A preparation method of a high -temperature flame retardant charging pile cable

A flame-retardant, charging pile technology, used in cable/conductor manufacturing, reducing the size of conductors/cables, insulating cables, etc., can solve the problems of easy accumulation in the human body, not meeting environmental protection requirements, etc. Strong stability and resistance to thermal decomposition, the effect of reducing temperature, improving mechanical strength and elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

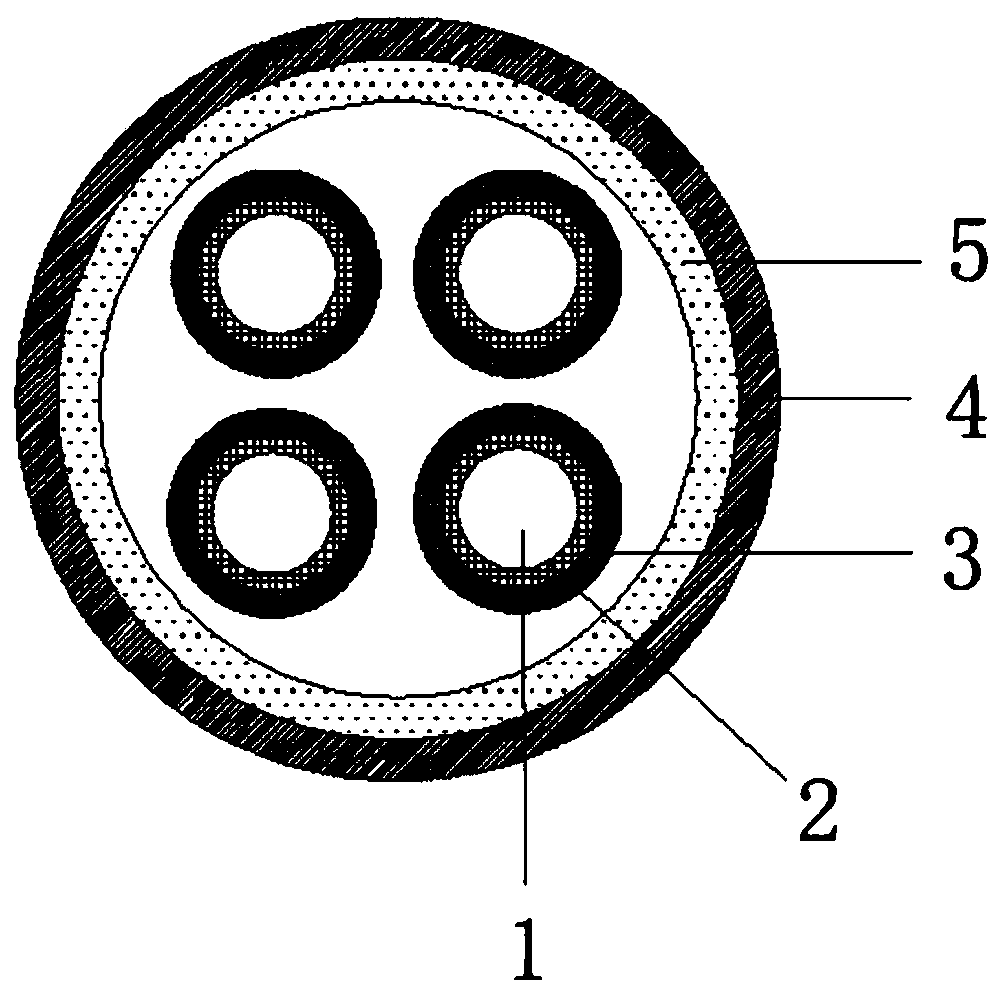

Image

Examples

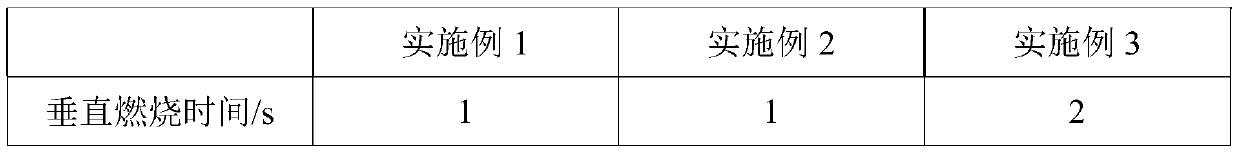

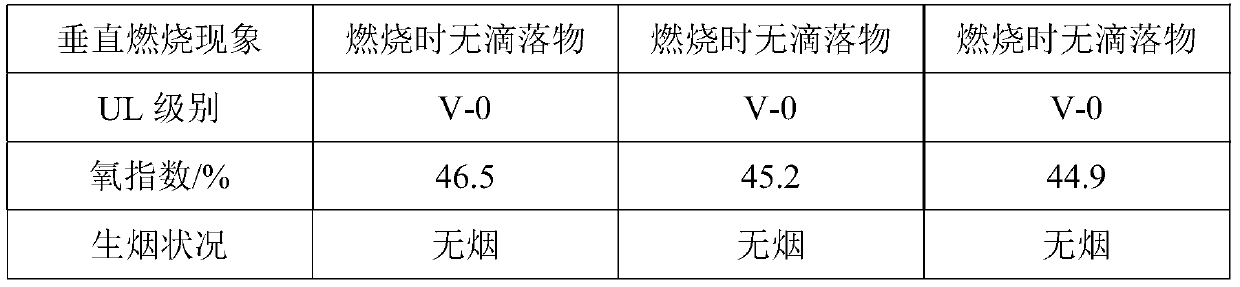

Embodiment 1

[0030] A preparation method of a high-temperature-resistant flame-retardant charging pile cable:

[0031] S1: Evenly apply a layer of wire drawing solution with a temperature of 50°C on the surface of the copper rod, and perform wire drawing on a wire drawing machine to obtain copper wire;

[0032] S2: Put the copper wire into the annealing furnace, raise the temperature to 560°C at a heating rate of 20°C / min, keep it warm for 2.5 hours, then lower the temperature to 410°C at a cooling rate of 10°C / min, hold it at a temperature of 1.5 hours, and cool naturally to At room temperature, twist a plurality of copper wires to obtain a copper wire;

[0033] S3: Weigh raw materials according to the following weight ratios:

[0034] 42 parts of silicone rubber, 18 parts of thermoplastic polyolefin elastomer, 16 parts of styrene block copolymer, 6 parts of melamine polyphosphate, 2 parts of modified zirconium phosphate, 21 parts of nano-organic montmorillonite, basic magnesium sulfate ...

Embodiment 2

[0043] A preparation method of a high-temperature-resistant flame-retardant charging pile cable:

[0044] S1: Evenly apply a layer of wire drawing solution with a temperature of 45°C on the surface of the copper rod, and perform wire drawing on a wire drawing machine to obtain copper wire;

[0045] S2: Put the copper wire into the annealing furnace, raise the temperature to 560°C at a heating rate of 25°C / min, keep it warm for 4 hours, then lower the temperature to 400°C at a cooling rate of 12°C / min, keep it warm for 1 hour, and cool down to room temperature naturally. Twisting multiple copper wires to obtain copper wires;

[0046] S3: Weigh raw materials according to the following weight ratios:

[0047] 50 parts of silicone rubber, 10 parts of thermoplastic polyolefin elastomer, 16 parts of styrene block copolymer, 3 parts of melamine polyphosphate, 4 parts of modified zirconium phosphate, 20 parts of nano-organic montmorillonite, basic magnesium sulfate whiskers 7 parts, 8...

Embodiment 3

[0056] A preparation method of a high-temperature-resistant flame-retardant charging pile cable:

[0057] S1: Evenly apply a layer of wire drawing solution with a temperature of 45°C on the surface of the copper rod, and perform wire drawing on a wire drawing machine to obtain copper wire;

[0058] S2: Put the copper wire into the annealing furnace, raise the temperature to 560-580°C at a heating rate of 20°C / min, keep it warm for 2 hours, then lower the temperature to 400°C at a cooling rate of 8°C / min, hold it for 1 hour, and cool naturally to At room temperature, twist a plurality of copper wires to obtain a copper wire;

[0059] S3: Weigh raw materials according to the following weight ratios:

[0060] 40 parts of silicone rubber, 10 parts of thermoplastic polyolefin elastomer, 15 parts of styrene block copolymer, 3 parts of melamine polyphosphate, 2 parts of modified zirconium phosphate, 20 parts of nano-organic montmorillonite, basic magnesium sulfate whiskers 5 parts,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com