A benzene-free multi-component dehydrating agent for esterification reaction

A technology of esterification reaction and dehydrating agent, applied in the field of chemistry, can solve the problems of high toxicity of benzene compounds to human body, and achieve the effect of low toxicity and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

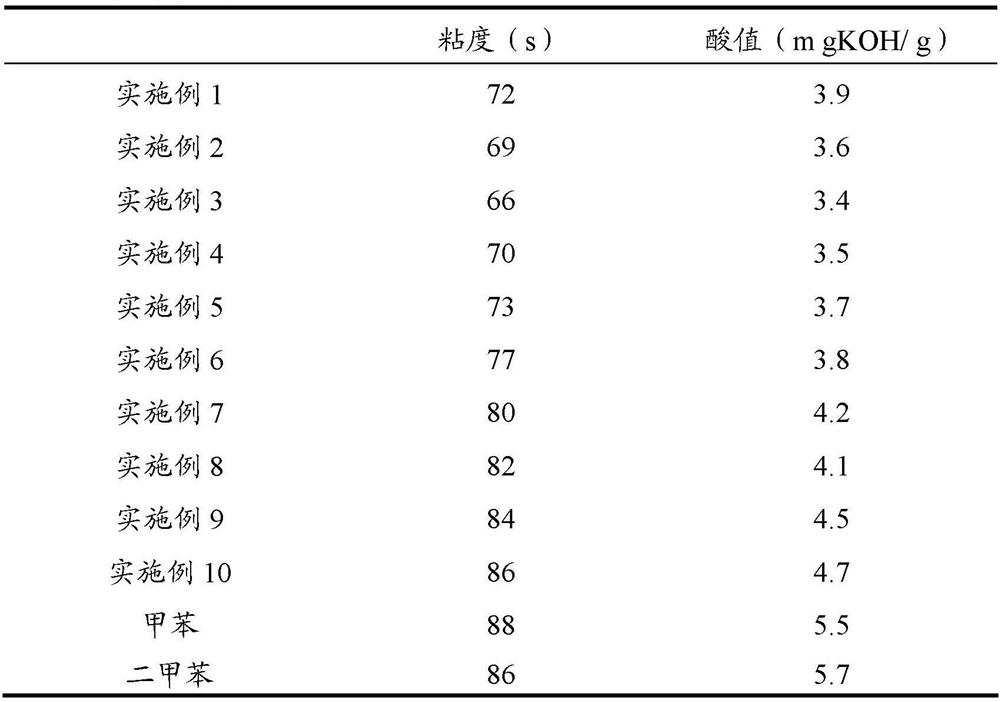

Examples

Embodiment 1

[0017] A benzene-free multi-component dehydrating agent for esterification, specifically taking 8.6g of n-valeraldehyde, 31.6g of n-pentyl ether and 11.6g of n-butyl acetate, and mixing them uniformly.

[0018] The reactants are soybean oil fatty acid, phthalic anhydride and glycerin, the alkyd functional ratio is set at 1.2:1, respectively 100g, 148g and 92g, and the mass ratio of dehydrating agent to reactant is 0.1:1.

[0019] Put soybean oil fatty acid, glycerin, phthalic anhydride, and dehydrating agent into the reaction kettle, and pass CO 2 , heat up to reflux, raise the temperature from 160°C to 180°C at a rate of 10°C / h, and then raise the temperature to 220°C at a rate of 20°C / h to keep warm and reflux until the resin viscosity and acid value reach the specified end point indicators, then cool down, Diluted.

Embodiment 2

[0021] A benzene-free multi-component dehydrating agent for esterification, specifically taking 8.6g of n-valeraldehyde, 47.5g of n-pentyl ether and 11.6g of n-butyl acetate, and mixing them uniformly.

[0022] The reactants are soybean oil fatty acid, phthalic anhydride and glycerin, the alkyd functional ratio is set at 1.2:1, respectively 100g, 148g and 92g, and the mass ratio of dehydrating agent to reactant is 0.1:1.

[0023] Put soybean oil fatty acid, glycerin, phthalic anhydride, and dehydrating agent into the reaction kettle, and pass CO 2 , heat up to reflux, raise the temperature from 160°C to 180°C at a rate of 10°C / h, and then raise the temperature to 220°C at a rate of 20°C / h to keep warm and reflux until the resin viscosity and acid value reach the specified end point indicators, then cool down, Diluted.

Embodiment 3

[0025] A benzene-free multi-component dehydrating agent for esterification, specifically taking 8.6g of n-valeraldehyde, 31.6g of n-pentyl ether and 23.2g of n-butyl acetate, and mixing them uniformly.

[0026] The reactants are soybean oil fatty acid, phthalic anhydride and glycerin, the alkyd functional ratio is set at 1.2:1, respectively 100g, 148g and 92g, and the mass ratio of dehydrating agent to reactant is 0.1:1.

[0027] Put soybean oil fatty acid, glycerin, phthalic anhydride, and dehydrating agent into the reaction kettle, and pass CO 2 , heat up to reflux, raise the temperature from 160°C to 180°C at a rate of 10°C / h, and then raise the temperature to 220°C at a rate of 20°C / h to keep warm and reflux until the resin viscosity and acid value reach the specified end point indicators, then cool down, Diluted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com