Conductive material defect high-precision imaging detection method based on pulsed eddy current

A conductive material, pulsed eddy current technology, applied in the direction of material analysis, material analysis, material magnetic variables, etc. by electromagnetic means, can solve the problems of detection time influence, uncorrelated scanning speed and signal acquisition speed, low sensor accuracy, etc. Improved effectiveness and accuracy, rich data support, high defect scan detection resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

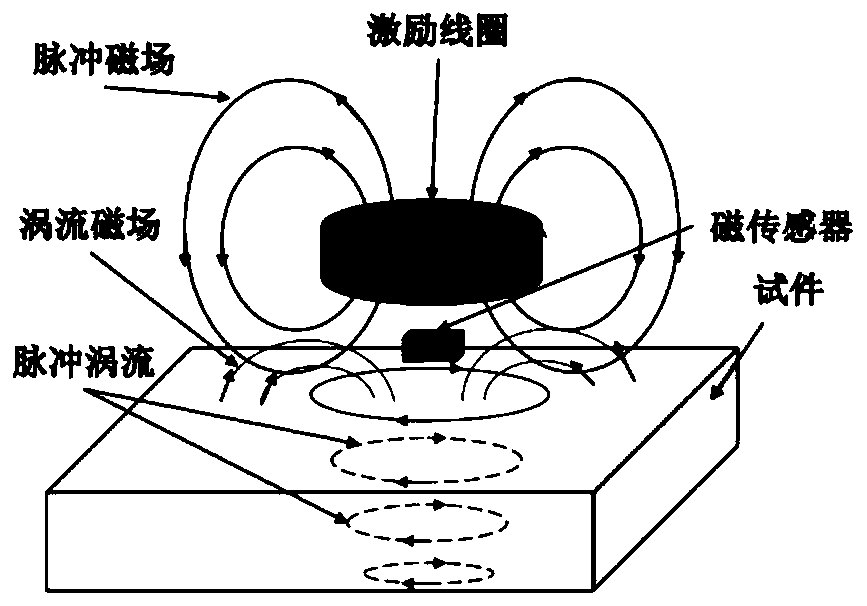

[0027] The invention provides a high-precision imaging detection method for conductive material defects based on pulsed eddy current. The principle of eddy current pulse nondestructive detection is as follows: figure 2 As shown, the pulsed magnetic field is induced by the excitation coil with pulsed voltage or current signal. When it is close to the surface of the conductor, the inside of the conductor forms a closed loop, and the electromagnetic induction effect occurs to generate a vortex-shaped induced current, that is, a pulsed eddy current. The eddy current will generate an eddy current magnetic field in space, and defects on the surface and inside of the conductor will affect the change of the eddy current magnetic field. Therefore, through the acquisition of the magnetic sensor, after signal processing and inversion, the surface and internal defects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com