation of shield tunneling in a single-hole single-line underground excavation tunnel of the present invention.

[0030] The method for secondary initiation of shield tunneling in the single-hole single-line underground excavation tunnel includes the following steps:

[0031] Step 1: See figure 1 , using the underground excavation method to construct a single-hole single-track tunnel. During the construction, the construction of the tunnel body 10 and the end wall 11 of the tunnel section is completed, and the distance between the tunnel body 10 and the center line of the line can be 3.3m (the shield machine with an outer diameter of 6m is example), so that the conditions for shield passage can be reserved (0.3-0.4m of clearance in the underground excavation section is placed outside, and the guide platform steel plate is pre-embedded at the inverted arch), wherein, the construction of the tunnel body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com