Permanent magnet biased magnetic suspension bearing

A technology of magnetic suspension bearing and permanent magnet bias, which is applied to the components of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc., can solve the problem of reducing the safety margin of rotor dynamics and limiting electronic power Device selection, increasing the rotor surface linear velocity, etc., to achieve the effects of compact structure, increased application scope, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

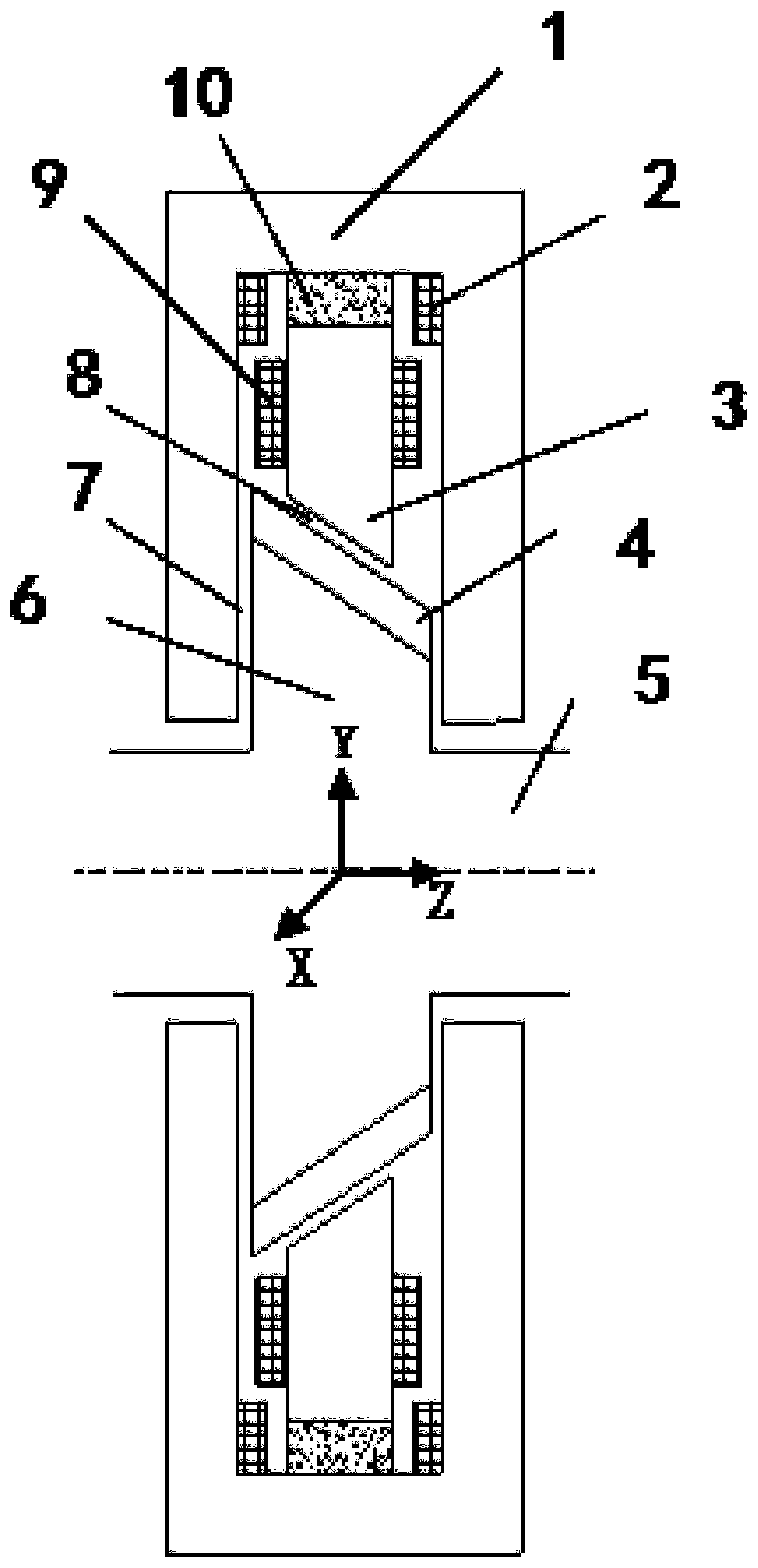

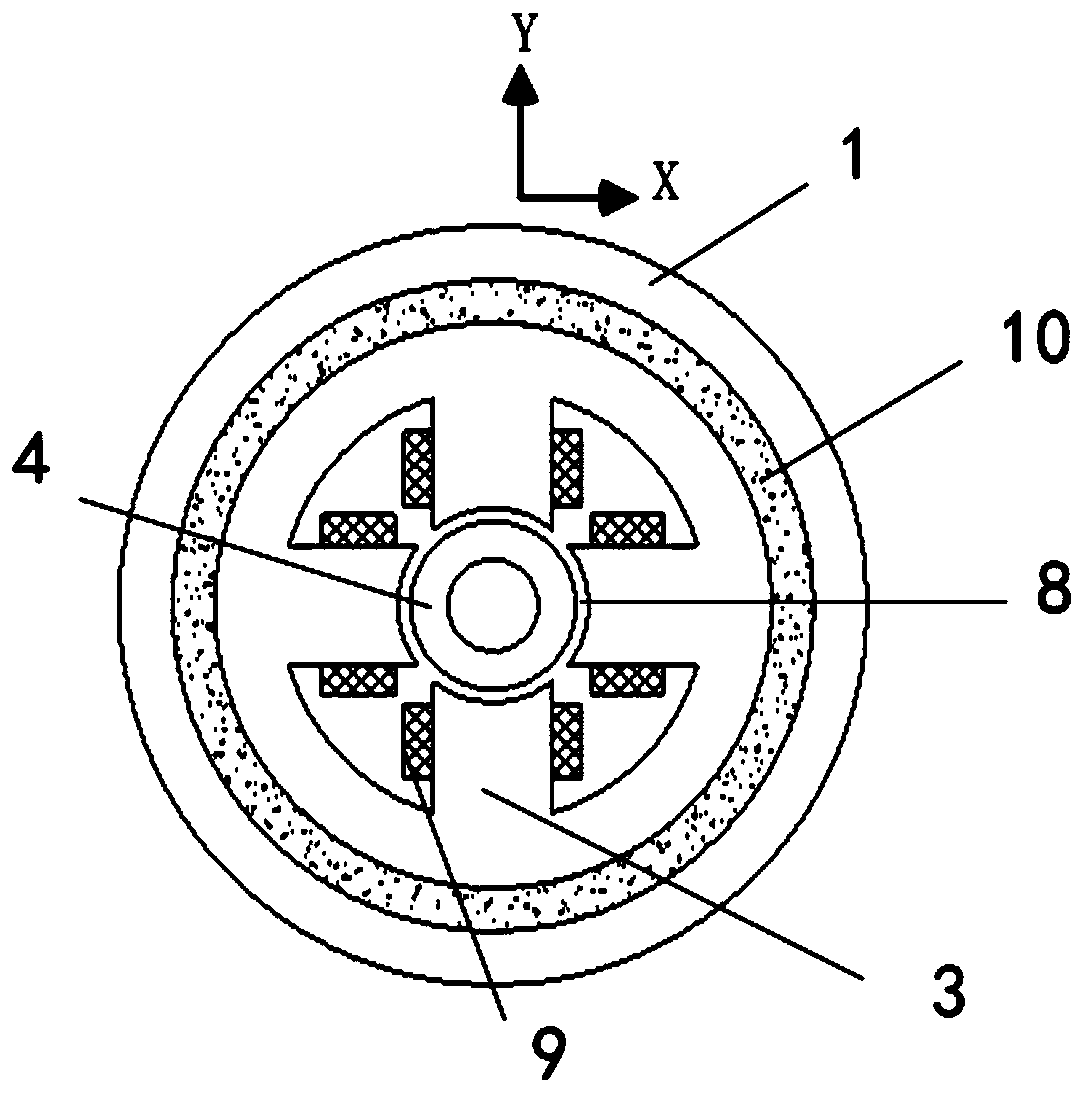

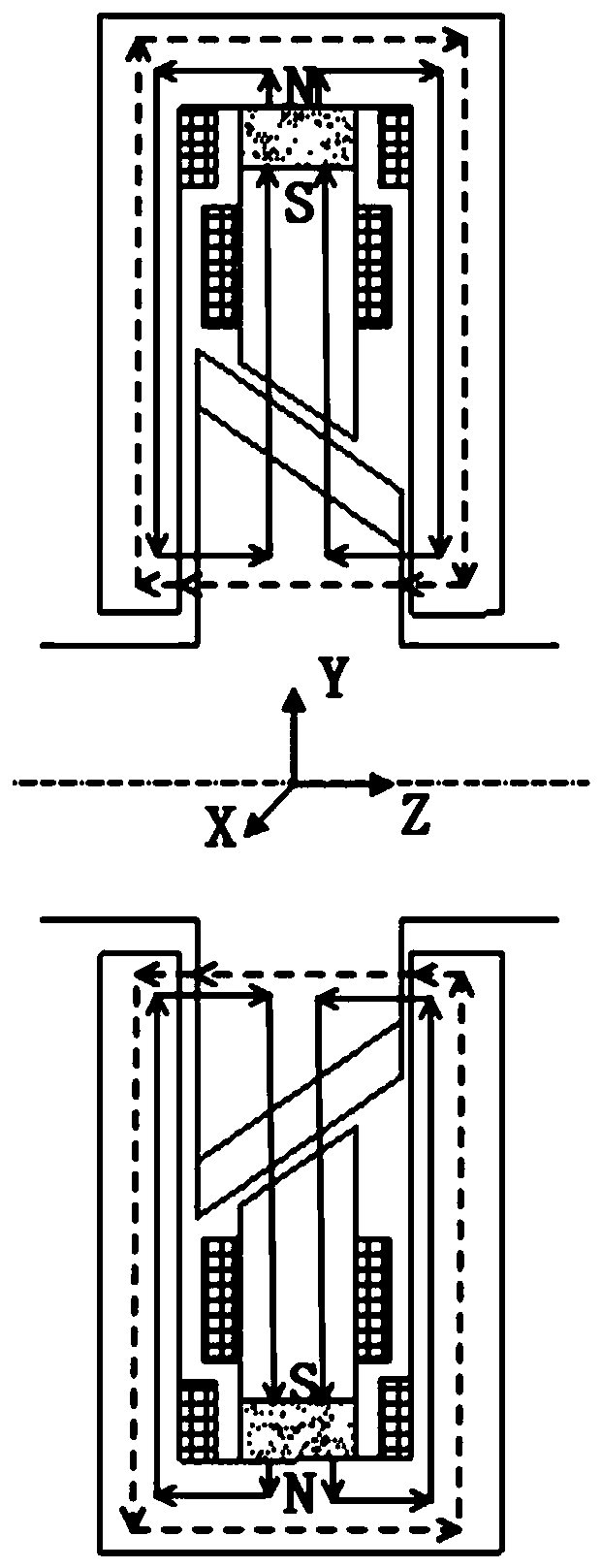

[0025] Such as figure 1 , figure 2 As shown, the basic form of the present invention is: axial magnetic guide ring 1, axial coil 2, radial coil 9, conical rotor lamination 4, conical thrust disc 6, rotor shaft 5, a conical radial stator iron Core 3, a ring 10 of permanent magnets. The axial magnetic guide ring 1 and the inner tapered radial stator core 3 are connected through the permanent magnet ring 10, which is radially magnetized and provides axial and radial bias magnetic fields at the same time; the conical thrust The front and back of the disk 6 are planes, forming an axial magnetic gap with the axial magnetic guide ring 1; two sets of axial coils are respectively located on the upper and lower sides of the axial magnetic guide ring 1 to provide an axial control magnetic field; the tapered radial stator core 3 It is made of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap