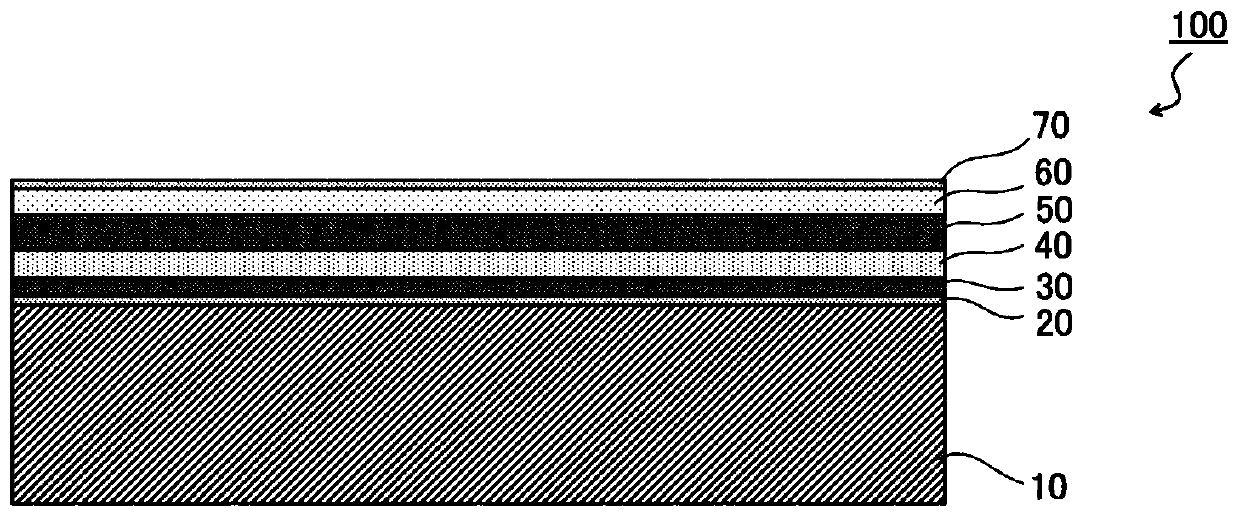

Antireflection film

An anti-reflection and thin-film technology, which is applied in optics, instruments, optical components, etc., can solve the problem of easy coloring of reflection hue and achieve excellent reflection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

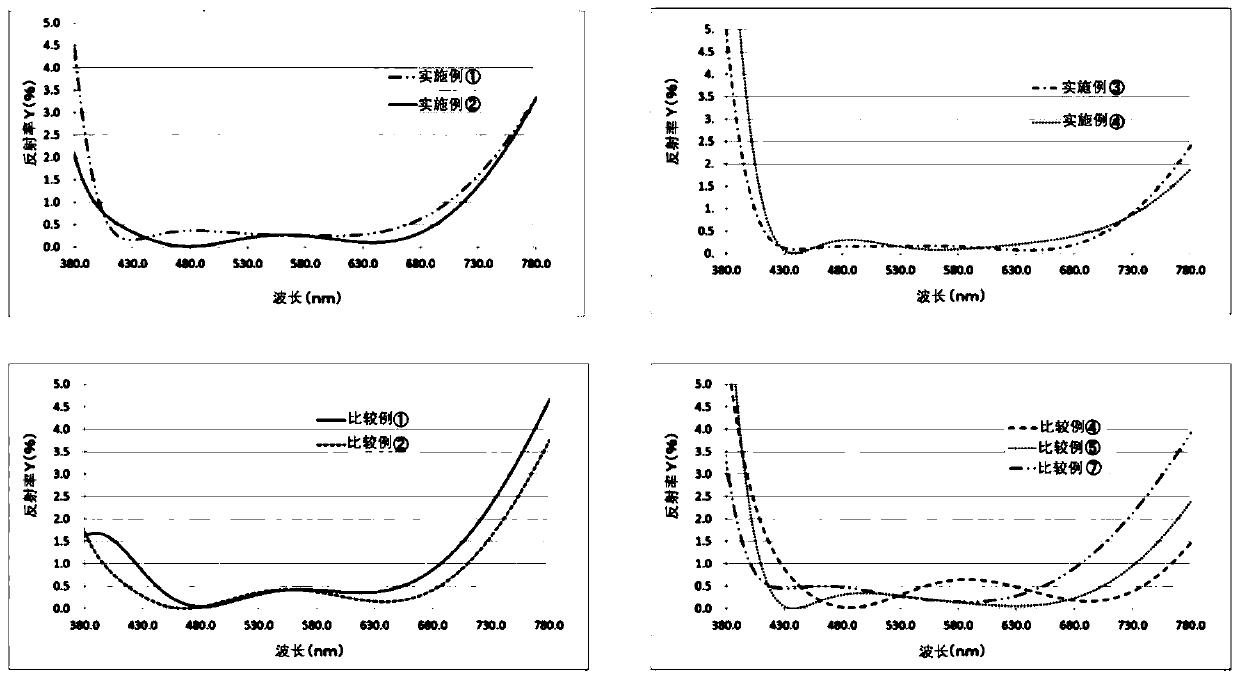

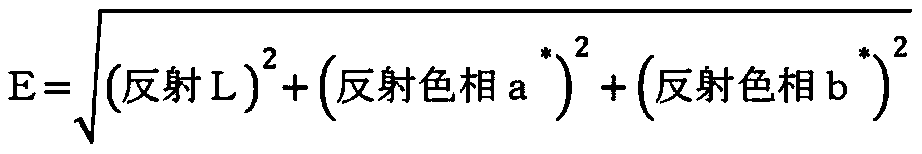

Examples

Embodiment 1

[0093] (production of transparent base material)

[0094] 100 parts by weight of urethane acrylate resin (manufactured by Dainippon Ink Chemical Industry Co., Ltd., trade name "UNIDICV4025", refractive index: 1.52), as inorganic particles, nano-silica particles (manufactured by Nissan Chemical Industry Co., Ltd., trade name " MEK-ST-L", 50 parts by weight of the average particle diameter (50nm), and 5 parts by weight of the brand name "Irgacure 184" manufactured by BASF Corporation as a UV initiator were mixed. Next, a mixed solution of MEK and PGM as a diluting solvent was added to the above-mentioned solution, and the solvent ratio was adjusted so that MEK / PGM=40 / 60, and the composition for hard-coat layer formation was obtained.

[0095] The composition for forming a hard coat layer was applied to one side of a resin film (TAC: manufactured by Fuji Film Co., Ltd., trade name "TD80UL") so that the thickness after drying was 5 μm, and dried at 80° C. for 2 minutes. Then use ...

Embodiment 2~6、 comparative example 1~6

[0105] will first Nb 2 o 5 layer, the first SiO 2 layer, second Nb 2 o 5 layer, the second SiO 2 Except that the thickness of the layer and the antifouling layer was set to the thickness shown in Table 1, it carried out similarly to Example 1, and obtained the antireflection film. The obtained antireflection film was subjected to the above-mentioned evaluation. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com