Method for quickly imaging absorption type defects of large-aperture reflecting film element

A thin-film element, absorbing technology, used in optical testing of flaws/defects, measuring devices, material analysis by optical means, etc., to achieve high-resolution and fast imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

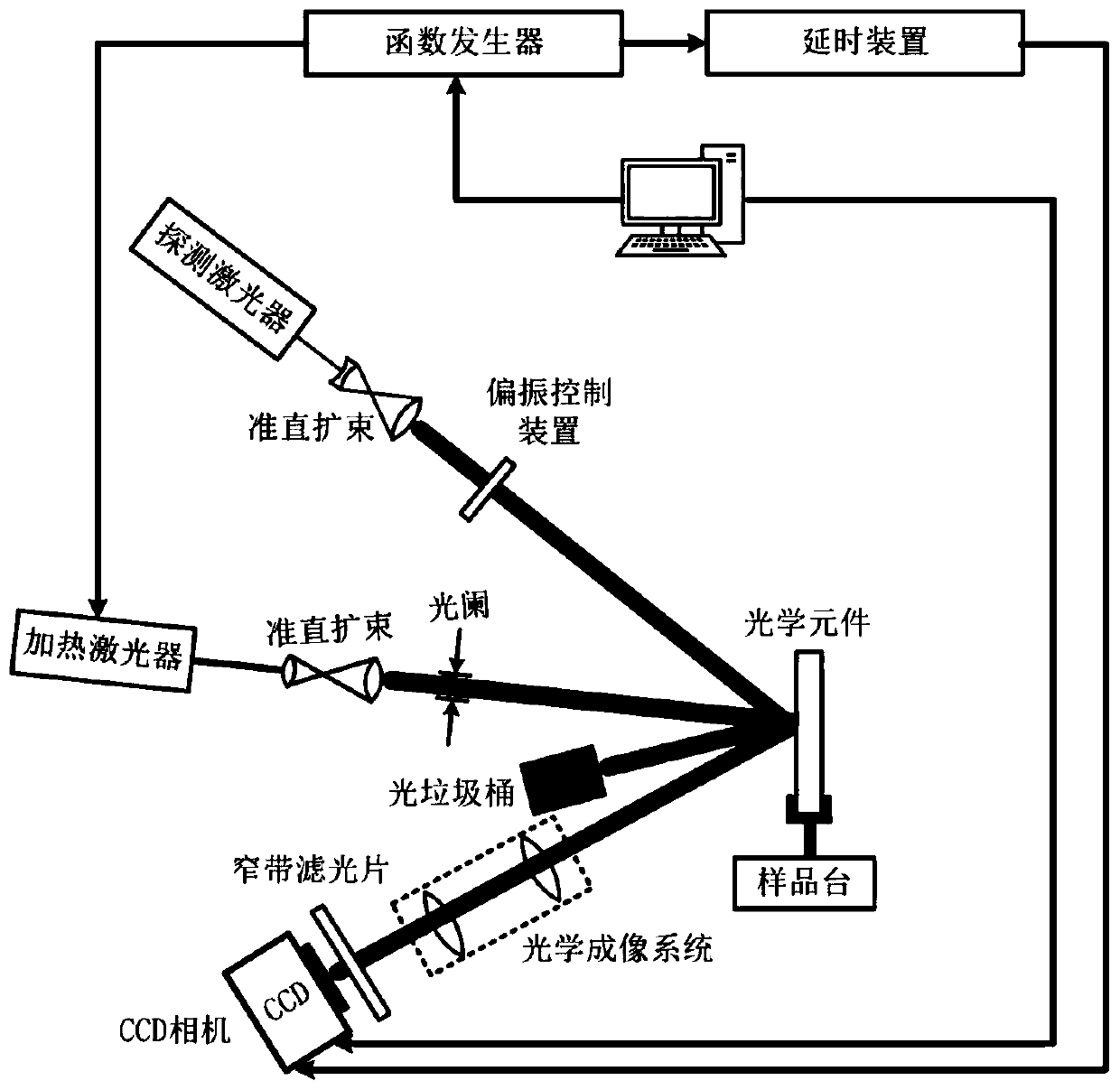

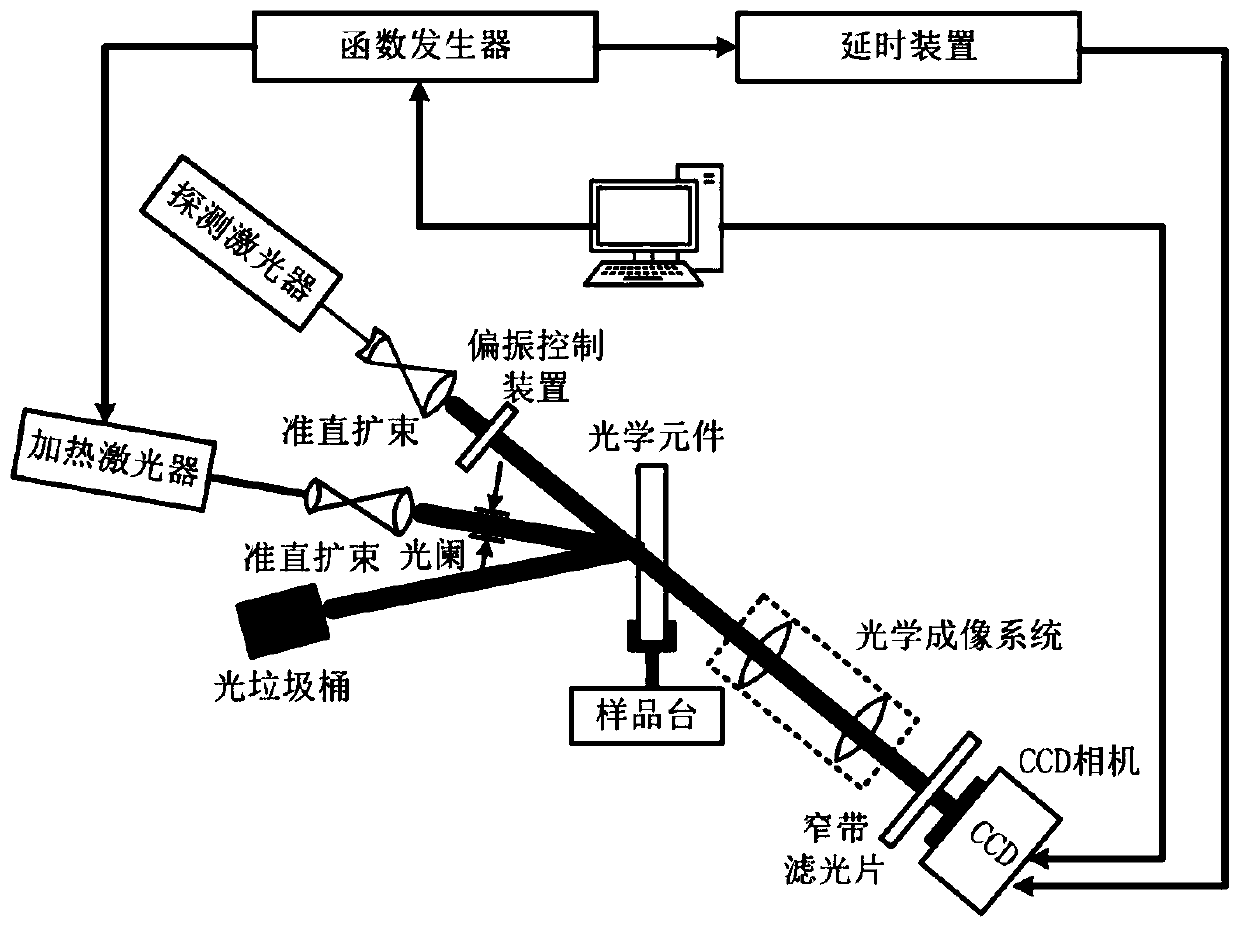

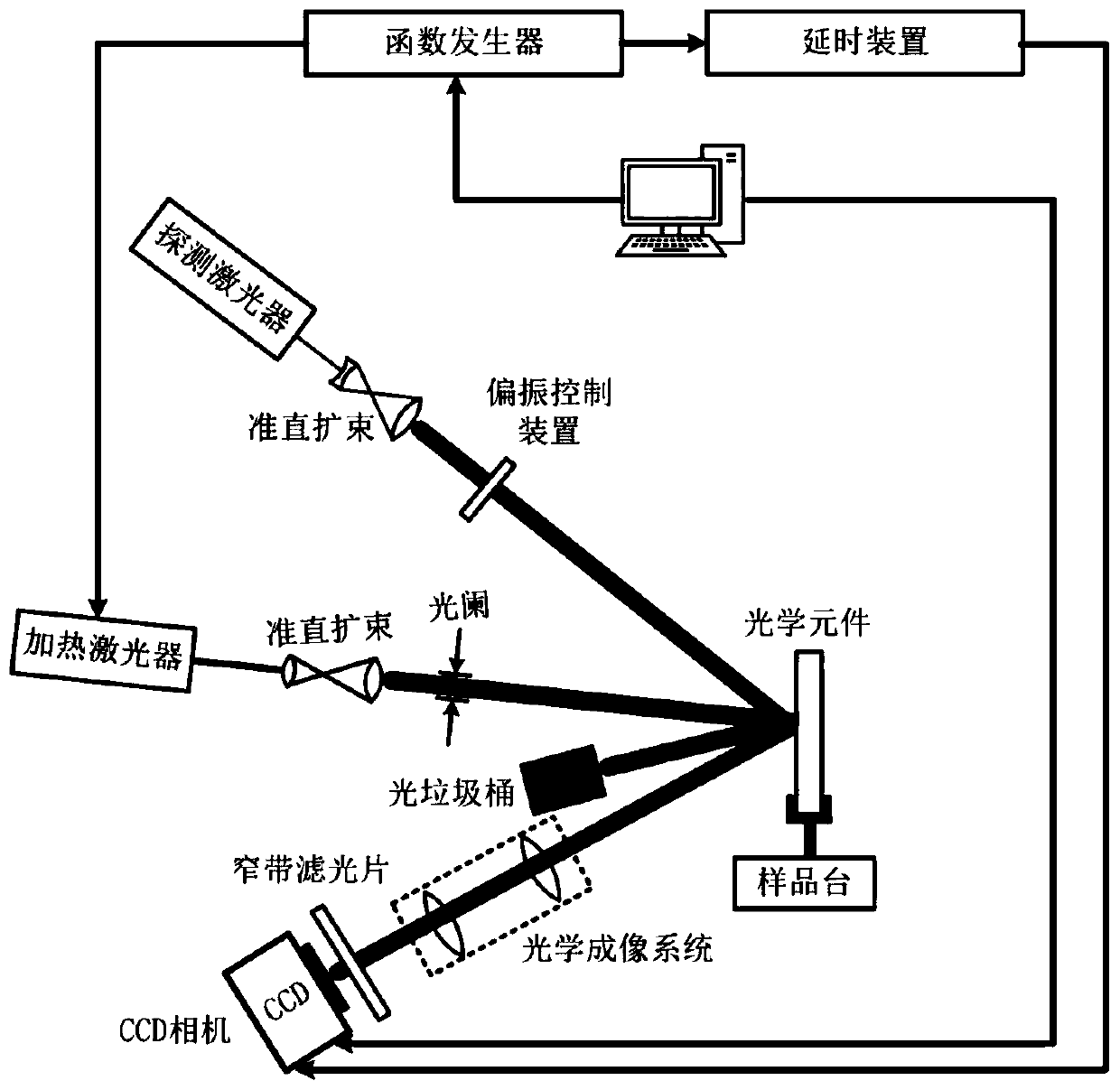

[0022] Combine below Figure 1-2 The invention specifically describes a rapid imaging method for the distribution of absorption-type defects in a large-diameter reflective film element proposed by the present invention. However, it should be understood that the drawings are only provided for a better understanding of the present invention, and should not be construed as limiting the present invention.

[0023] Such as figure 1 with 2 As shown, the measuring device that implements the method of the present invention can be a reflective measuring device or a transmissive measuring device, mainly composed of a high-power heating laser whose output can be modulated and its collimated beam expanding optical system, a low-power detection laser and its collimating expander Beam optical system, detection laser beam polarization control device, function generator, delay device, sample fixture and electronically controlled two-dimensional scanning translation stage, optical imaging device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com