Preparation method of greater omentum acellular matrix and construction method of cartilage tissue

A technology of decellularized matrix, construction method, applied in the field of tissue engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

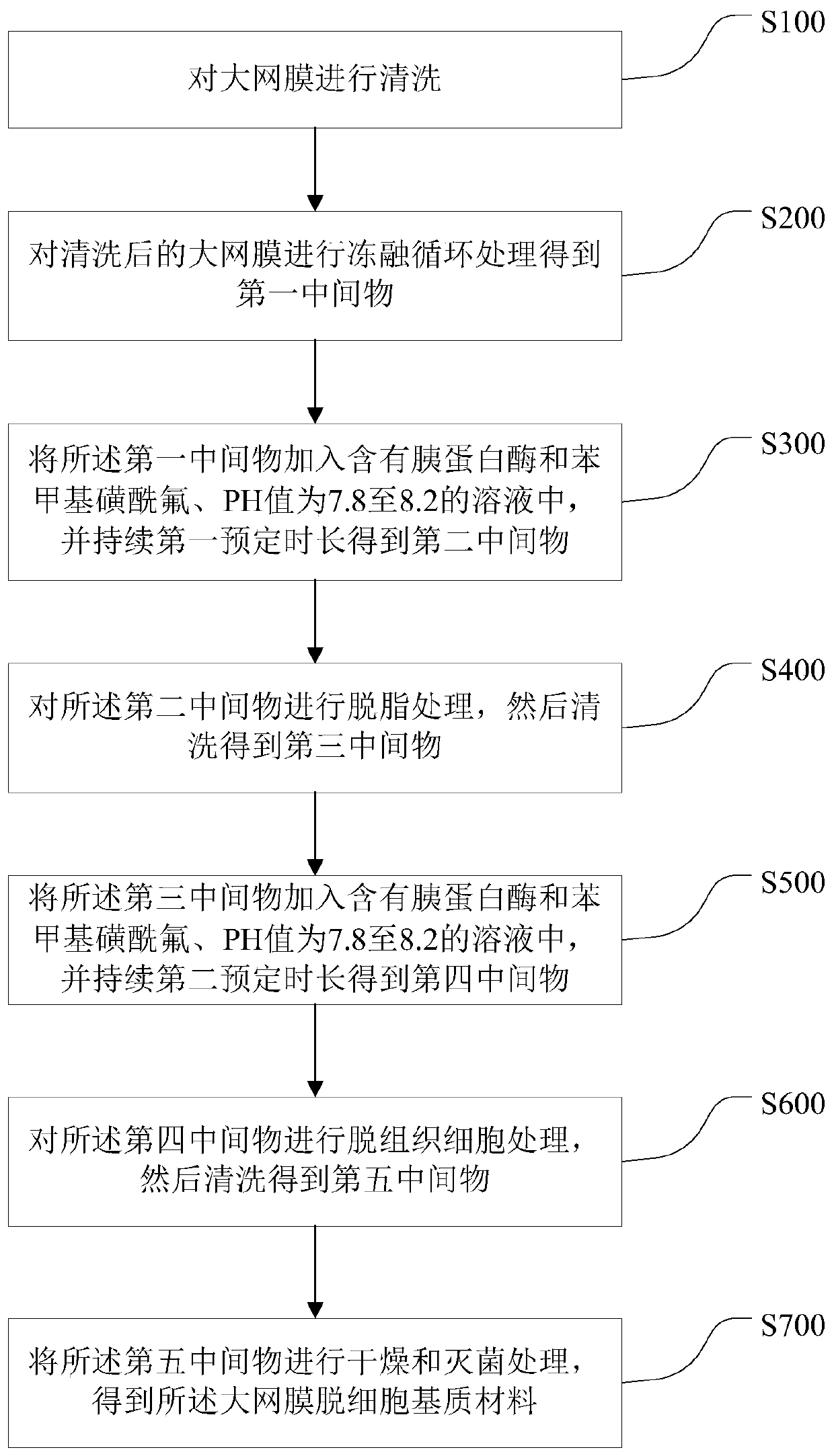

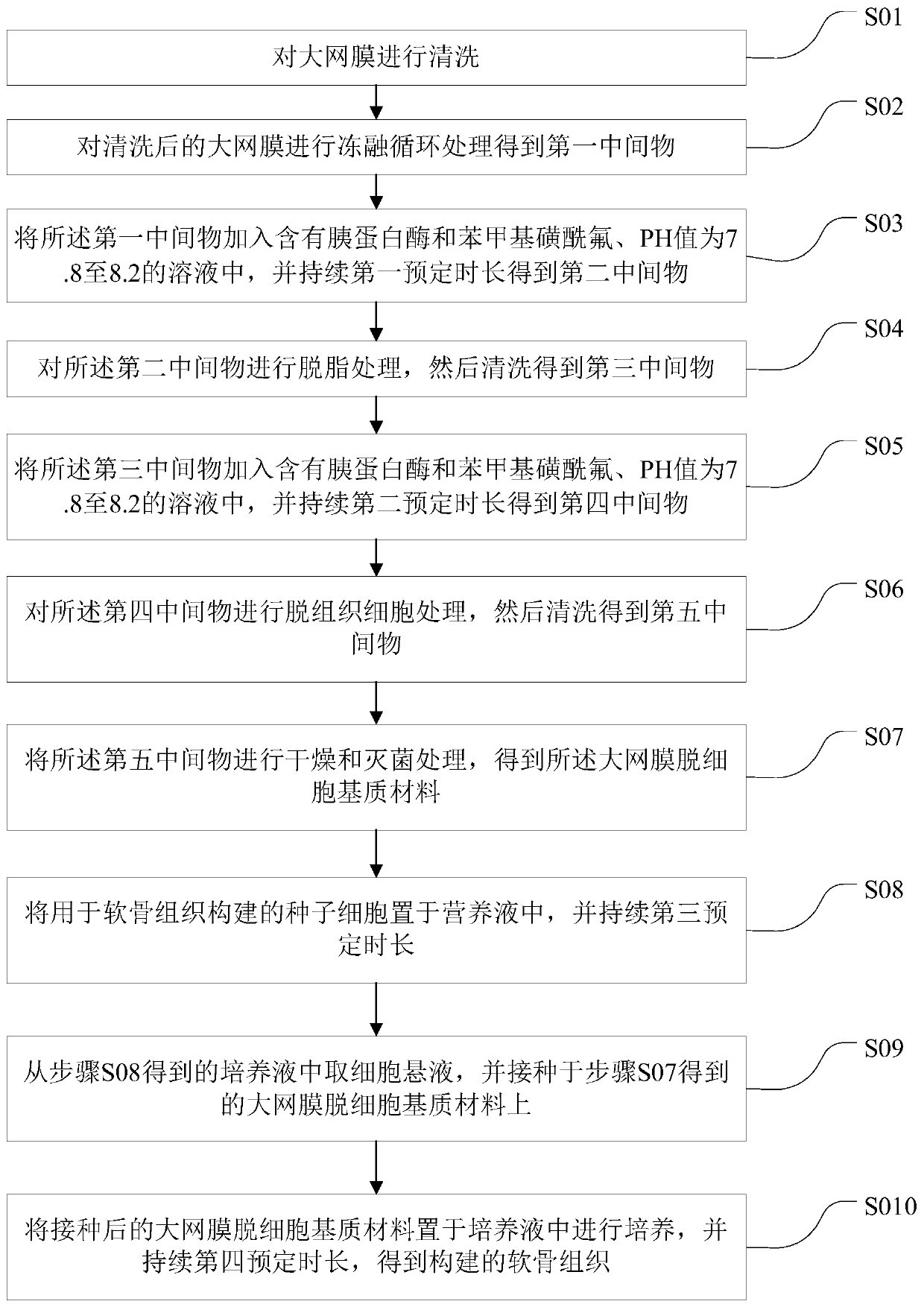

preparation example Construction

[0097] Due to the characteristics of cartilage tissue, the omentum acellular matrix material prepared by the existing method is not suitable for the regeneration of cartilage tissue. Based on this, the application provides a preparation method of the omentum acellular matrix material. Of course It can be understood that the omentum acellular matrix material prepared by the preparation method provided in this application is especially suitable for the regeneration culture of cartilage tissue, and of course, it can also be applied to the regeneration culture of other tissues. like figure 1 Shown, this preparation method comprises steps:

[0098] S100, cleaning the omentum;

[0099]S200, performing freeze-thaw cycles on the washed omentum to obtain a first intermediate;

[0100] S300, adding the first intermediate to a solution containing trypsin and phenylmethylsulfonyl fluoride, with a pH value of 7.8 to 8.2, and continuing for a first predetermined period of time to obtain a...

Embodiment 1

[0107] Fresh porcine omentum was washed 3 times with normal saline;

[0108] Add the washed omentum to a pH containing 10mmol / L trishydroxymethylaminomethane (Tris), 10mmol / L ethylenediaminetetraacetic acid (EDTA) and 1% by mass percent phenylmethylsulfonyl fluoride (PMSF). 3 freeze-thaw cycles in the buffer solution of =8.0, wherein, in one freeze-thaw cycle, the freezing temperature is -80°C, the duration is 1 hour, and the melting temperature is 37°C, and the duration is 0.5 hour;

[0109] The tissue after freeze-thaw cycle treatment was added to a solution containing 0.25% trypsin by mass percentage, 0.1% ethylenediaminetetraacetic acid (EDTA) by mass percentage, and 1% phenylmethylsulfonyl fluoride (PMSF) by mass percentage. Shake at 37°C for 12 hours;

[0110] The tissues obtained in the previous steps were added to isopropanol and degreased by shaking at 37°C for 48 hours, and then phosphate-buffered saline PBS (8g / L NaCl, 200mg / L KCl, 1g / L NaCl, pH=8.0 2 HPO 4 , 200...

Embodiment 2

[0115] Fresh porcine omentum was washed 3 times with normal saline;

[0116] Add the washed omentum to a pH containing 1mmol / L trishydroxymethylaminomethane (Tris), 1mmol / L ethylenediaminetetraacetic acid (EDTA) and 0.1% by mass phenylmethylsulfonyl fluoride (PMSF). 3 freeze-thaw cycles in the buffer solution of =7.8, wherein, in one freeze-thaw cycle, the freezing temperature is -20°C and the duration is 8 hours, and the melting temperature is 30°C and the duration is 1 hour;

[0117] The tissue after freeze-thaw cycle treatment was added to a solution containing 0.1% trypsin by mass percentage, 0.01% ethylenediaminetetraacetic acid (EDTA) by mass percentage, and 0.1% phenylmethylsulfonyl fluoride (PMSF) by mass percentage. Shake at 30°C for 6 hours;

[0118] The tissues obtained in the previous steps were added to isopropanol and degreased by shaking at 30°C for 40 hours, and then phosphate-buffered saline PBS (8g / L NaCl, 200mg / L KCl, 1g / L NaCl, pH=7.8 2 HPO 4 , 200mg / L K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com