An energy-saving wet flue gas, sulfur and dust integrated ultra-low emission process

A flue gas sulfur and energy-saving technology, which is applied in the field of energy-saving wet flue gas, sulfur and dust integrated ultra-low emission process, can solve the problems of inability to accurately match coal-fired generating units, energy waste, etc., so as to avoid waste of power consumption during operation. , the effect of saving power consumption and equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

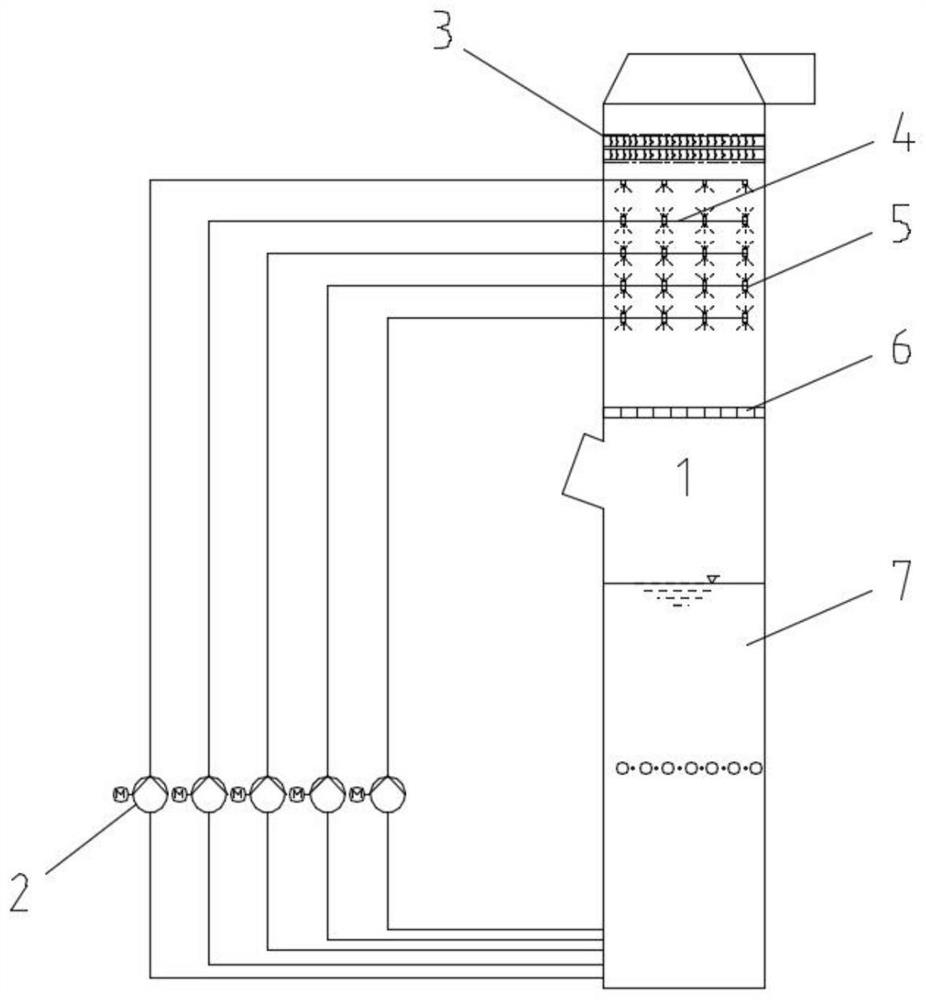

[0027] This embodiment is an energy-saving wet flue gas, sulfur and dust integrated ultra-low emission process, such as figure 1 As shown, it includes a desulfurization tower 1, and the desulfurization tower is provided with a high-efficiency demister 3, a multi-stage spray layer 4, and a slurry pool 7 sequentially from top to bottom; the spray layer 4 is provided with a nozzle 5 with the opening facing downward; The slurry pool 7 is connected to the spray layer 4 through a circulating spray pipeline with a slurry circulating pump 2; it is characterized in that the multi-stage spray layer 4 is arranged in one-to-one correspondence with the slurry circulating pump 2 outside the desulfurization tower; including Follow the steps below:

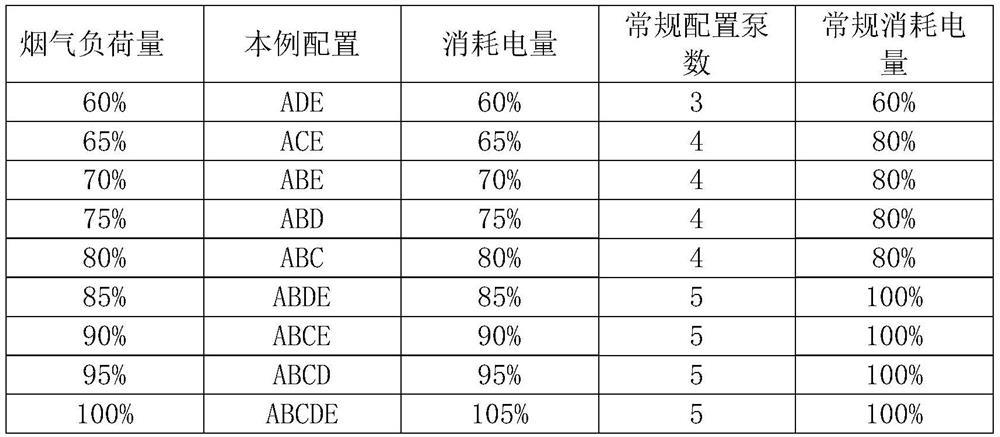

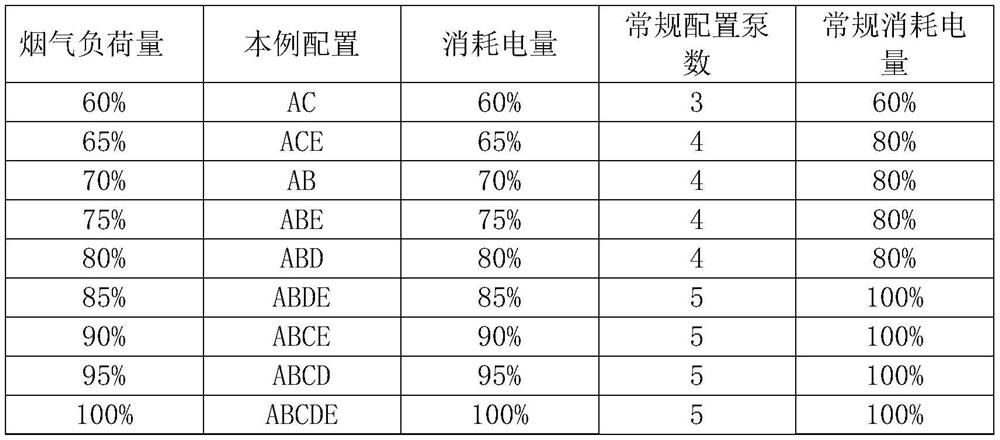

[0028] S1. According to the maximum amount of flue gas to be treated by desulfurization tower 1, that is, under 100% flue gas load, after calculating the total value of the slurry circulation flow required by desulfurization tower 1, the total va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com