Process for manufacturing magnesium alloy wheel

A manufacturing process, magnesium alloy technology, applied in the field of magnesium alloy wheel manufacturing process, to achieve the effect of reducing fuel consumption, safe and convenient operation, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

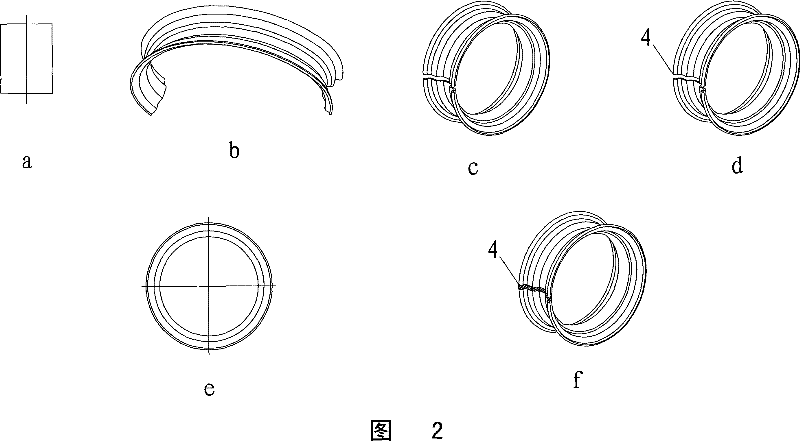

[0030] The wheel rim manufacturing process of the present invention mainly includes: a hot extrusion step, a rounding step and a pore processing step.

[0031] In the hot extrusion step, the magnesium alloy bar is first cut to a fixed length, refer to a of FIG. 2 . Then in a set of hot extrusion dies (section forming device), the magnesium alloy bar is extruded into a rim semi-finished product. Specifically, the magnesium alloy bar is hot extruded into a profile with a predetermined section, and then in a longitudinal forming device such as A large half of the elliptical rim as shown in b of Figure 2 is formed on the arc track. The elliptical rim here mainly refers to a shape close to an ellipse or an elliptical rim. For example, the two ends of the semi-finished rim shown in b of Figure 2 are in The rim is rolled on a small circle track, and the middle is rolled on a large circle track, or the semi-finished rim is directly bent on an elliptical track. The aforementioned larg...

no. 2 example

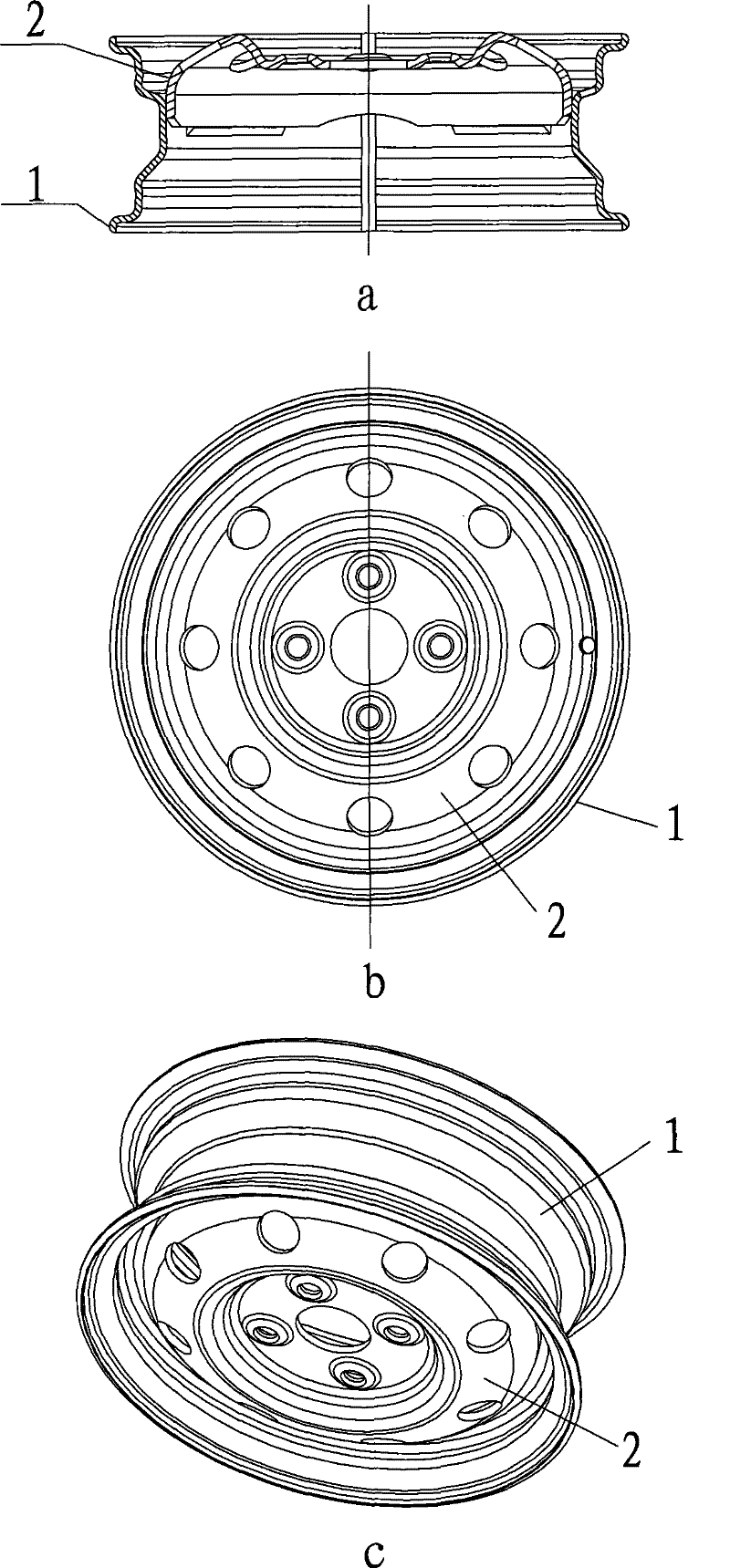

[0035]The magnesium alloy wheel manufacturing process of the present invention mainly includes a wheel rim manufacturing process, a wheel spoke manufacturing process and a combined welding process.

[0036] The rim manufacturing process can be implemented with reference to the aforementioned first embodiment.

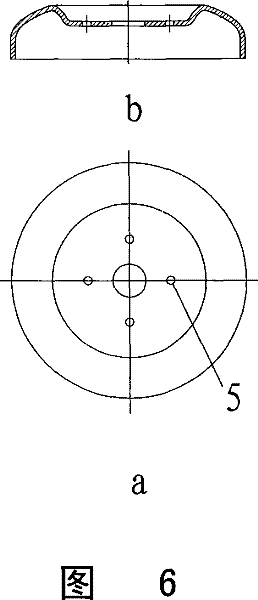

[0037] The spoke manufacturing process mainly includes a plate blanking step, a hot stretch forming step and a hot stamping step. The plate blanking step is shown in Figure 3. Heat the plate to 280°C-350°C, and then punch out the circular plate and the center hole on the plate. The thermal stretching step includes two thermal stretching steps in this embodiment, as shown in Figure 4 and Figure 5 respectively, of course, different thermal stretching steps can be selected for different spoke shapes, the thermal stretching step is, for example, in Heated stretching is carried out on a 200-ton double-action press, and the stretching temperature is between 280°C and 350°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com