Cooling fan, air cooling system and engine

A cooling fan and air-cooling system technology, which is applied in the direction of engine components, engine cooling, machine/engine, etc., can solve the problems of reduced transmission efficiency, large wind resistance of blades on the windward side, and low efficiency of cooling blades, so as to optimize air volume, The effect of reducing wind resistance and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

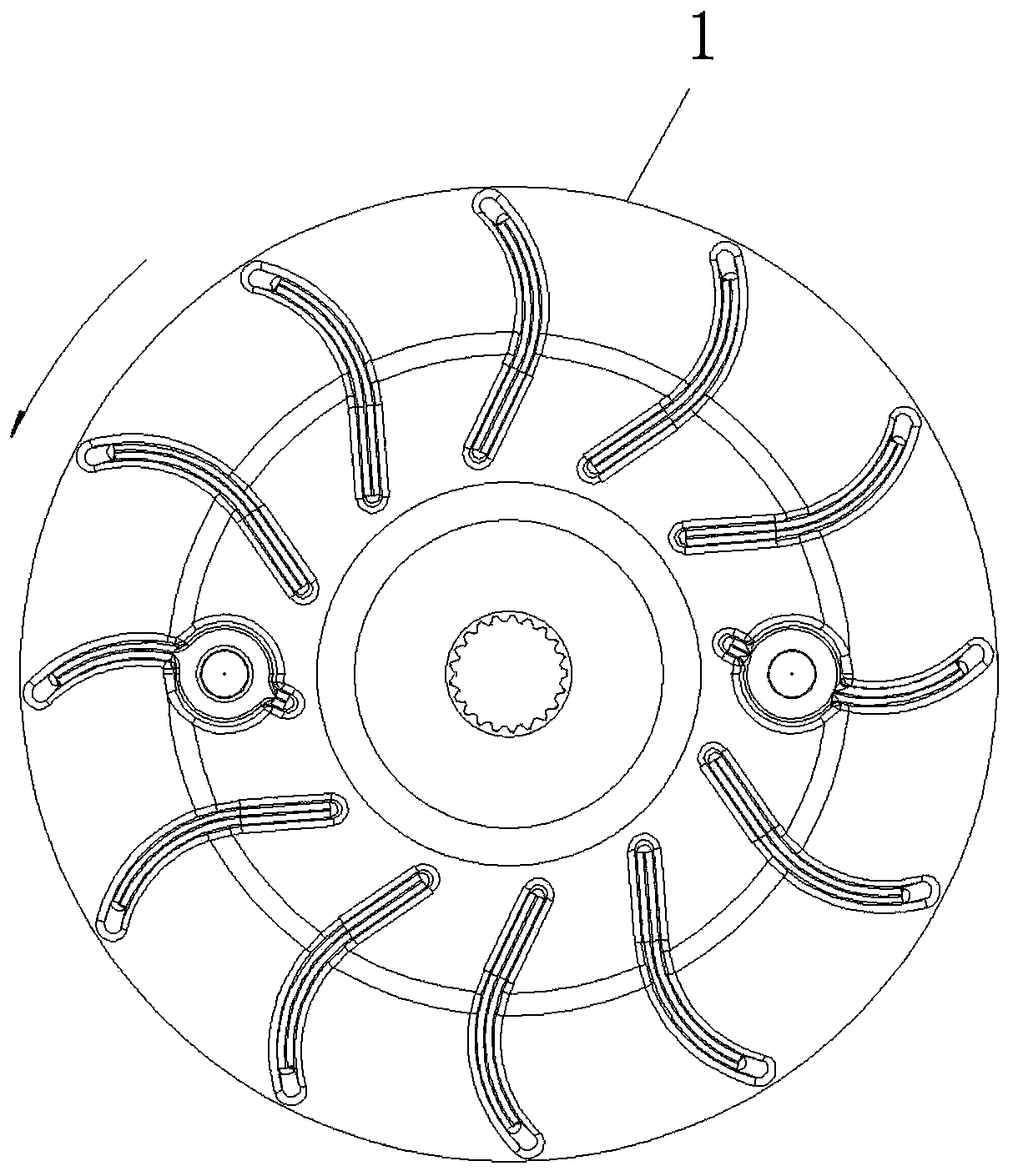

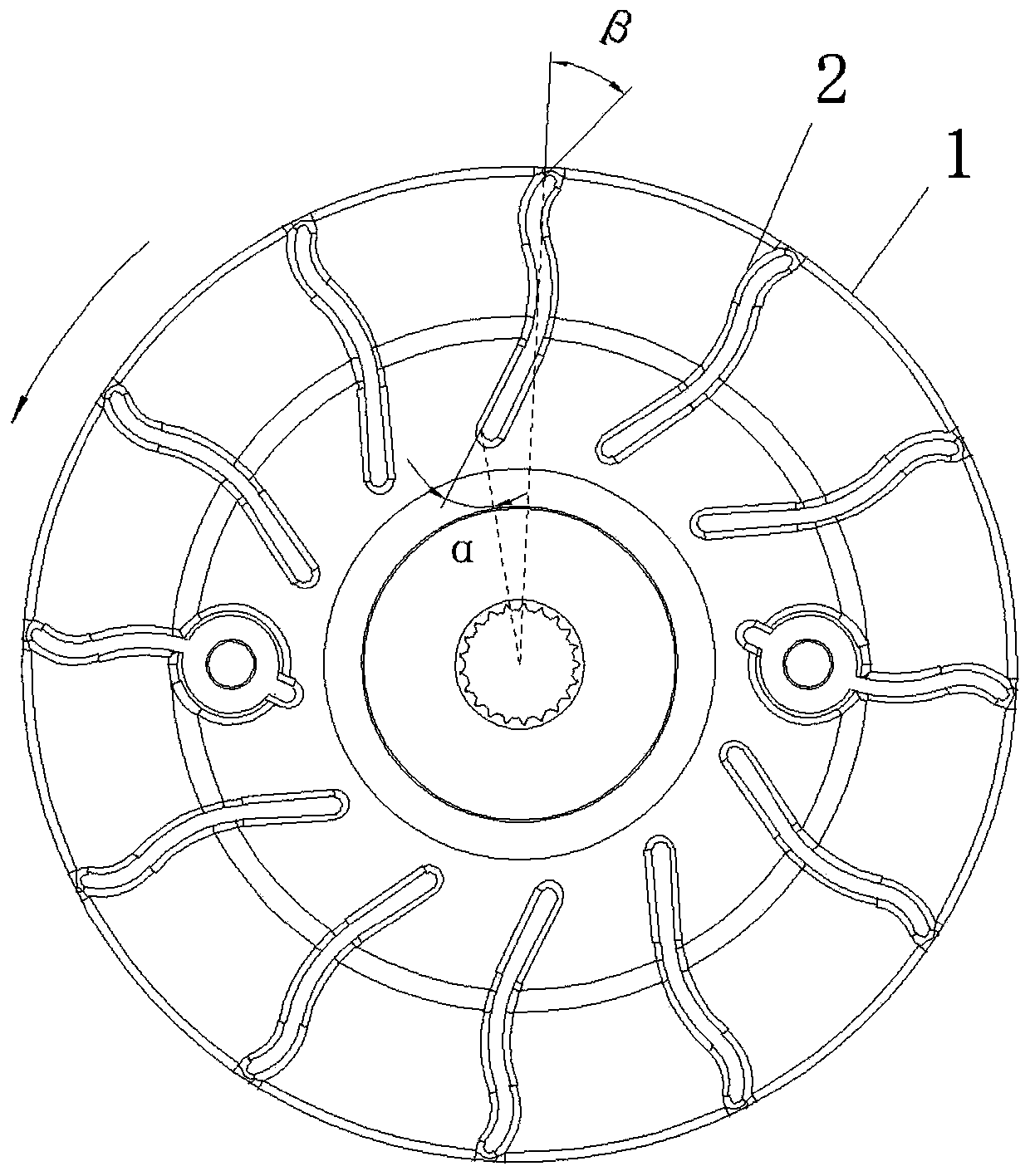

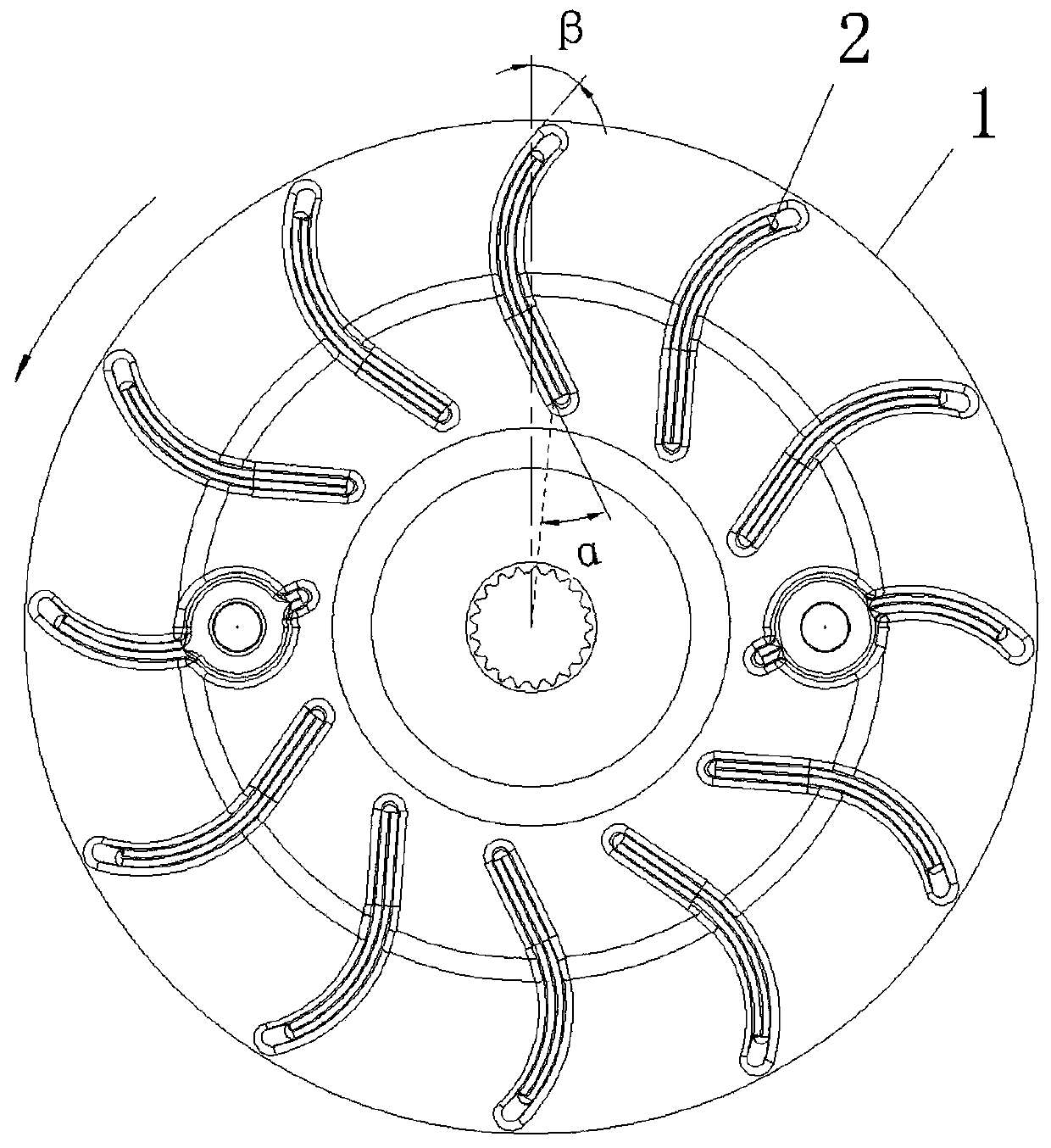

[0025] figure 1 It is a schematic diagram of the existing cooling fan structure; figure 2 Schematic diagram of the structure of the cooling fan of the present invention figure 1 ; image 3 Schematic diagram of the structure of the cooling fan of the present invention figure 2 ; Figure 4 for image 3 Schematic diagram of the side view structure; Figure 5 A schematic diagram of the structure of the engine case cover; Figure 6 A schematic diagram of the engine structure;

[0026] combine figure 1 As shown, the tail of the blade of the existing engine or reducer cooling fan is bent to the direction of rotation. When the head of the air flow blade flows to the tail, the wind flow has a radial outward flow trend based on centrifugal force, but the curved tail structure has a negative impact on the wind flow. The resistance makes the air flow have radial inward resistance. This structure makes the wind resistance caused by the blades to the air flow larger, resulting in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com