Anti-reflection system and method for fiber laser

A fiber laser and anti-reflection technology, applied in the field of anti-reflection systems, can solve the problems of difficulty in controlling the reflection direction and intensity of reflected light from the workpiece, unstable laser output spectrum, and output power jitter, etc., to improve the optical transmission efficiency. , the structure is simple, the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

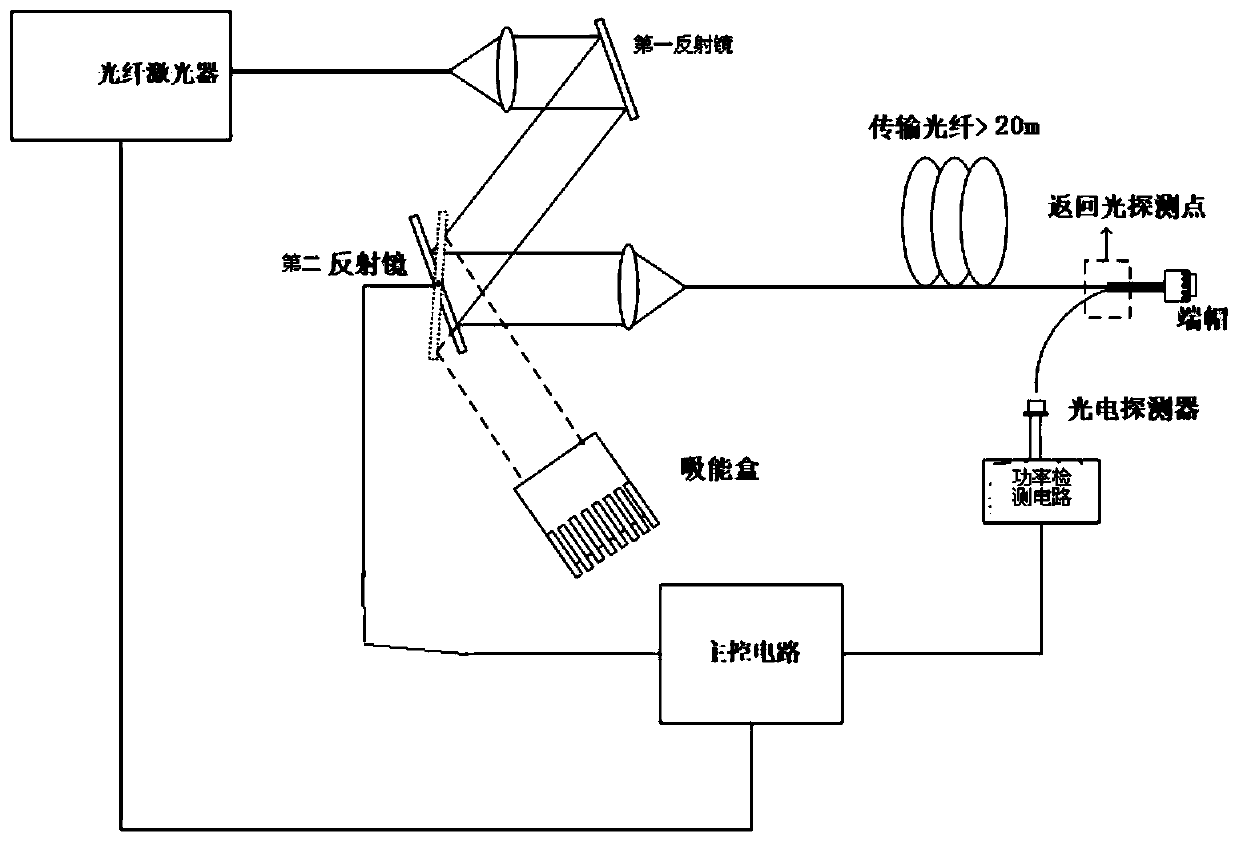

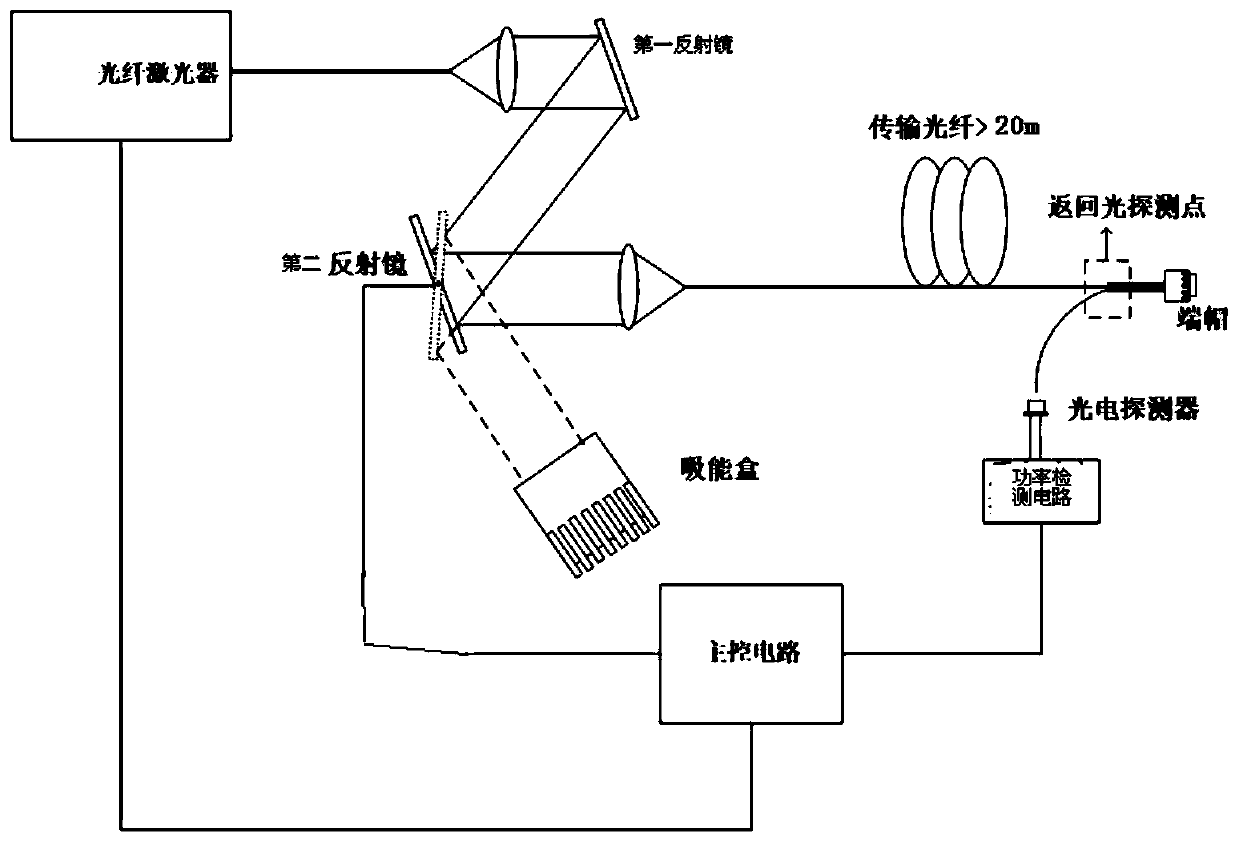

[0032] Such as figure 1 and figure 2 As shown, an anti-reflection system for a fiber laser, the anti-reflection system includes a first reflector, a second reflector, a first collimator, a second collimator, an energy-absorbing box, a transmission fiber, and an end cap , photodetector and main control circuit;

[0033] The second mirror is an adjustable mirror, and the adjustable reflection angle is 0-10°;

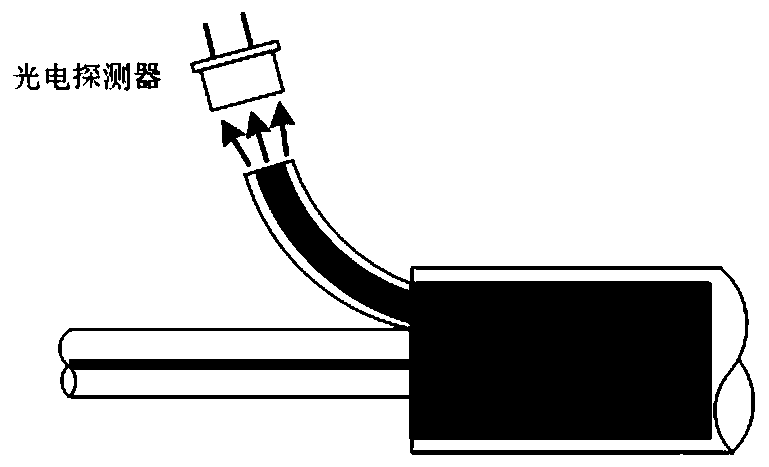

[0034] The end cap is welded to one end of the transmission fiber, the connection point between the end cap and the transmission fiber is the return light detection point, and the other end of the transmission fiber is fixedly connected to the second collimator;

[0035] When the workpiece to be processed is processed, the laser light emitted by the fiber laser passes through the first collimator, the first reflector, the second reflector, and the second collimator in sequence, and then is transmitted to the end cap through the transmission fiber, and then transmitted t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com