Power-on control protection system of fuel cell bus

A fuel cell system and fuel cell technology, applied in battery/fuel cell control devices, electrical transmission signal systems, electric vehicles, etc., can solve the problems of pre-charging circuits not working properly, vehicles not driving, and low fault tolerance rate, etc., to achieve Simple structure, no delay feedback, and the effect of improving the fault tolerance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

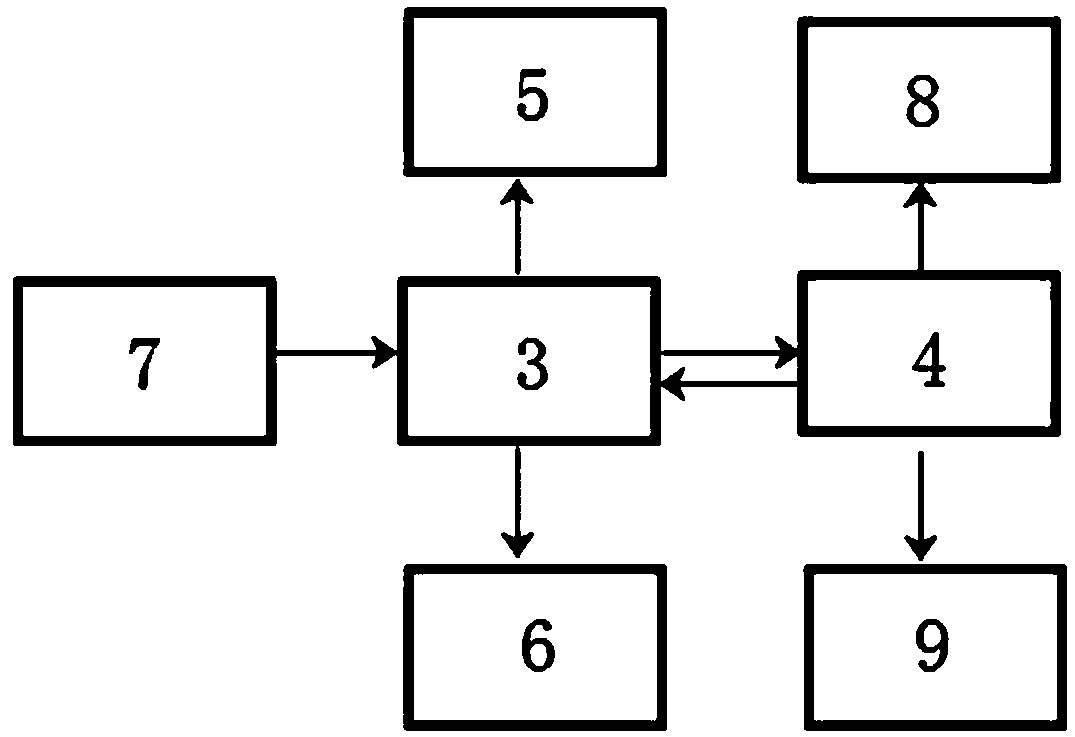

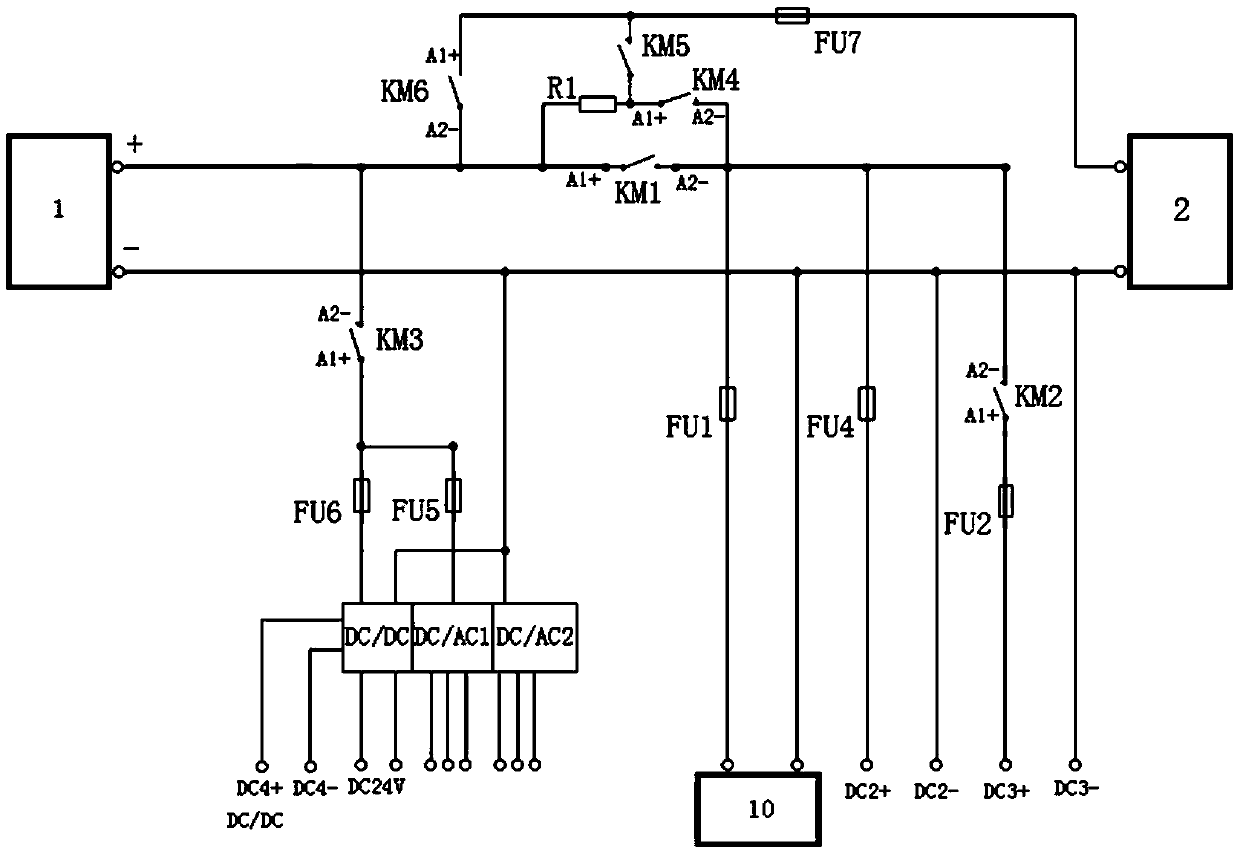

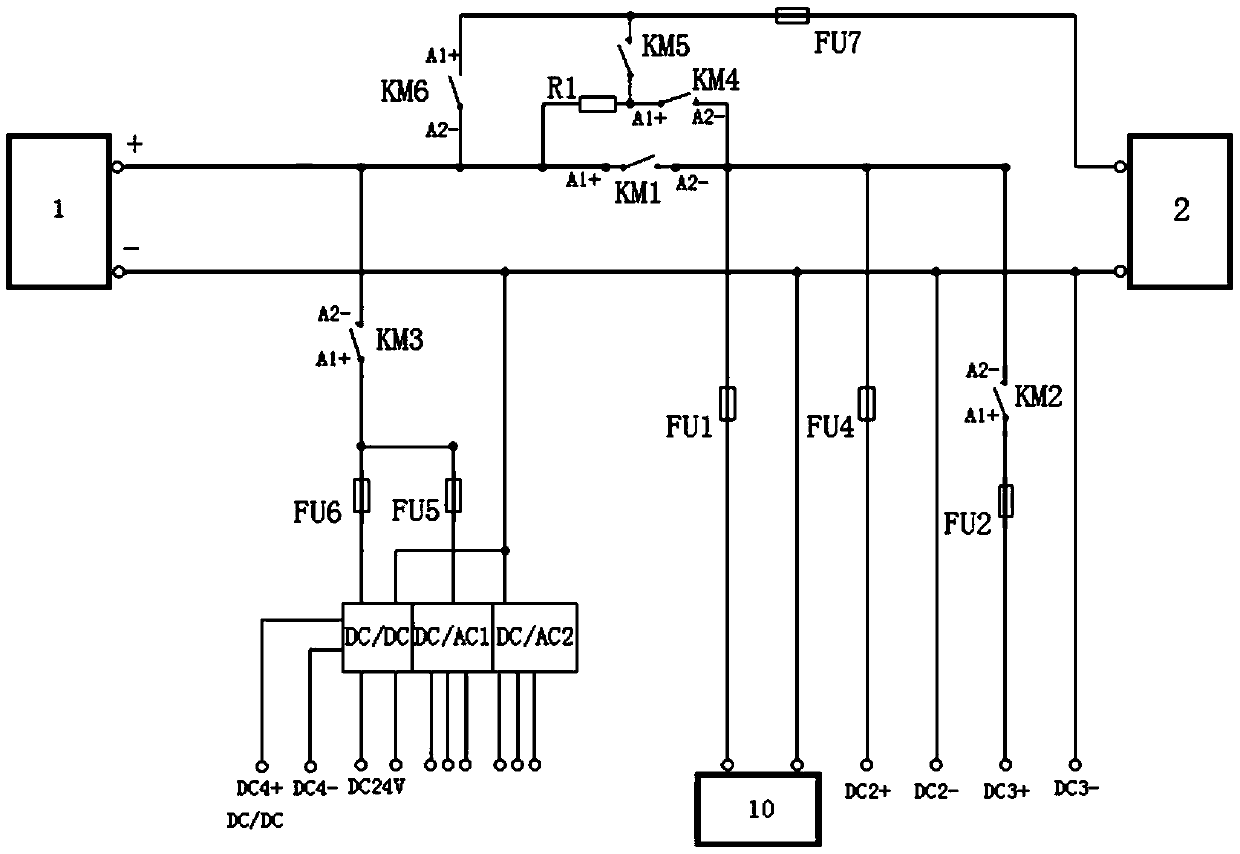

[0031] The invention relates to a power-on control and protection system of a fuel cell bus, which is used to avoid the problem that the whole vehicle cannot be driven and moved when the fuel cell system in the car fails, and to ensure that the high-voltage components of the whole vehicle and the fuel cell system cannot move when hydrogen gas leaks. Job security. Such as figure 1 As shown, the device includes a VCU (Vehicle control unit, vehicle control unit) 3, an FCU (Fuel-control unit, fuel cell control unit) 4, a pre-charging circuit 5, a high-voltage contactor 6, a hydrogen concentration sensor 7, and a display screen 8 and alarm9.

[0032] The hydrogen concentration sensor 7 is connected to the analog input terminal of the VCU3 through a hard wire, and is used to detect hydrogen leakage in the vehicle and prevent high voltage from being applied to the fuel cell system. The hydrogen concentration sensor 7 is provided with a hydrogen concentration probe. The hydrogen ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com