Liquid cooling assisted phase-change material heat exchange battery thermal management system

A battery thermal management and phase change material technology, applied in the field of battery thermal management systems, can solve the problems of limited heat transfer area, reduce battery temperature, increase cost and environmental pollution, achieve good heat storage effect and reduce additional power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in further detail below in conjunction with accompanying drawing:

[0039] For the battery thermal management module, there are two different preferred solutions:

[0040] Preferred option one:

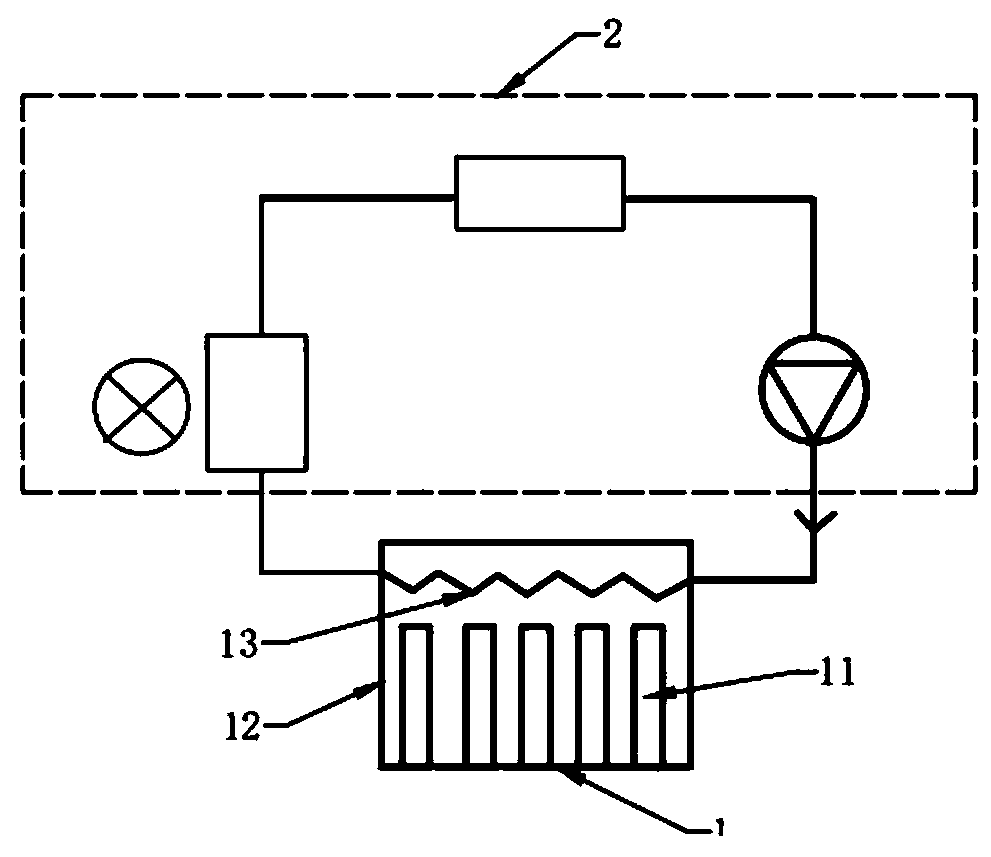

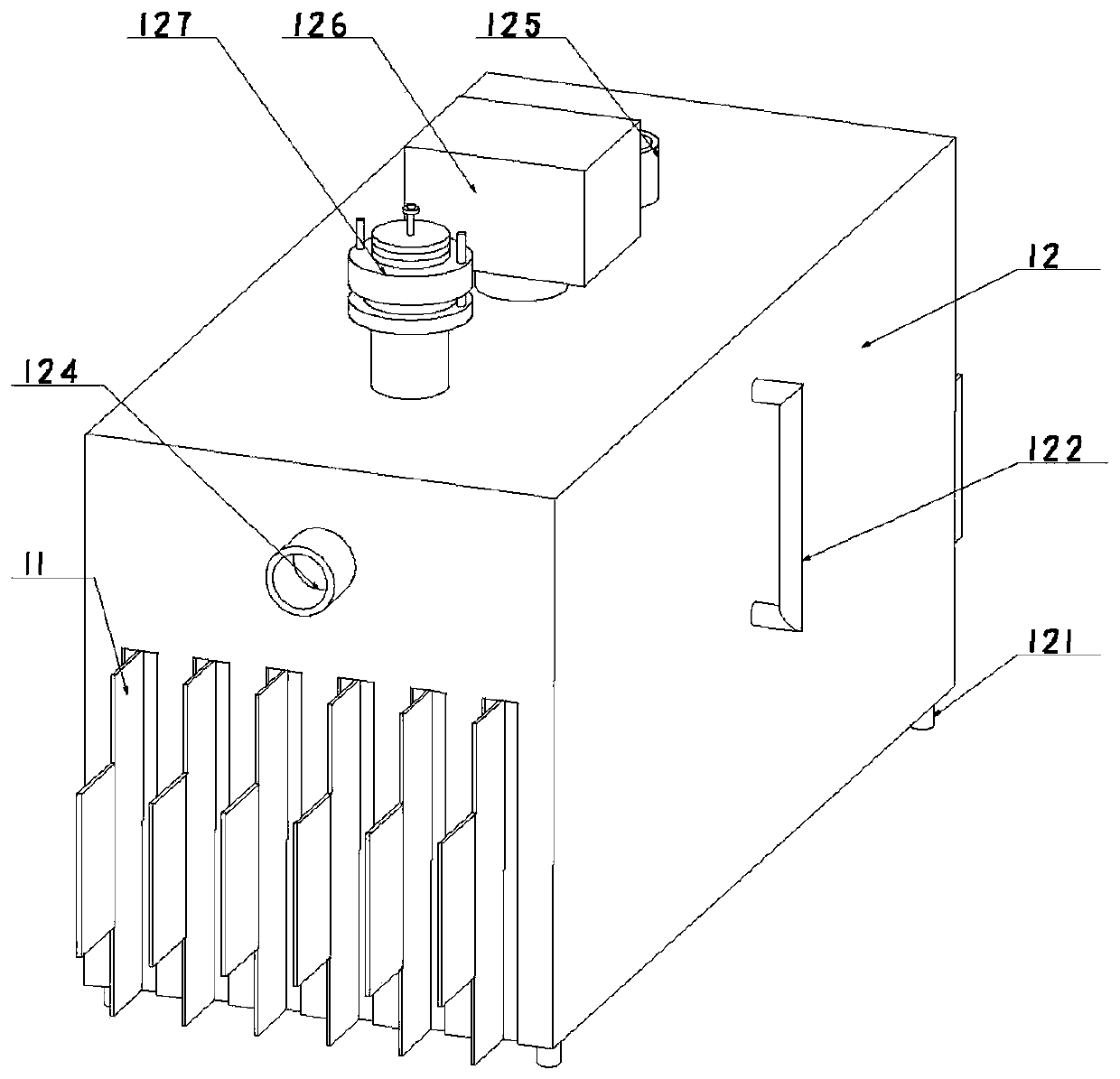

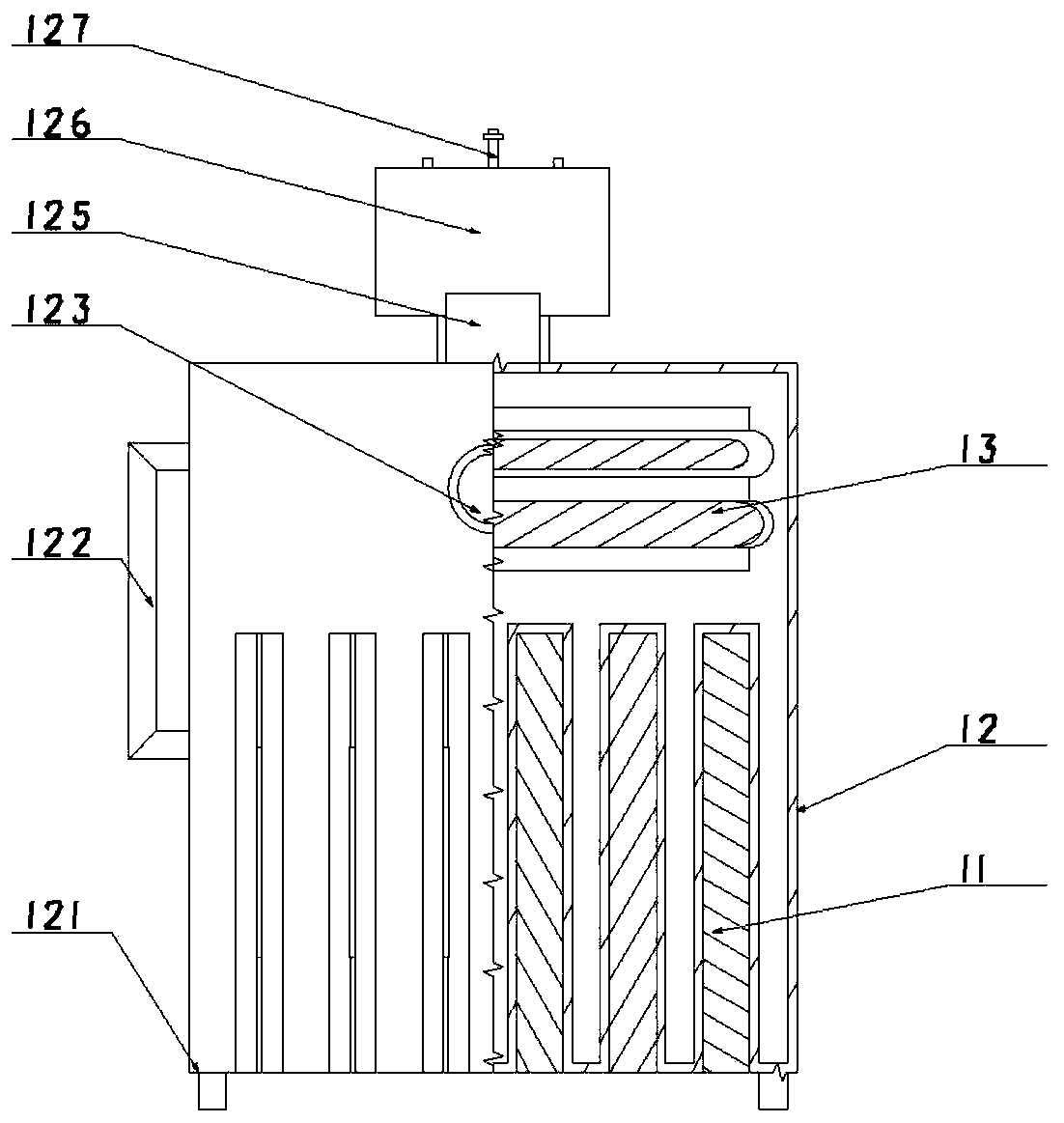

[0041] Such as figure 1 and figure 2 As shown, a battery thermal management system with liquid-cooled auxiliary phase change material heat exchange includes a liquid-cooled auxiliary system 2 and a battery thermal management module 1, and the liquid-cooled auxiliary system 2 passes through a liquid-cooled heat exchanger 13 and a battery thermal management system. The modules 1 are connected; the battery thermal management module 1 is composed of a module casing 12, a battery module 11 and a liquid-cooled heat exchanger 13. The module casing 12 is a sealed vacuum container formed by a forming process, and its interior is filled with phase variable material, and the battery module is embedded in the groove at the lower part; the battery modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com