Internet of Things motor monitoring platform

A technology of motor monitoring and Internet of Things, which is applied in the direction of motor generator testing, measuring devices, instruments, etc., can solve problems such as the inability to know the operating status of motors, and achieve the effect of improving the quality of inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

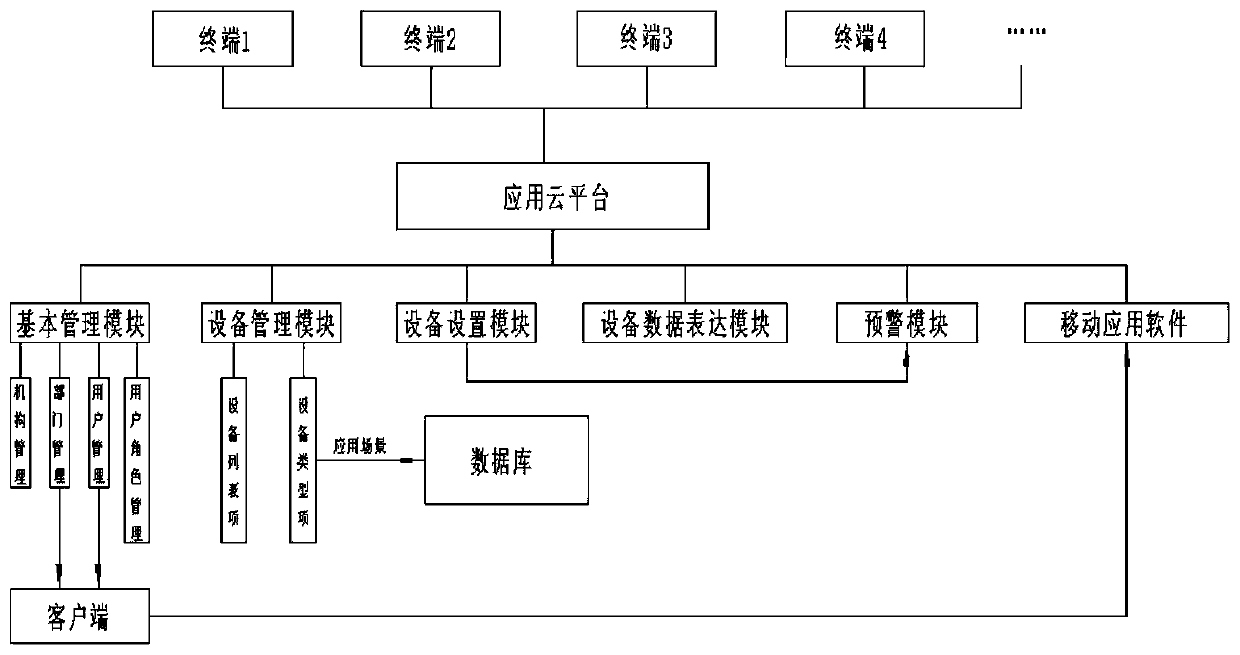

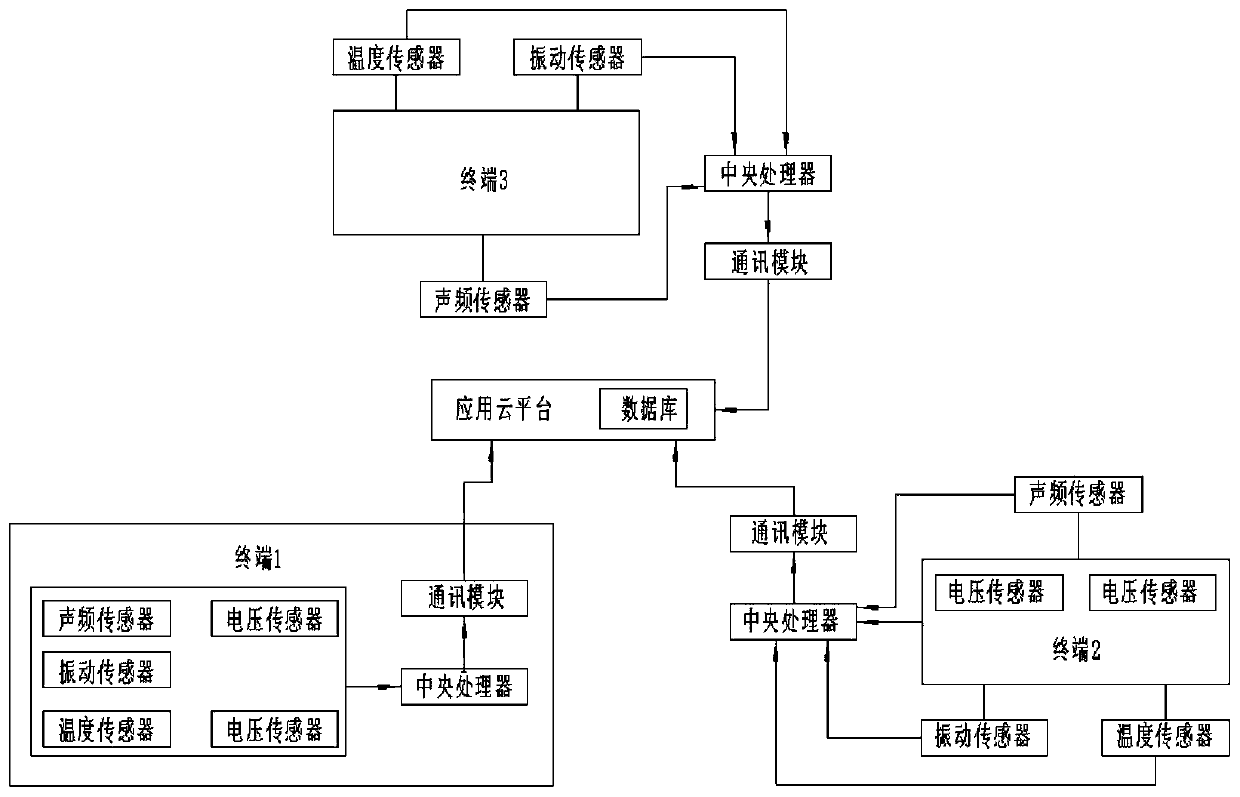

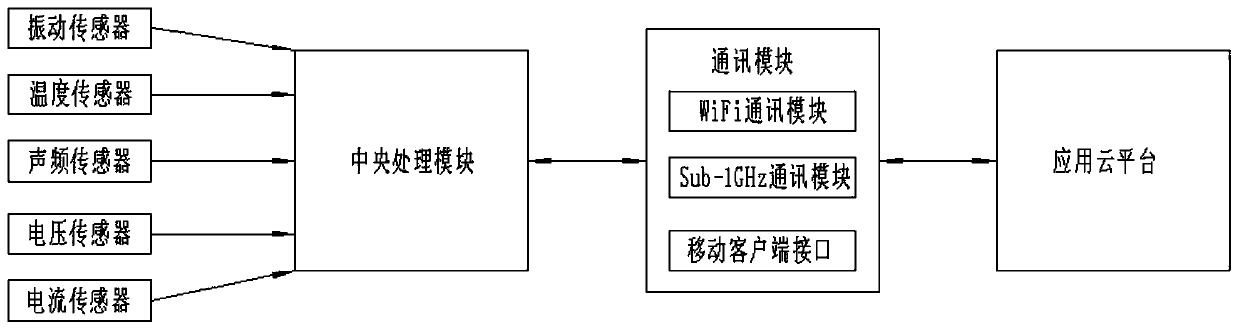

[0030] Embodiment 1: a kind of Internet of Things motor monitoring platform, including application cloud platform; as Figure 1-4 , installed on the front and rear ends of the bearing of the motor under test, audio frequency sensors, vibration sensors and temperature sensors; current sensors (3 phases) and voltage sensors (3 phases) installed in the distribution box of the motor under test; integrated audio frequency sensors, vibration The central processing unit and communication module for collecting information from sensors, temperature sensors, current sensors and voltage sensors; the collected information is encoded, and the collected audio frequency, vibration, temperature, voltage and current analog signal formats are converted into digital signals, Then transmit the digital signal to the communication module, the communication module transmits the digital signal to the application cloud platform, and the application cloud platform decodes the received digital signal. Th...

Embodiment 2

[0036] Embodiment 2: as figure 2 , the difference between this embodiment and Embodiment 1 is that the installation position of the information collection module is different, a motor monitoring platform for the Internet of Things, including an application cloud platform; an audio frequency sensor, a vibration sensor and a temperature sensor installed on the casing of the motor under test; Install the current sensor (3-phase) and the voltage sensor (3-phase) in the distribution box of the motor under test.

Embodiment 3

[0037] Embodiment 3: as figure 2 , this embodiment is built on the basis that embodiment 1 and embodiment 2 have constituted the database, and the difference is that the information collection module only has audio frequency sensors, vibration sensors and temperature sensors, and the audio frequency sensors, vibration sensors and temperature sensors are related to the central processing unit and the central processing unit. The communication module is integrated into a monitoring device. The monitoring device is placed on the surface of the motor to collect motor bearing information. The central processor encodes the monitoring information and sends the coded information to the application cloud platform through the communication module to compare and analyze the data of the motor bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com