Coupled modular fabricated steel structure building

A prefabricated, steel structure technology, applied in the direction of building construction, residential construction, construction, etc., can solve the problems of repeated waste of structural components, difficult connection, complex force transmission, etc., to save labor, avoid welding operations, and ensure the overall sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

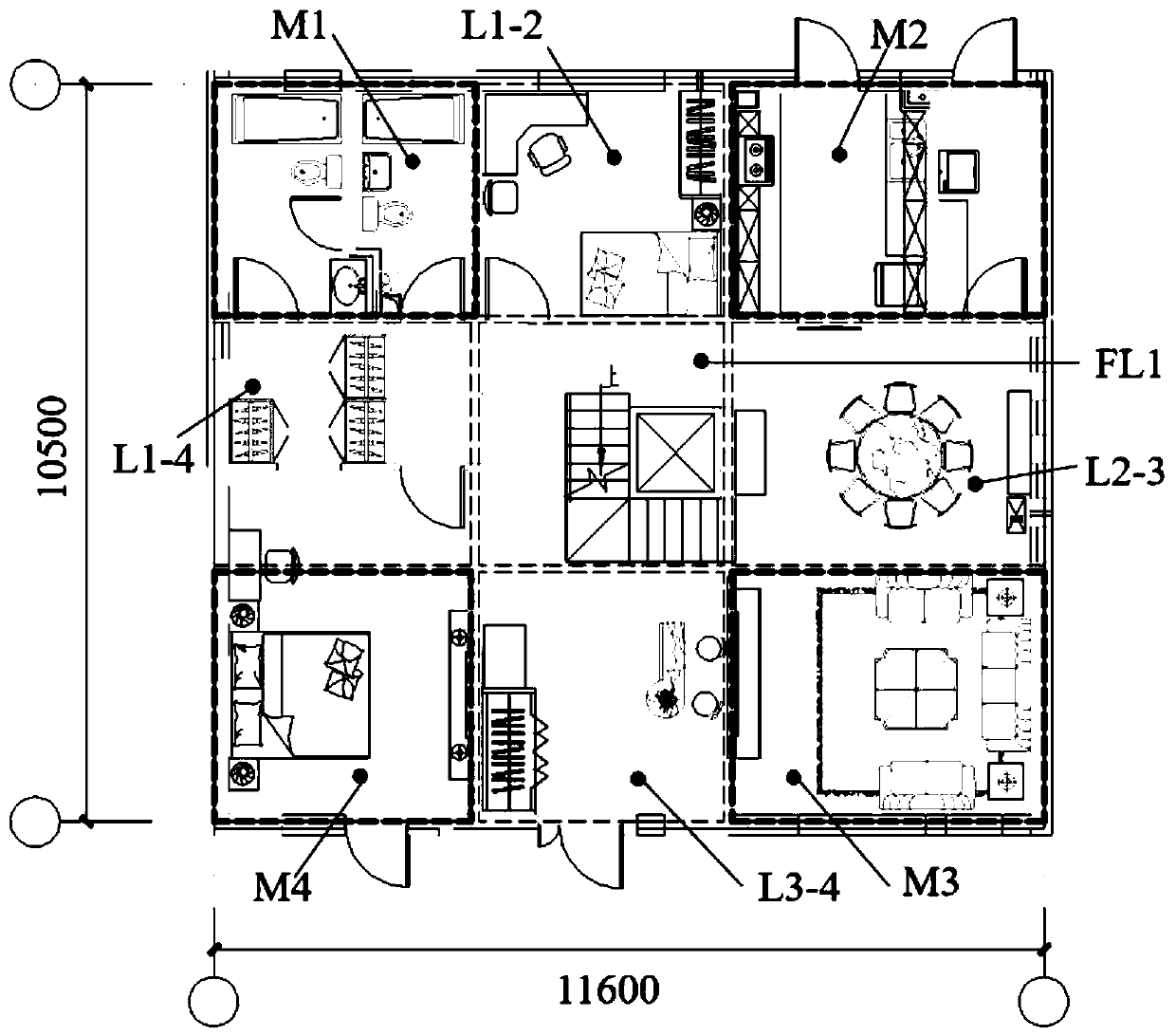

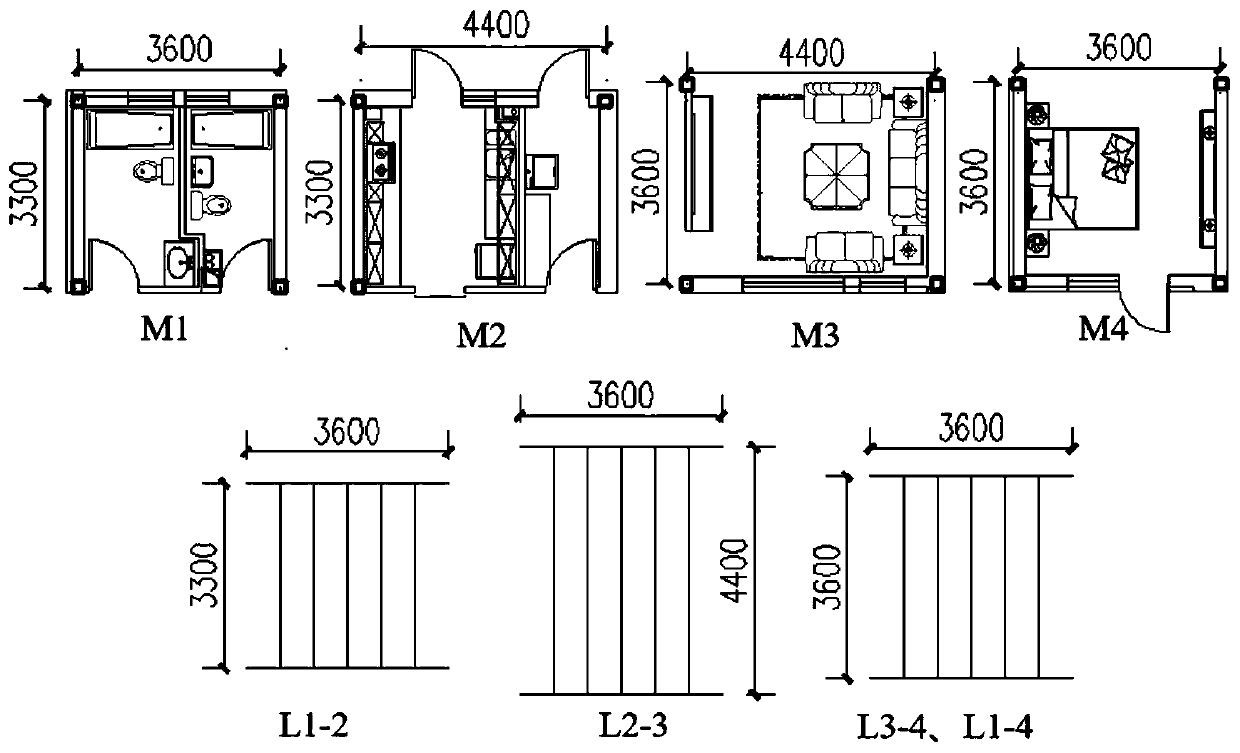

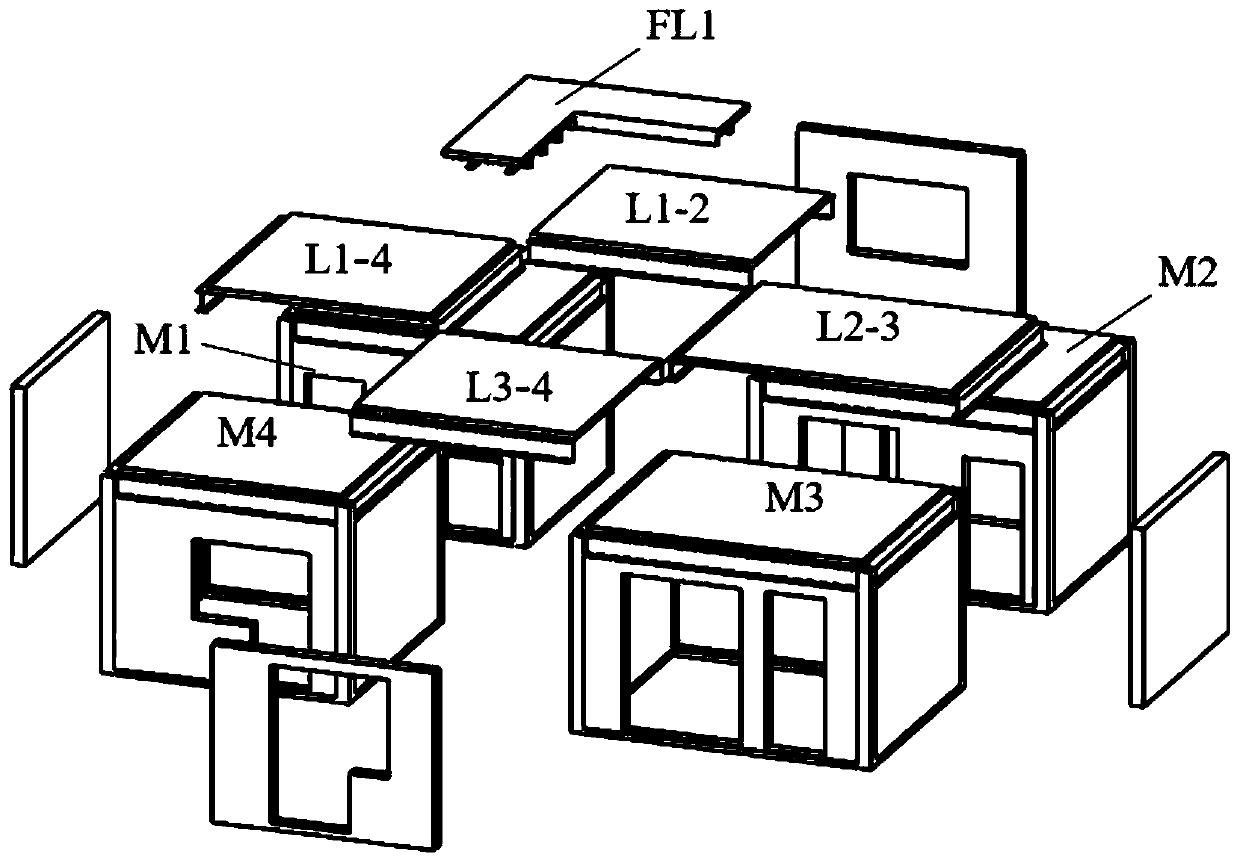

[0045] Now take a residential building whose outer axis dimension is 11.6m×10.5m as an example ( figure 1 ), detailing the method and process of assembling a modular prefabricated steel structure house with joint limbs, the specific steps are as follows:

[0046] 1. Arrangement of integrated room module units

[0047] To avoid situation SII 2 With the emergence of situation SⅢ, considering the limitation that the width of the integrated room module unit is less than 3.6m, the building plane is divided into a combination of several rectangular blocks by rooms or specific building functional areas. The division results are shown in figure 1 . Arrange integrated room module units according to the aforementioned methods and principles, figure 1 The position of the bold dotted frame shown is the integrated room module unit, where M1 is the bathroom module, M2 is the kitchen module, M3 is the living room module, and M4 is the bedroom module.

[0048] 2. Arrange the combined limb...

Embodiment 2

[0055] Now take a residential building whose outer axis dimension is 11.0m×10.5m as an example ( Figure 5 ), detailing the method and process of assembling a modular prefabricated steel structure house with joint limbs, the specific steps are as follows:

[0056] 1. Arrangement of integrated room module units

[0057] To avoid situation SII 2 With the emergence of situation SⅢ, considering the limitation that the width of the integrated room module unit is less than 3.6m, the building plane is divided into a combination of several rectangular blocks by rooms or specific building functional areas. The division results are shown in Figure 5 . Arrange integrated room module units according to the aforementioned methods and principles, Figure 5 The position of the bold dotted line box shown is the integrated room module unit, where M1 is the secondary bedroom module, M2 is the integrated kitchen and bathroom module, M3 is the living room module, and M4 is the main bedroom mo...

Embodiment 3

[0065] Now take a residential building whose outer axis dimension is 12.4m×9.3m as an example ( Figure 9 ), detailing the method and process of assembling a modular prefabricated steel structure house with joint limbs, the specific steps are as follows:

[0066] 1. Arrangement of integrated room module units

[0067] To avoid situation SII 2 With the emergence of situation SⅢ, considering the limitation that the width of the integrated room module unit is less than 3.6m, the building plane is divided into a combination of several rectangular blocks by rooms or specific building functional areas. The division results are shown in Figure 9 . Arrange integrated room module units according to the aforementioned methods and principles, Figure 9 The position of the bold dotted line box shown is the integrated room module unit, where M1, M2, M3, and M4 are bedroom module 1, bedroom module 2, bedroom module 3, and bedroom module 4, respectively.

[0068] 2. Arrange the combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com