Ceramic coating

A technology of coatings and ceramics, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of impact resistance and high temperature, poor adhesion, high toxicity, etc., and achieve the effects of low toxicity, fast drying speed, and excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] The preparation method of described coating for ceramics, comprises the following steps:

[0087] S1: Polyester resin, rosin resin, acrylic resin, maleic anhydride, polybutene wax, talcum powder, bentonite, titanium dioxide, boron carbide, polyester fiber, boron fiber, hydroxypropyl methylcellulose, ceramics Fibers, surfactants, degassing agents, leveling agents, dispersants, wetting agents, adhesion promoters, catalysts, and initiators are mixed at a microwave power of 140-180W, a temperature of 92-96°C, and a rotation speed of 2000 Stirring at -2600r / min for 3-3.5h to prepare mixture a;

[0088] S2: Add tert-dodecylmercaptan, benzoin ethyl ether, acrylic acid emulsion, glutamine solution, drooping agent, toughening agent, brightening agent, defoamer, tackifier to the mixture a prepared in step S1, Stirring for 3.2-4.8h at a microwave power of 120-160W, a temperature of 118-126°C, and a rotation speed of 400-600r / min, to obtain a mixture b;

[0089] S3: Add curing ag...

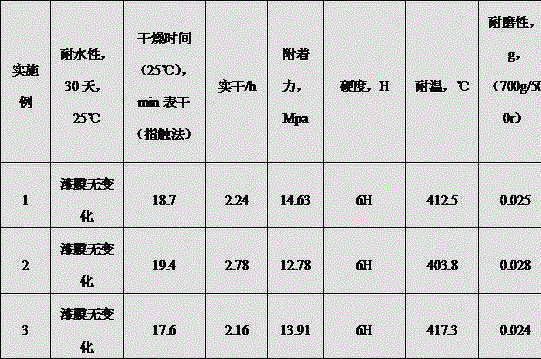

Embodiment 1

[0109] A coating for ceramics, which comprises the following raw materials in units of weight: 150 parts of polyester resin, 58 parts of rosin resin, 38 parts of acrylic resin, 25 parts of maleic anhydride, 20 parts of tert-dodecyl mercaptan, benzoin 16 parts of ether, 35 parts of acrylic emulsion, 25 parts of glutamine solution, 35 parts of polybutene wax, 8 parts of talcum powder, 6 parts of bentonite, 5 parts of titanium dioxide, 4 parts of boron carbide, 5 parts of polyester fiber, 3 parts of boron fiber 6 parts, 6 parts of hydroxypropyl methylcellulose, 3 parts of ceramic fiber, 0.6 parts of surfactant, 0.5 parts of degassing agent, 0.6 parts of leveling agent, 0.7 parts of dispersing agent, 0.4 parts of wetting agent, adhesion promoter 0.3 parts, 0.1 parts of catalyst, 0.2 parts of initiator, 0.5 parts of weeping agent, 0.4 parts of toughening agent, 0.4 parts of brightening agent, 0.5 parts of defoamer, 0.4 parts of tackifier, 1.5 parts of curing agent, 0.3 parts of pres...

Embodiment 2

[0157]A coating for ceramics, with weight as unit, comprising the following raw materials: 135 parts of polyester resin, 52 parts of rosin resin, 32 parts of acrylic resin, 18 parts of maleic anhydride, 16 parts of tertiary dodecyl mercaptan, benzoin 12 parts of ether, 30 parts of acrylic emulsion, 20 parts of glutamine solution, 22 parts of polybutene wax, 6 parts of talcum powder, 4 parts of bentonite, 3 parts of titanium dioxide, 3 parts of boron carbide, 4 parts of polyester fiber, 3 parts of boron fiber 4 parts, 4 parts of hydroxypropyl methylcellulose, 2 parts of ceramic fiber, 0.5 parts of surfactant, 0.3 parts of degassing agent, 0.3 parts of leveling agent, 0.5 parts of dispersing agent, 0.3 parts of wetting agent, adhesion promoter 0.2 parts, catalyst 0.1 parts, initiator 0.2 parts, draping agent 0.4 parts, toughening agent 0.3 parts, brightener 0.3 parts, defoamer 0.3 parts, tackifier 0.3 parts, curing agent 0.9 parts, preservative 0.2 parts , 0.2 parts of antioxida...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com