Production method of instant fruits

A production method and fruit technology, which are applied to the preservation of fruits and vegetables, the protection of fruits/vegetables with a protective layer, and the preservation of fruits/vegetables by freezing/refrigeration, etc. Retention rate, fermentation-promoting effect, permeation-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

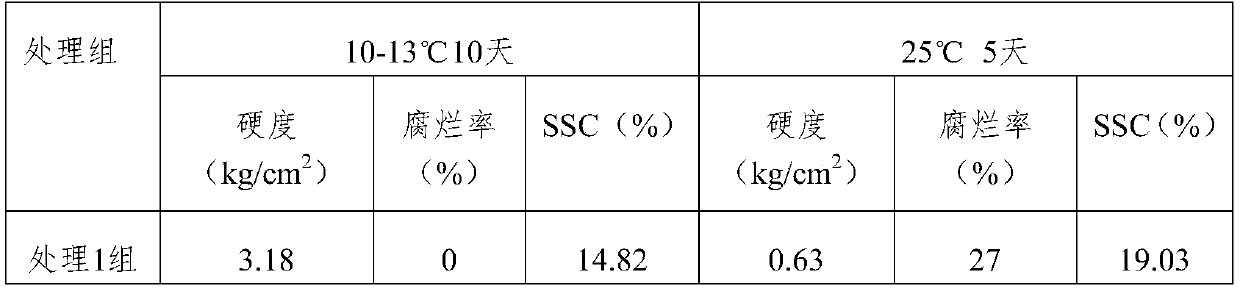

Embodiment 1

[0037] Embodiment 1 A kind of production method of instant kiwi fruit

[0038] Including the following steps:

[0039] 1) Picking, picking "Guichang" kiwifruit with an SSC of 6.5-7.5%;

[0040] 2) Sorting, picking out other fruits;

[0041]3) Ultrasonic-assisted chilling injury: Spray loquat / rose compound emulsion with a mass fraction of 0.07% into the chilling environment with an ultrasonic humidifier during the chilling injury process at -2.5°C, and use ultrasonic waves with a frequency of 40 kHz to treat the chilling injury during the cooling injury treatment process. The fruit is processed for 5 minutes; the initial frequency of the ultrasonic humidifier is 25kHz, and the terminal frequency is 120kHz. Its work is to work at the initial frequency for 10s, then increase to the terminal frequency within 30s, and then continue to work at the terminal frequency; The processing time is 5 minutes after the product temperature reaches -2.5°C;

[0042] 4) Return to temperature: ...

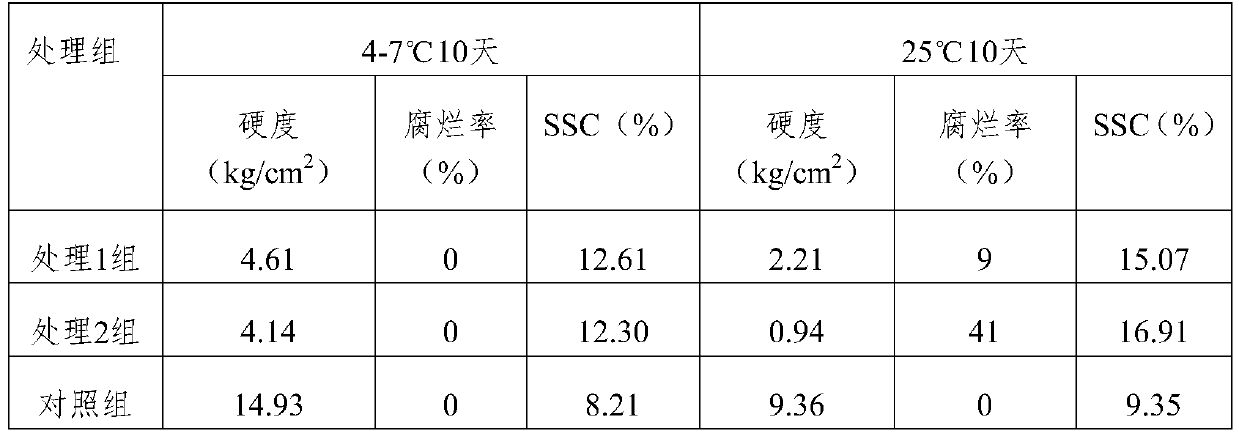

Embodiment 2

[0056] Embodiment 2 A kind of production method of instant apple

[0057] Including the following steps:

[0058] 1) Picking; Picking SSC in 11-13% "Gala" apples, the hardness is 5.7-7.0kg / cm 2 ;

[0059] 2) Sorting, picking out other fruits;

[0060] 3) Ultrasonic assisted chilling injury: Spray 0.1% loquat / rose compound emulsion into the chilling environment with an ultrasonic humidifier during the chilling injury process at -2°C, and use ultrasonic waves with a frequency of 43 kHz to treat the chilling injury Fruits are processed; the initial frequency of the ultrasonic humidifier is 30kHz, and the terminal frequency is 120kHz. Its work is to work at the initial frequency for 20s, then increase to the terminal frequency within 35s, and then continue to work at the terminal frequency; The time is to keep the temperature for 5 minutes after the product temperature reaches -2°C;

[0061] 4) Return to temperature: heat up to 25°C at a rate of 0.5°C / min;

[0062] 5) Ultraso...

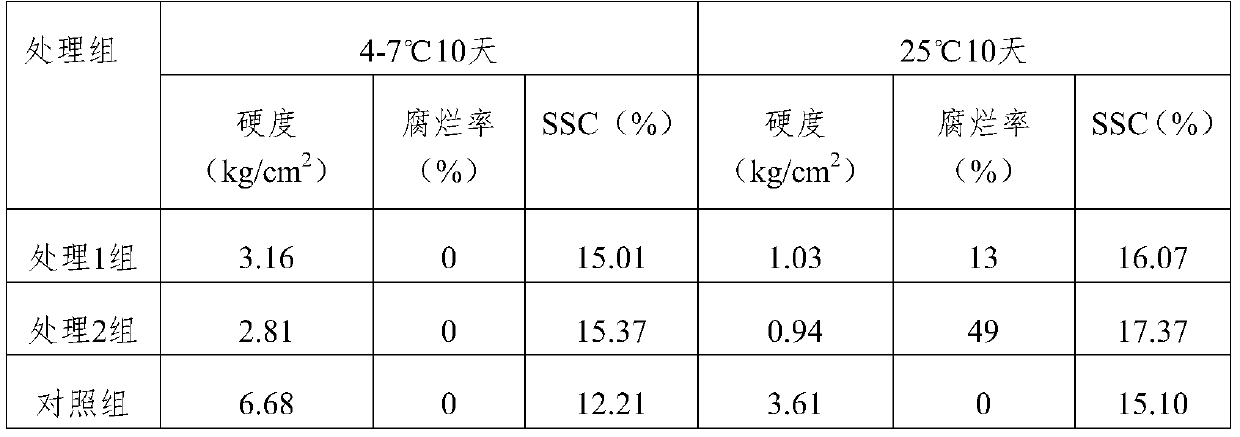

Embodiment 3

[0076] Embodiment 3 A kind of production method of instant banana

[0077] Including the following steps:

[0078] 1) Picking; Picking SSC in 1.0-2.0% green fruit banana apple, the hardness is 6.5-8.5kg / cm 2 ;

[0079] 2) Sorting, picking out other fruits;

[0080]3) Ultrasonic-assisted chilling injury: Spray 0.1% loquat / rose compound emulsion into the chilling environment with an ultrasonic humidifier during the chilling injury process at 8°C, and use ultrasonic waves with a frequency of 43 kHz to treat the fruit during the chilling injury treatment process. process; the initial frequency of the ultrasonic humidifier is 30kHz, and the terminal frequency is 130kHz, and its work is to work at the initial frequency for 20s, then increase to the terminal frequency within 35s, and then continue to work at the terminal frequency; The time is to keep warm for 5 minutes after the product temperature reaches 8°C;

[0081] 4) Return to temperature: heat up to 15°C at a rate of 0.3°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com