A kind of modification processing method of ferronickel slag aggregate

A treatment method, the technology of ferronickel slag, which is applied in the field of building materials, can solve the problems of high crushing value of ferronickel slag aggregate, accelerate cement, etc., and achieve the effects of reducing risk, accelerating hydration, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

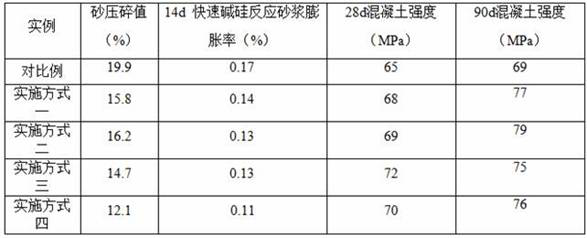

Examples

Embodiment 1

[0023] Modification method of nickel-iron slag aggregate, including the following steps:

[0024] 1) Sieves> 5mm nickel-iron slag aggregate;

[0025] 2) Pouring the nickel iron slag aggregate of the above screen to cement, sodium hydroxide, and water; wherein the ratio of the total mass of the cement and sodium hydroxide and the ratio of the nickel iron slag aggregate is 4: 1, The water ash is 0.4; where the amount of sodium hydroxide is 5% of cement quality;

[0026] 3) Step 2) The test block is evaporated at 80 ° C;

[0027] 4) Steam 24 h under the pressure of 1.5 MPa under pressure.

[0028] 5) Step 4) Try the block, screen, sieved, sieved, bonegite greater than 5 mm, used as concrete aggregate, and less than 5 mm component grinding to a specific surface area greater than 400m 2 / kg is used as concrete blend.

Embodiment 2

[0030] Modification method of nickel-iron slag aggregate, including the following steps:

[0031] 1) Sieves> 5mm nickel-iron slag aggregate;

[0032] 2) Pouring the nickel iron slag aggregate from the above-mentioned sieve with cement, sodium hydroxide, and water; wherein the ratio of the total mass of the cement and sodium hydroxide and the mass of the nickel iron residue aggregate is 2: 3. The water ash ratio is 0.6; where the amount of sodium hydroxide is 1% of cement quality;

[0033] 3) Step 2) The test block is evaporated at 80 ° C;

[0034] 4) Steam 24 h under the pressure of 1.5 MPa under pressure.

[0035] 5) Step 4) Try the block, screen, sieved, sieved, bonegite greater than 5 mm, used as concrete aggregate, and less than 5 mm component grinding to a specific surface area greater than 400m 2 / kg is used as concrete blend.

Embodiment 3

[0037] Modification method of nickel-iron slag aggregate, including the following steps:

[0038] 1) Sieves> 5mm nickel-iron slag aggregate;

[0039] 2) Pouring the nickel iron slag aggregate of the above screen to cement, sodium hydroxide, potassium hydroxide, and water; in which cement and sodium hydroxide and total quality of potassium hydroxide are nickel with nickel The ratio of mass is 2: 3, the water as average ratio is 0.5; wherein the amount of sodium hydroxide and potassium hydroxide is 5% of cement quality, sodium hydroxide and potassium hydroxide is 3: 2;

[0040] 3) Step 2) The test block is evaporated at 80 ° C;

[0041] 4) Steam 12h under pressure of 3.0 MPa in pressure of 3.0 MPa;

[0042] 5) Step 4) Try the block, screen, sieved, sieved, bonegite greater than 5 mm, used as concrete aggregate, and less than 5 mm component grinding to a specific surface area greater than 400m 2 / kg is used as concrete blend.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com