Exchangeable wearing part for an arc welding torch, holder for an exchangeable wearing part, and an arc welding torch having such a corresponding wearing part and holder

A technology of arc welding torch and support system, applied to replaceable wear parts for arc welding torches, support for replaceable wear parts, which can solve the problems of unfavorable heat transfer, high current transmission resistance, poor quality of welding connections, etc. , to achieve reliable current transmission and heat transfer, high process security, and favorable wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

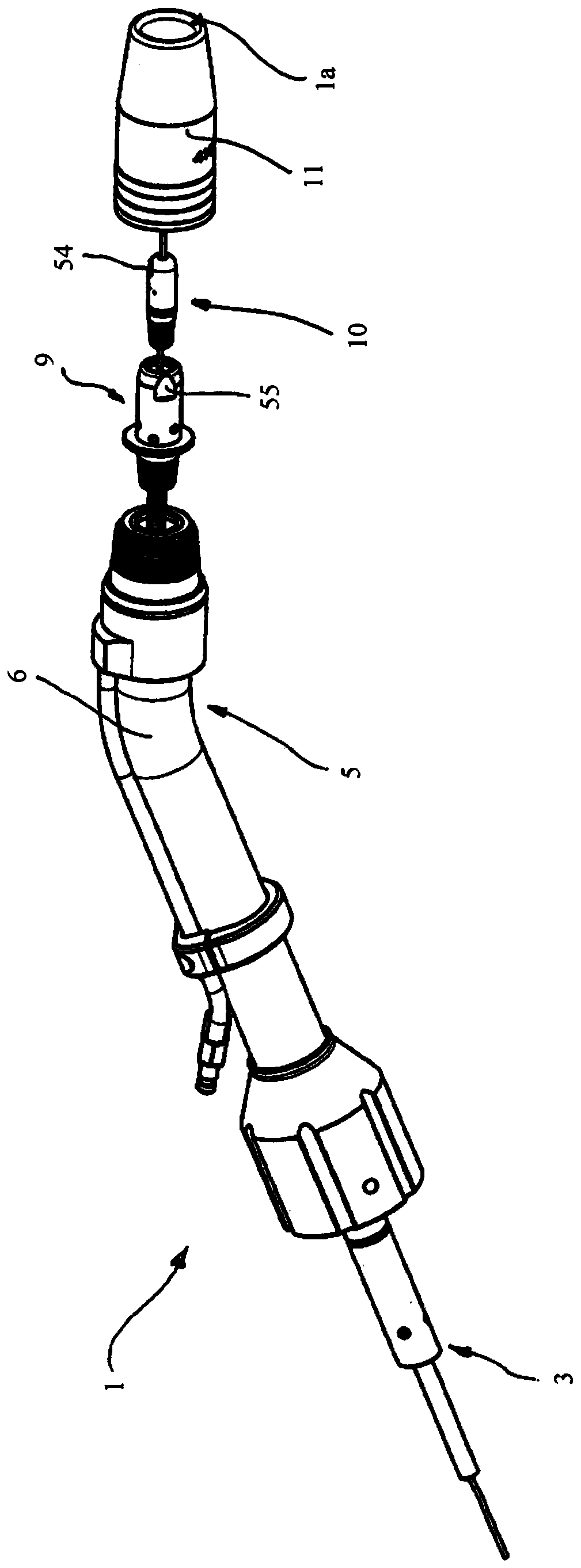

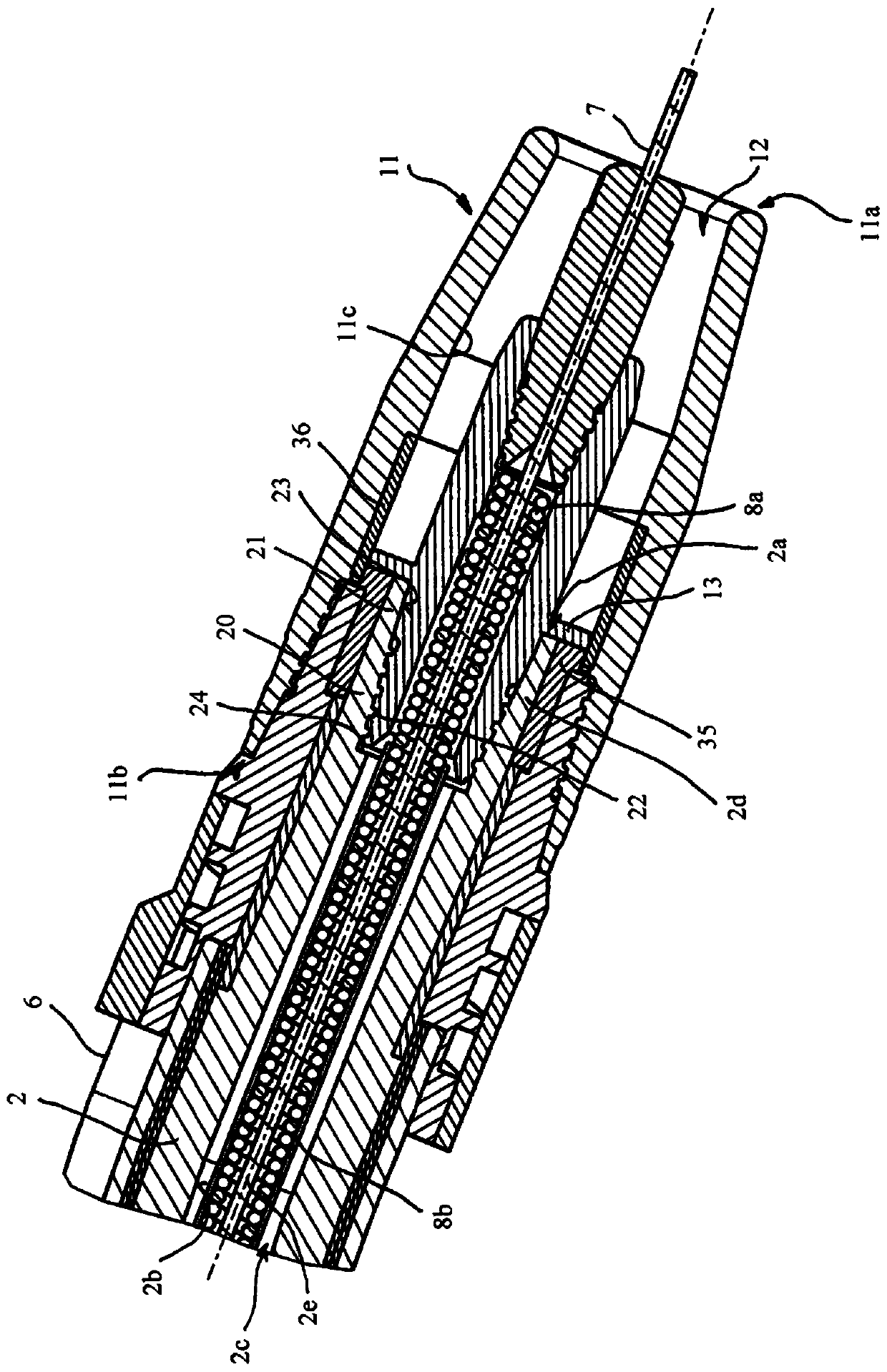

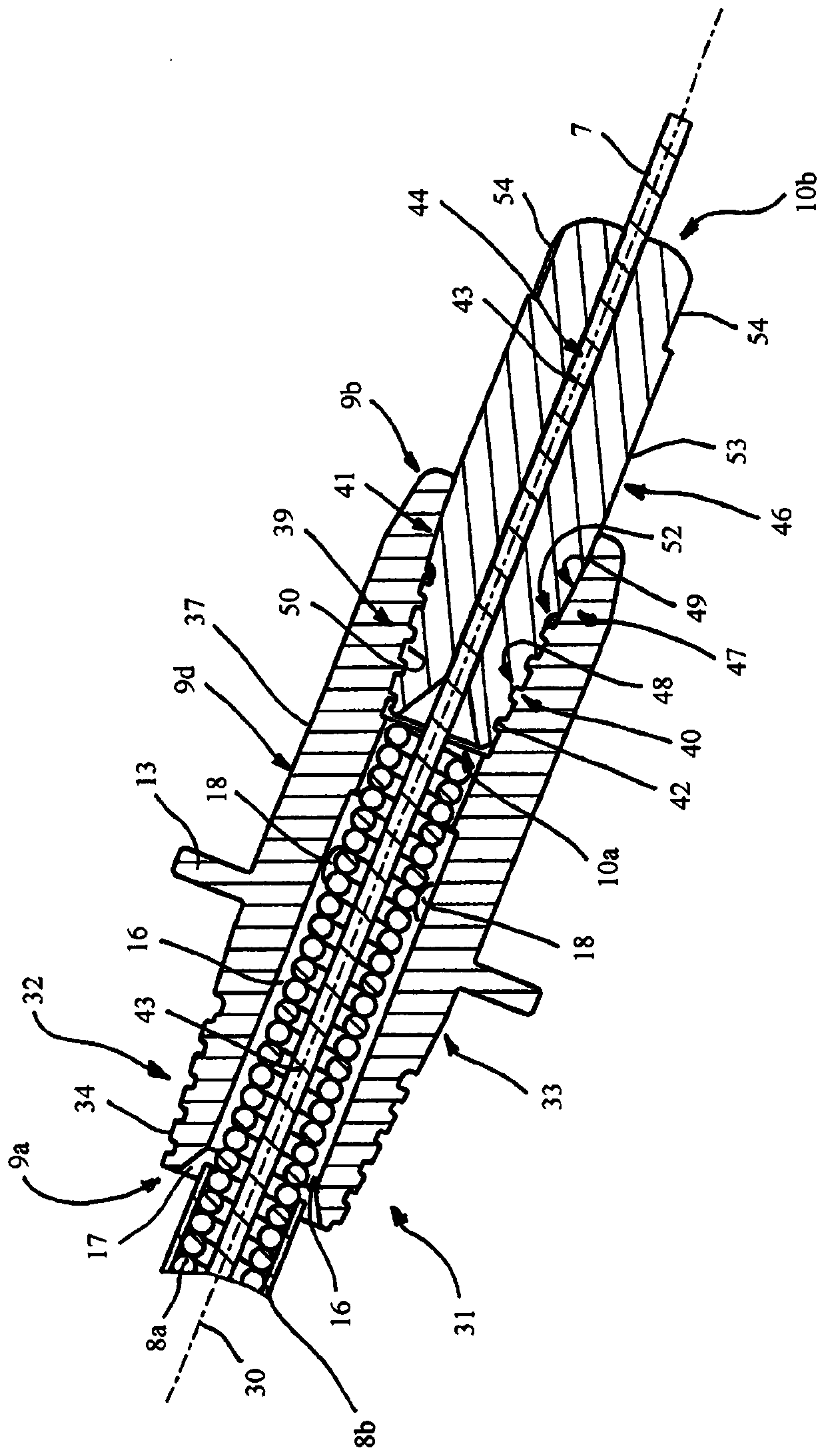

[0033] figure 1 A preferred embodiment of the arc welding torch 1 of the present invention is shown. The arc welding torch 1 is suitable for use in an automatic welding machine, such as a welding robot. In this case, the arc welding torch 1 is arranged on an end effector, not shown in detail, which is movable in different spatial directions, preferably in all spatial directions, along any desired feed path. This allows the end effector to move along with the arc torch on its feed path, and the arc torch can create a weld on the workpiece. In this case, the arc welding torch can preferably be constructed in principle in the same way as the arc welding torch disclosed in WO 2005 / 049259 A1, wherein in figure 1 There is a difference in the end zone of the arc welding torch in , which will be explained below. A non-essential but particularly preferred embodiment of the arc welding torch, in which the arc welding torch has an outer stator part and The rotor member is on the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com