Tungsten-doped vanadium dioxide film, and preparation method and application thereof

A vanadium dioxide and tungsten doping technology, used in ion implantation plating, coating, metal material coating process and other directions, can solve the problem of high phase transition temperature, achieve low phase transition temperature, short sputtering time, convenient The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

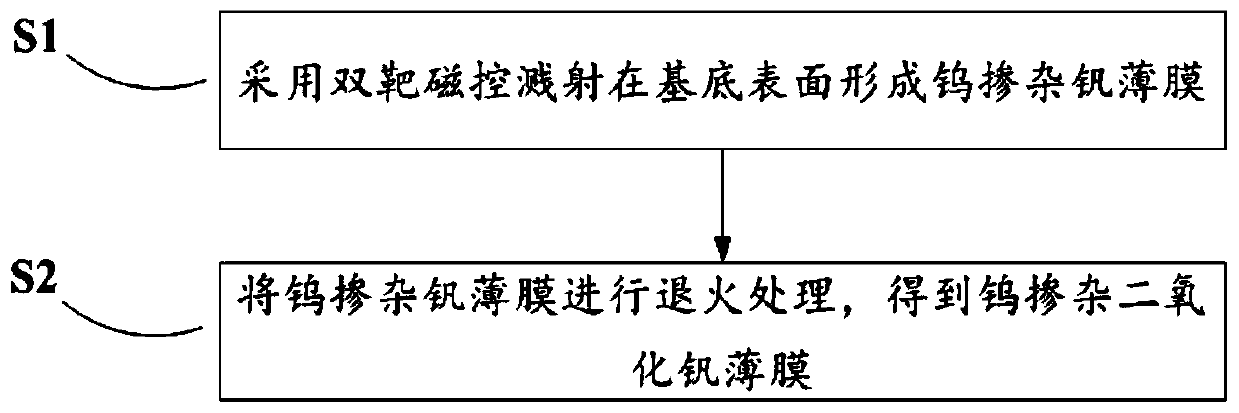

[0029] Two aspects of the present invention provide a method for preparing a tungsten-doped vanadium dioxide film, comprising the following steps:

[0030] S1: use double-target magnetron sputtering to form a tungsten-doped vanadium film on the surface of the substrate;

[0031] S2: annealing the tungsten-doped vanadium thin film to obtain a tungsten-doped vanadium dioxide thin film.

[0032] In the present invention, double-target magnetron sputtering is adopted, and compared with conventional single-target magnetron sputtering, tungsten atoms and vanadium atoms can be uniformly mixed before sputtering, and the composition uniformity of the obtained tungsten-doped vanadium dioxide film can be improved. , so that the annealed tungsten can be better doped in the room temperature lattice of vanadium dioxide, thereby greatly reducing the phase transition temperature.

[0033] Preferably, the substrate is one of FTO glass, quartz glass, sapphire or mica flakes.

[0034] Preferab...

Embodiment 1

[0046] (1) After cleaning the quartz glass to be plated with detergent, put it into distilled water for ultrasonic cleaning for 20 minutes, then put it into absolute ethanol for ultrasonic cleaning for 35 minutes, and finally put it into absolute ethanol to seal, and take it out to dry during use;

[0047] (2) Place the dried quartz glass substrate in a magnetron sputtering vacuum chamber, use vanadium and tungsten with a mass purity of 99.99% as targets, and pump the vacuum degree of the vacuum chamber to 2.9×10 -3After Pa, the temperature of the substrate was raised to 80°C, the flux of argon gas was controlled to be 200sccm and the working pressure of pre-sputtering was 0.5pa, and argon gas with a mass purity of 99.99% was used as the working gas for vanadium and tungsten targets. Carry out pre-sputtering, wherein, the power of vanadium target is 75W, the power of tungsten target is 10W, and the time of pre-sputtering is 15min; then the flux of argon gas is controlled to be ...

Embodiment 2

[0050] (1) After cleaning the quartz glass to be plated with detergent, put it into distilled water for ultrasonic cleaning for 25 minutes, then put it into absolute ethanol for ultrasonic cleaning for 40 minutes, and finally put it into absolute ethanol to seal, take it out and blow dry when using.

[0051] (2) Place the dried quartz glass substrate in a magnetron sputtering vacuum chamber, use vanadium and tungsten with a mass purity of 99.99% as the target, and pump the vacuum degree of the vacuum chamber to 2.9×10 -3 After Pa, the temperature of the substrate was raised to 80°C, the flux of argon gas was controlled to be 200sccm and the working pressure of pre-sputtering was 0.5pa, and argon gas with a mass purity of 99.99% was used as the working gas for vanadium and tungsten targets. Carry out pre-sputtering, wherein, the power of vanadium target is 75W, the power of tungsten target is 10W, and the time of pre-sputtering is 15min; then the flux of argon gas is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com