Gating system with wall-mounted gating riser and working method thereof

A pouring system and wall-attaching technology, applied in manufacturing tools, metal processing equipment, casting and molding equipment, etc., can solve the problems of large space occupied by risers and runners, unfavorable process layout, low production efficiency, etc., and achieve production efficiency. Improve, prevent mixed bubbles, and ensure the effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

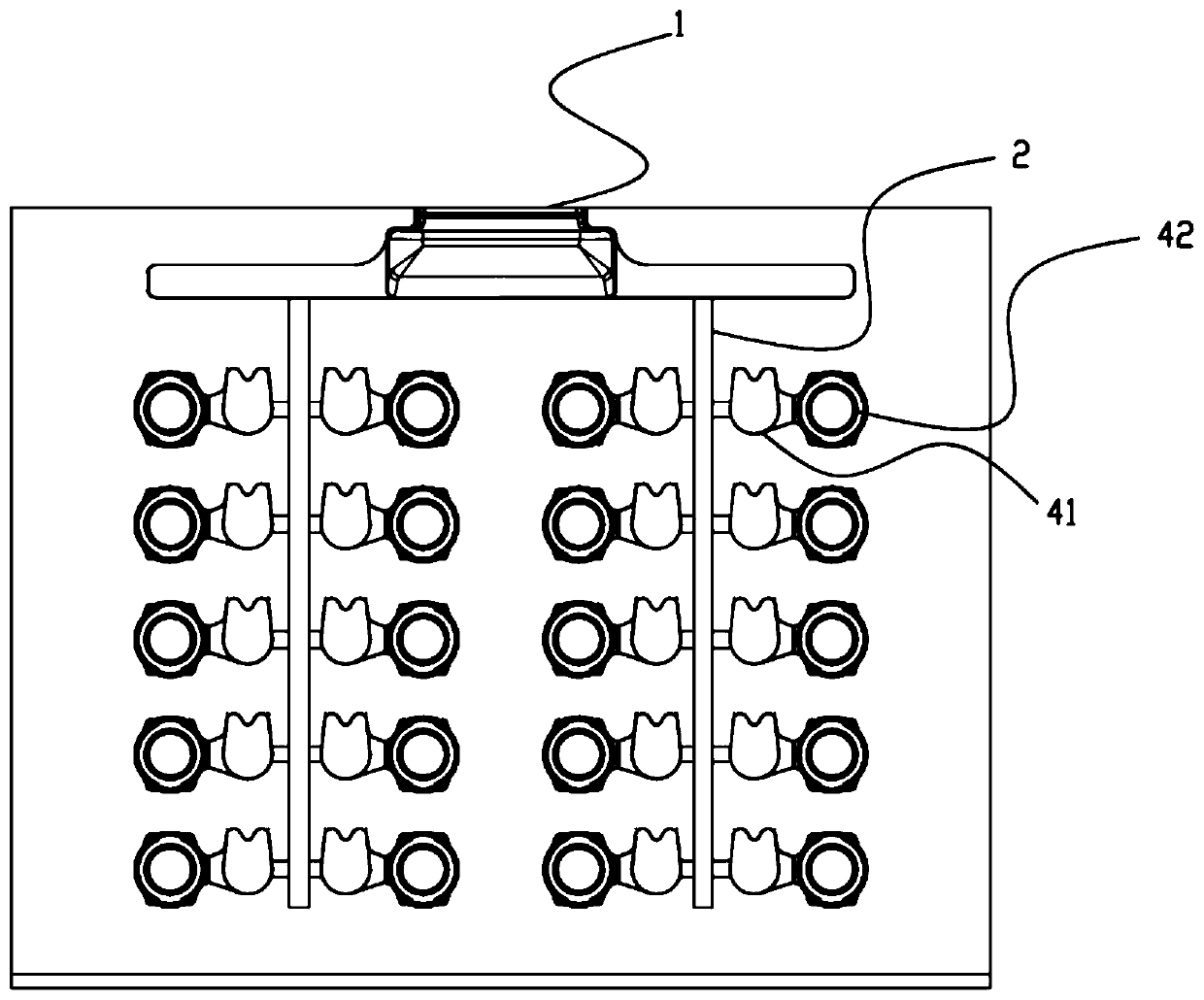

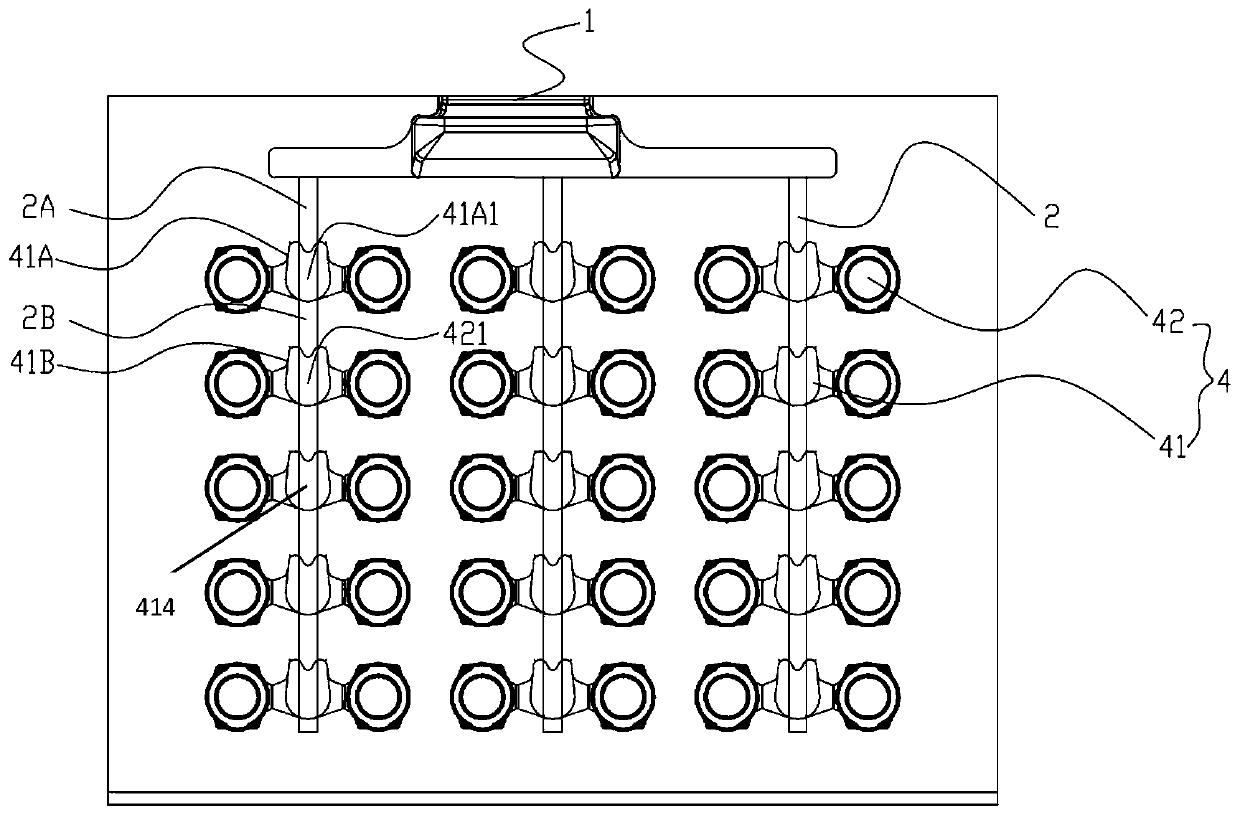

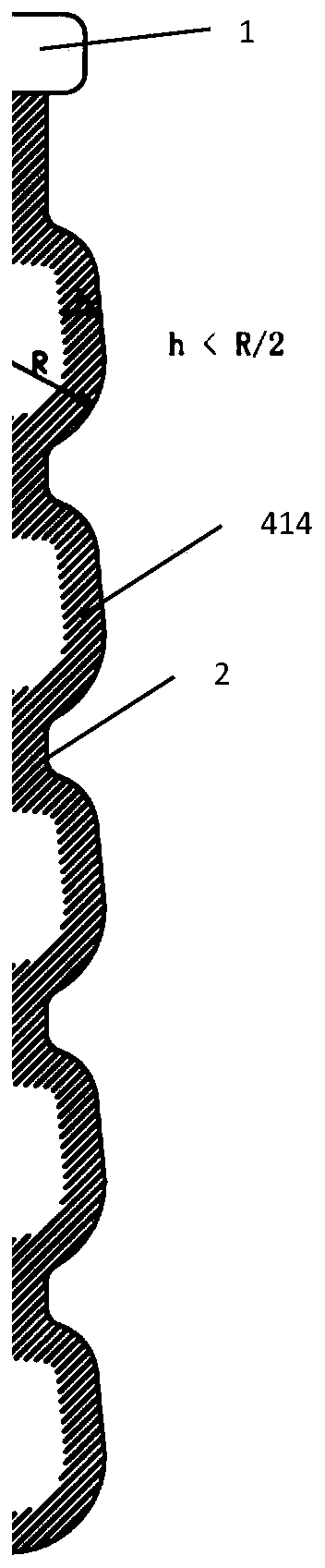

[0027] A gating system for a wall-attached sprue riser. The gating system includes a sprue 1 and a sprue 2. The sprue 2 is arranged in multiple rows at intervals. The upper end of the sprue 2 communicates with the sprue 1. Each row of sprue Multiple groups of pouring subsystems 4 are arranged on the road 2, and the pouring subsystems 4 are arranged vertically. The pouring subsystems are sand molds, and specifically include a product part 42 and a riser part 41. One riser part corresponds to two product parts. It is understood that the number of product departments can be set to a reasonable number according to the actual situation, and two product departments should not be understood as a limitation on the present application. The height of the central part of the riser part and the product part is roughly equal, the top of the riser part is higher than the top of the product part, and the side wall of the riser part 41 is provided with a side runner 414, and the side runner 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com