A Mobile Supersonic Nozzle Continuous Measuring System

A supersonic nozzle and measurement system technology, applied in the direction of measuring devices, instruments, particle and sedimentation analysis, etc., can solve the problems of different pressure sensor models, inability to continuously measure nozzle pressure, poor consistency, etc., to overcome bad consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

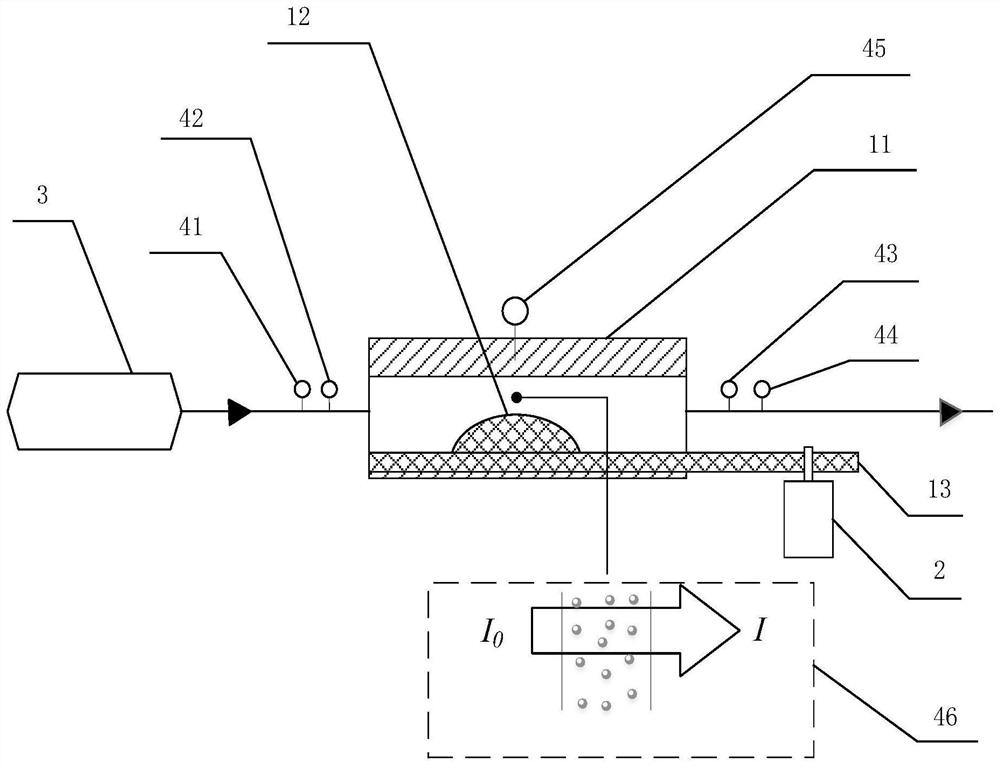

[0031] For the cross-sectional schematic diagram of the mobile supersonic nozzle experimental device, see figure 1 , including a mobile supersonic nozzle, a drive motor 2, an air source mechanism 3 and an experimental data measurement mechanism.

[0032] The mobile supersonic nozzle includes a nozzle base 11 , a rectangular nozzle 12 and a transmission rod 13 . The rectangular nozzle 12 is fixedly connected to the transmission rod 13, and the translational movement of the transmission rod 13 drives the rectangular nozzle 12 to perform a translational movement; The formed internal cavity constitutes the cross-sectional area of the mobile supersonic nozzle; due to the translation of the rectangular nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com