Super-precise force clamp experimental method based on biofilm mechanical probe system

An experimental method, a biofilm technology, is applied in the field of quantitative detection of the dissociation rate of the interaction between biological macromolecules, which can solve the problems of poor accuracy of measurement results, wrong conclusions, inability to apply intermolecular interactions with slow dissociation rates, etc. problems, to achieve the effect of improving accuracy and extending the recording time limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with drawings and embodiments.

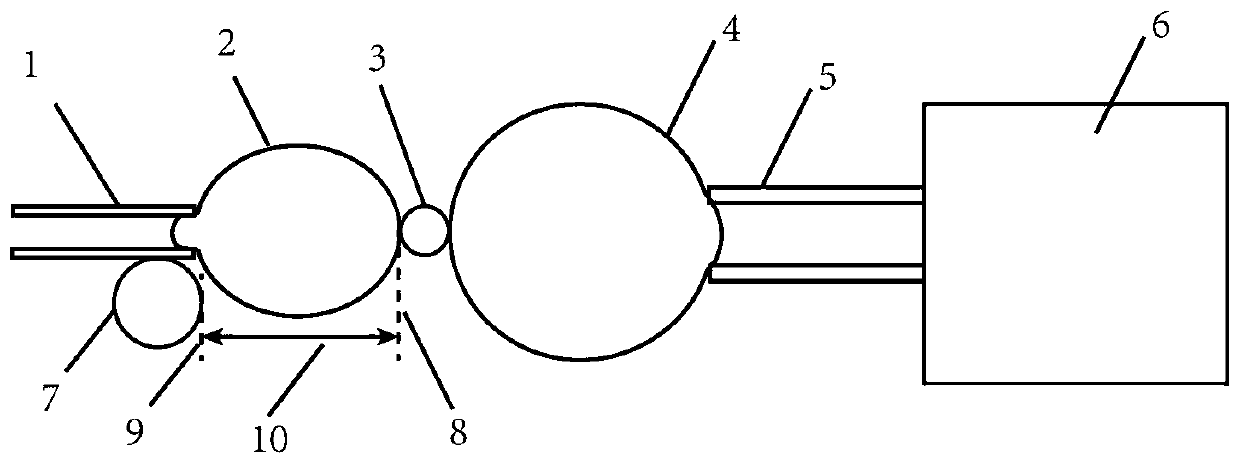

[0039] Such as figure 1As shown, the specific biofilm mechanics probe system includes a probe end and a target end, the probe end includes a first micropipette 1, red blood cells 2, probe beads 3 and reference beads 7, and the target end includes a cell / small The ball 4 and the second micropipette 5; the end of the first micropipette 1 draws red blood cells 2, the side of the end of the first micropipette 1 is stably connected with a reference ball 7 through the strong interaction between protein molecules, and the end of the second micropipette 5 Partially absorb the cells / ball 4, the cell / ball 4 expresses / coats a target protein molecule on the surface, if it is a cell 4, it expresses a target protein molecule, and if it is a small ball 4, the surface is coated with a target protein molecule; the probe The surface of the small ball 3 is coated with another target prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com