Vinasse spreading and airing machine

A distiller's lees booth and distiller's grains booth technology, which is applied in the field of drying machines, can solve the problems of not being able to ensure the uniformity of distiller's grains spreading, affecting the uniform mixing of distiller's grains and distiller's grains, and requiring high sanitation on the ground for spreading distiller's grains, and achieving high drying efficiency of distiller's grains. Simple, even lees spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

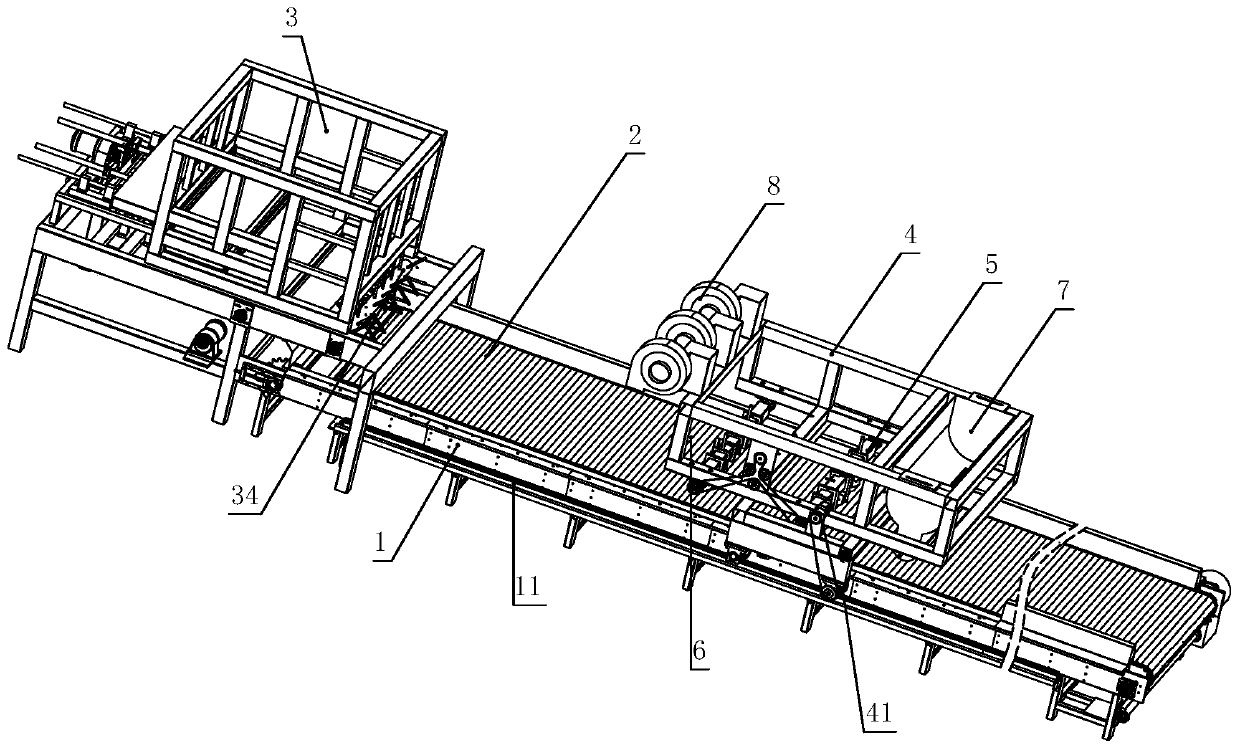

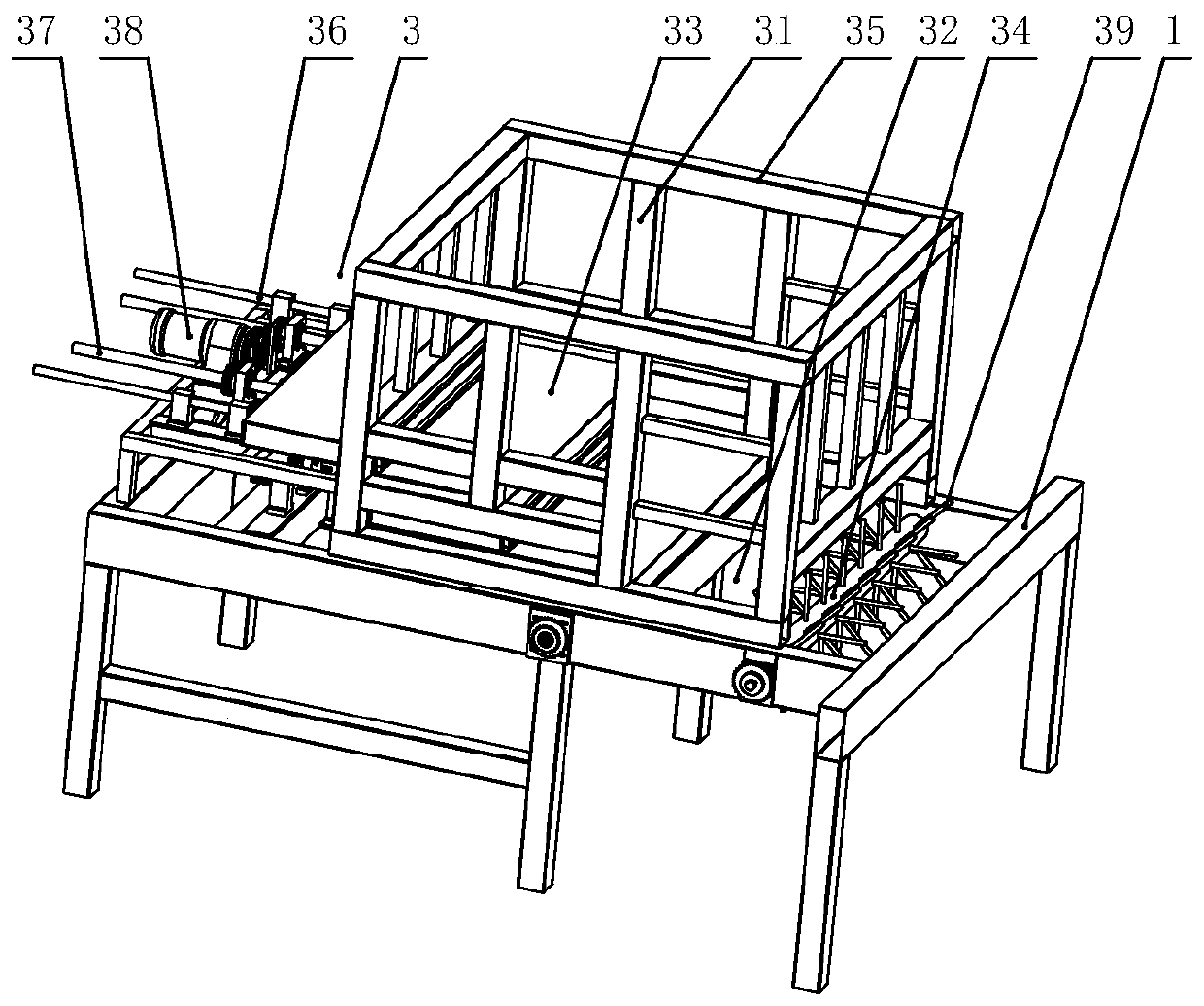

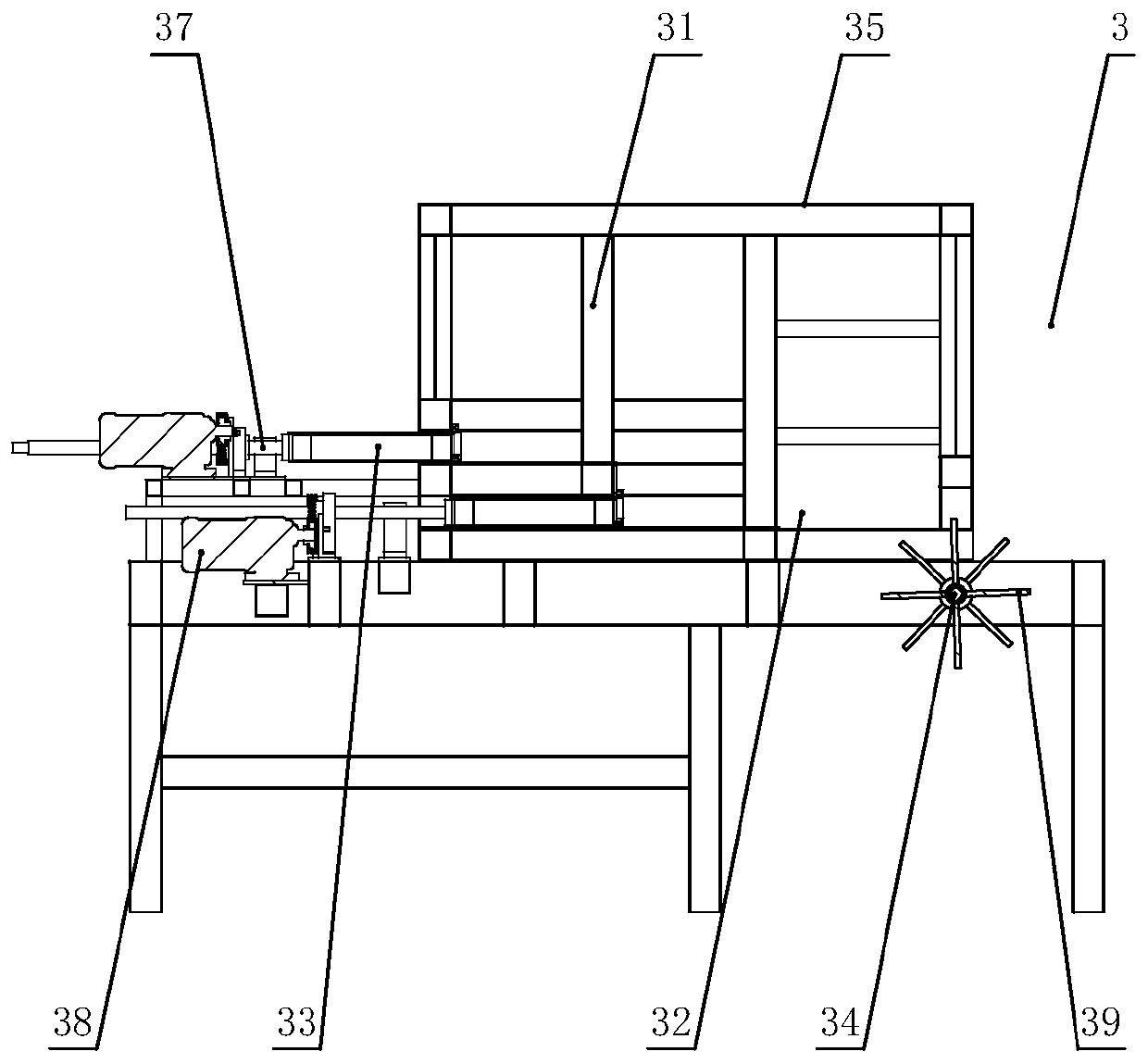

[0033] Such as figure 1 with 4 The shown distiller’s lees spreading machine includes a main frame 1, the main frame 1 is provided with a conveyor chain plate 2 conveyed on the main frame 1, and the conveyor chain plate 2 is formed by splicing a plurality of stainless steel chain plates , Has the advantages of long service life, corrosion resistance, easy cleaning, etc.; the main frame 1 is provided with a feeding device 3 at one end of the conveyor chain plate 2; A movable frame 4 that moves back and forth on the upper side of the conveyor chain plate 2. The main frame 1 is provided with slideways 11 on both sides of the conveyor chain plate 2, and pulleys 41 are provided on both sides of the movable frame 4 opposite to the slideways 11. The moving frame 4 is also provided with a moving motor for driving the pulley 41 to slide in the chute 11, which can ensure that the conveying chain plate 2 is repeatedly stirred for the distiller's grains in the plow, thereby improving the dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com