Valve test device and method

A technology of a test device and a test method, applied in the field of adjustable valve test devices, can solve problems such as limitation of heating capacity, different working conditions, inability to continuously provide high-flow high-temperature test medium durability test, etc., and achieve the effect of improving test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

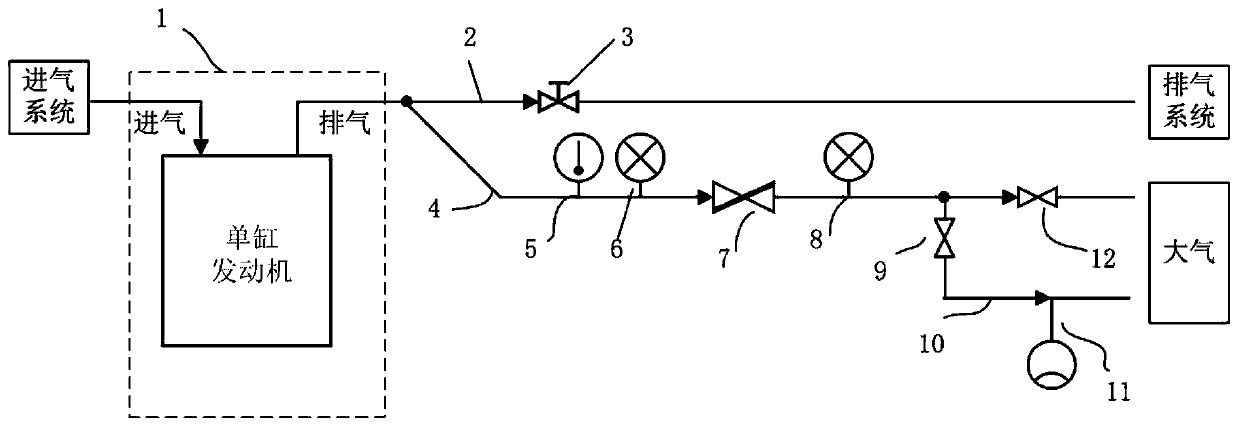

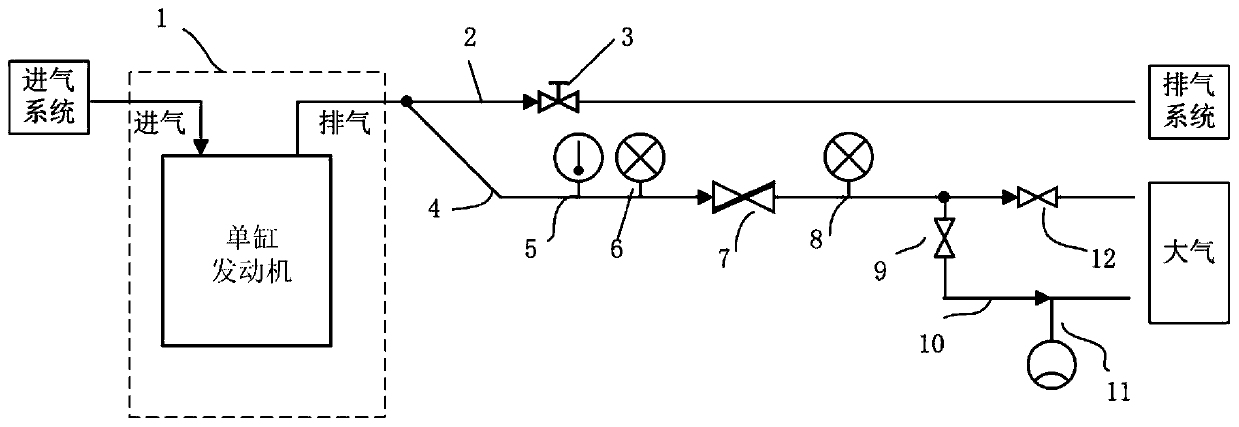

[0056] Open the switch valve 12 of the branch pipe, close the switch valve 9 of the lead pipe, start the single-cylinder engine 1, control the switch of the test valve 7 through the actuator of the test valve 7, and check the action and reliability of the test valve.

[0057] By adjusting the operation of the single-cylinder engine 1 and the opening of the valve 3, the temperature and pressure in front of the valve can be adjusted, and the operating conditions of the test valve can be changed:

[0058] If it is necessary to increase the working temperature, pressure and flow rate of the valve, the operating efficiency of the single-cylinder engine 1 can be increased. The greater the power of the single-cylinder engine, the more fuel it burns per unit time, and the greater the air volume required for fuel combustion. The single-cylinder engine Exhaust flow, temperature and pressure will also increase; if the operating temperature, pressure and flow of the valve need to be reduce...

Embodiment 2

[0062] Open the branch pipe switch valve 12, close the lead pipe switch valve 9, and open the test valve 7 to start the single-cylinder engine 1;

[0063] By adjusting the operating condition of the single-cylinder engine 1 and the opening of the regulating valve 3, the temperature and pressure in front of the valve can be adjusted, and the operating condition of the test valve can be changed. If the operating temperature, pressure and flow of the valve need to be increased, the operating condition of the single-cylinder engine 1 can be improved. , while appropriately reducing the opening of the regulating valve 3. If it is necessary to reduce the working temperature, pressure and flow of the valve, the operating condition of the single-cylinder engine 1 can be reduced, and the opening of the regulating valve 3 can be appropriately increased.

[0064] According to the difference between the measured values of the first pressure sensor 6 and the second pressure sensor 8, the ...

Embodiment 3

[0066] Close the test valve and the branch pipe switch valve 12, open the lead pipe switch valve 9, and start the single-cylinder engine 1;

[0067] By adjusting the operating conditions of the single-cylinder engine 1, the temperature and pressure before the valve can be changed. If the operating temperature, pressure and flow of the valve need to be increased, the operating conditions of the single-cylinder engine 1 can be improved, and the opening of the regulating valve 3 can be appropriately reduced. If it is necessary to reduce the working temperature, pressure and flow of the valve, the operating condition of the single-cylinder engine 1 can be reduced, and the opening of the regulating valve 3 can be appropriately increased;

[0068] Use the flow test device 11 to test the valve leakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com