Lithium ion battery die cutting waste winding device

A lithium-ion battery and waste winding technology, which is applied in winding strips, thin material processing, transportation and packaging, etc., can solve the problems of adverse effects on battery performance and reduced workshop cleanliness, and achieve simple structure and low self-discharge rate, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

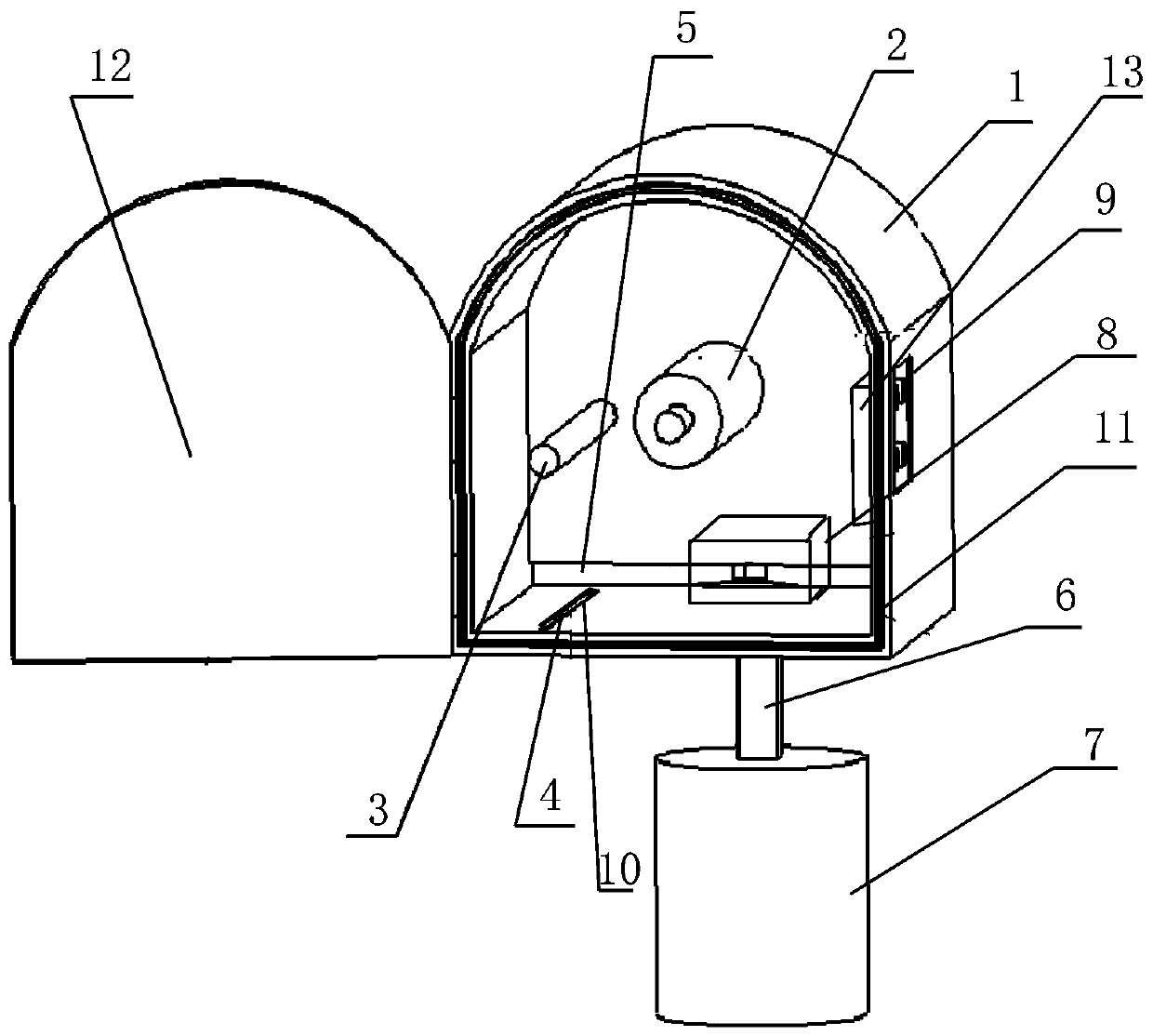

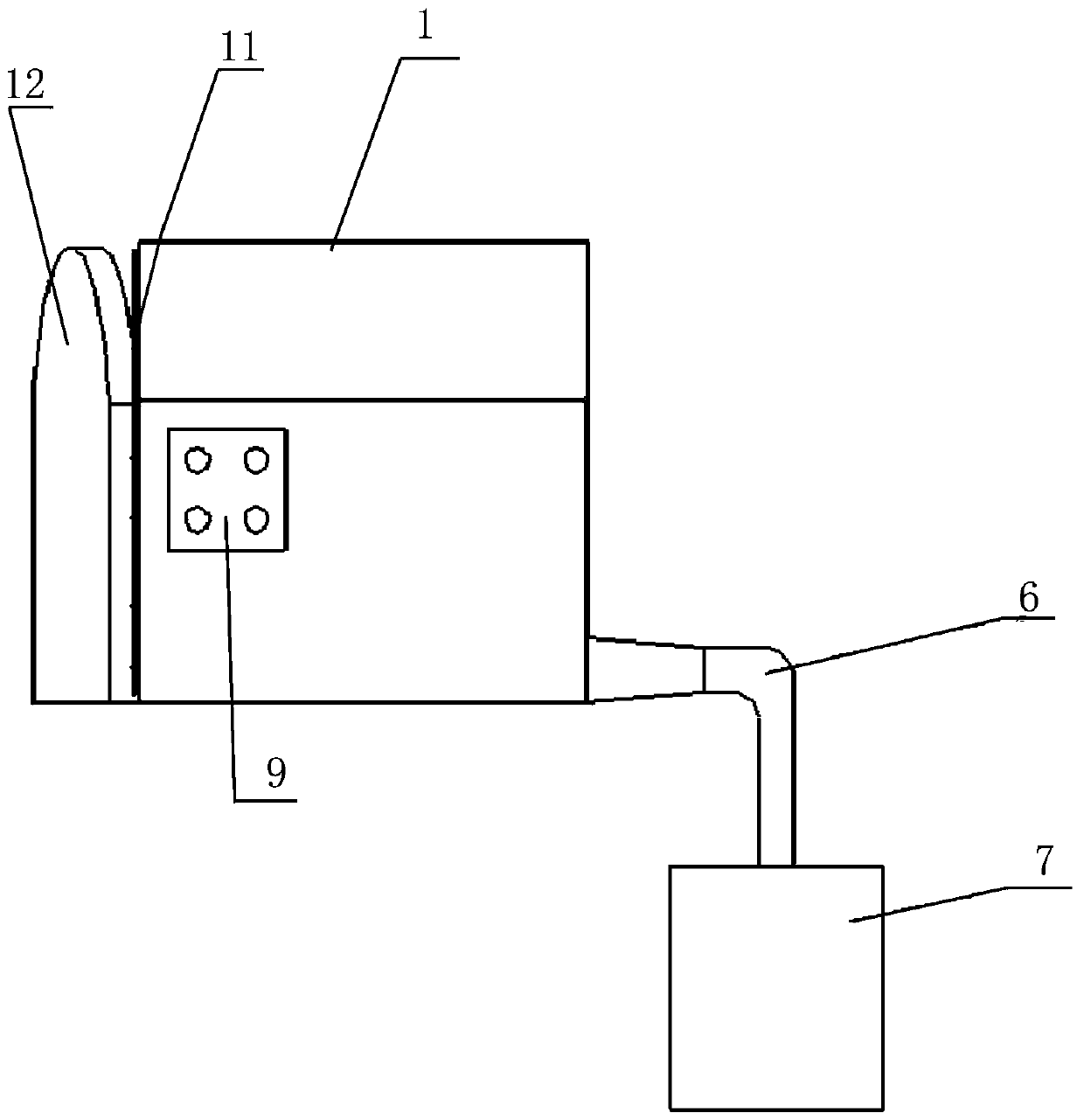

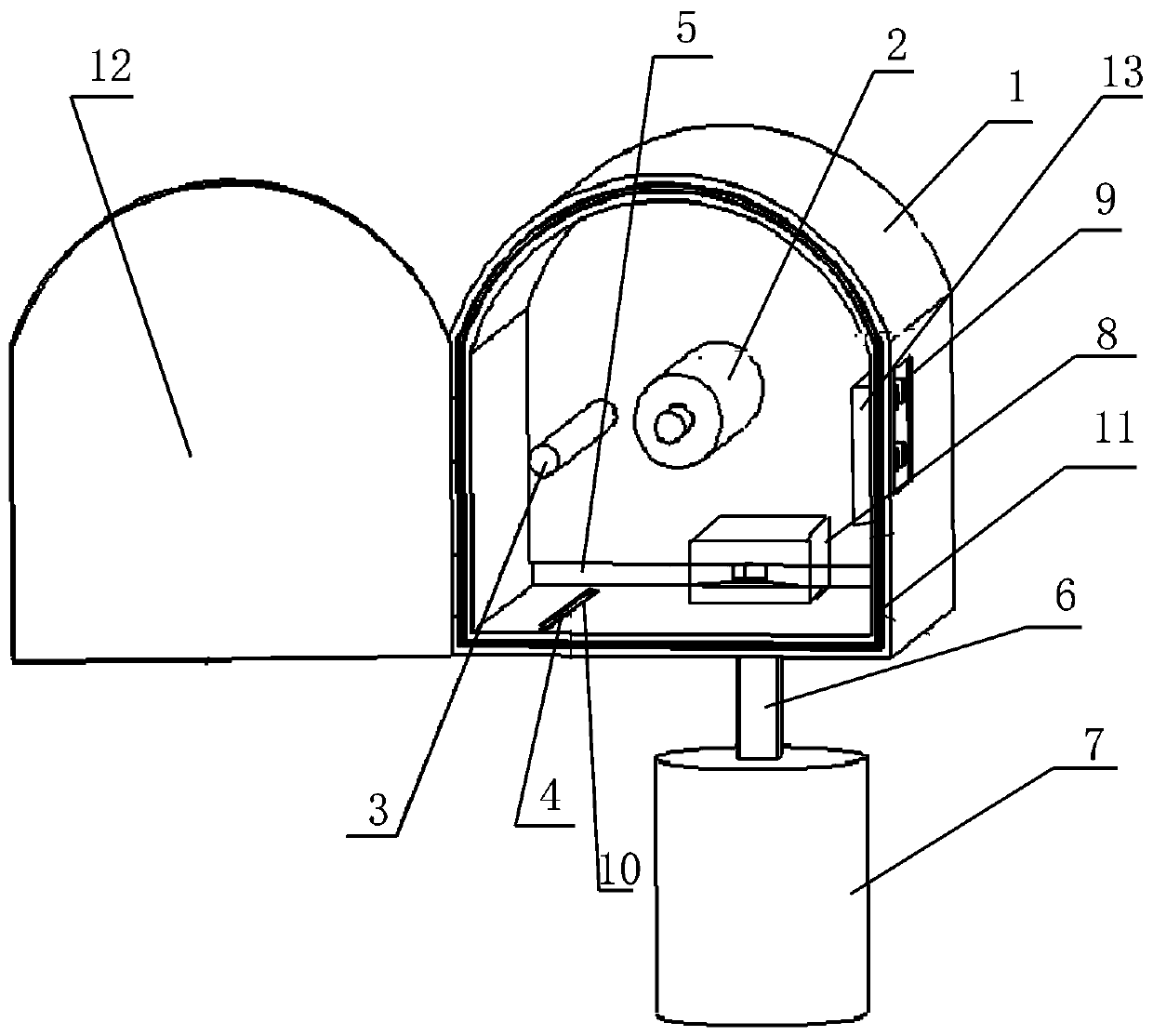

[0010] Embodiment one, in figure 1 and figure 2 Among them, the present invention provides a lithium-ion battery die-cut waste rewinding device, which mainly includes a box body 1, the box body 1 is placed on a workbench, and a box door 12 is provided at the front of the box body 1, The edge of the front part of the box body 1 is provided with a sealing ring 11. When the box door is closed, the sealing ring 11 closely fits the outer ring of the box door 12, so that the relative sealing of the box body 1 can be maintained during the operation of the vacuum system to prevent dust from leaking out. A rewinding shaft 2 is installed in the middle of the inner wall at the rear of the box body 1. Die-cutting waste is wound on the rewinding reel 2. A driving motor is connected to the rewinding reel 2. The driving end of the driving motor and the rewinding reel 2 is connected by transmission. The motor drives the winding shaft 2 to rotate, the winding shaft 2 is perpendicular to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com