Imidazole ionic liquid functionalized zinc porphyrin and application thereof

An imidazole ionic liquid, functionalized technology, applied in the field of chemistry, can solve the problems of harsh reaction conditions, addition of solvents, low reactivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

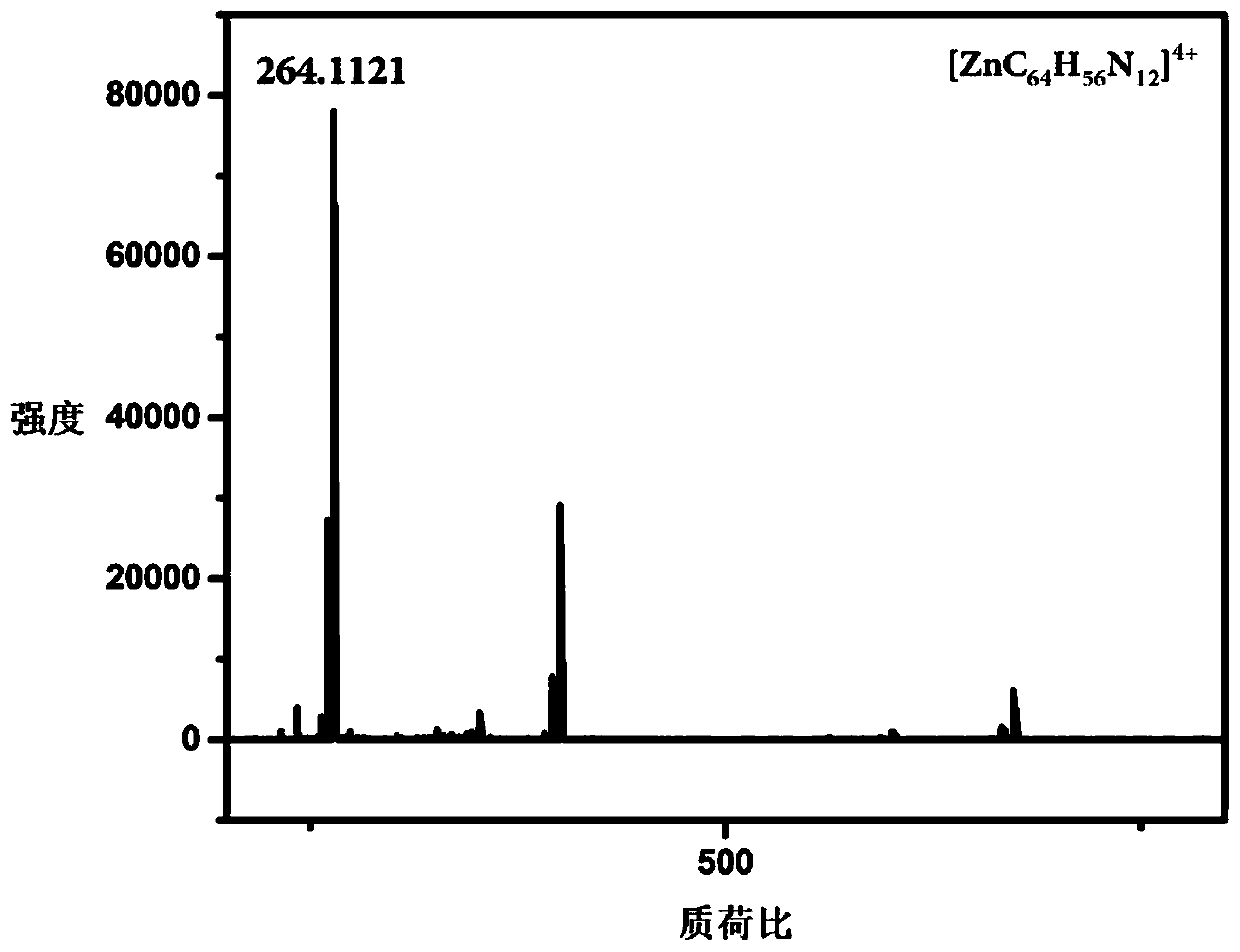

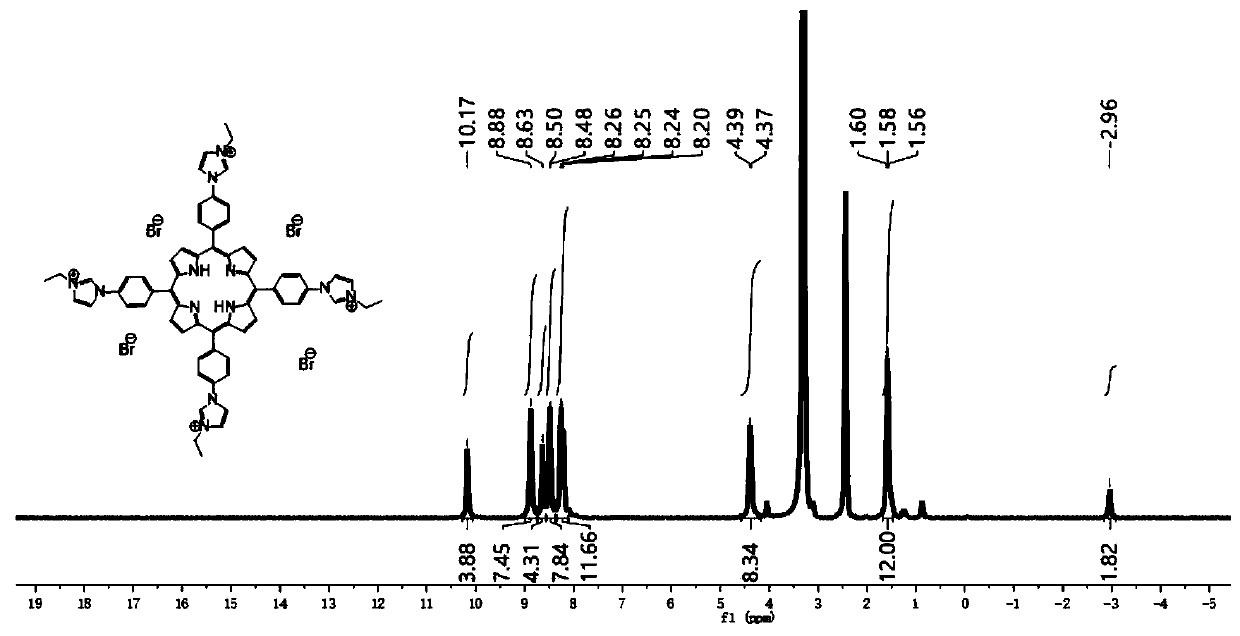

[0033] 1. Synthesis of zinc porphyrin functionalized with imidazolium ionic liquid

[0034] Its molecular structure of the imidazolium ionic liquid functionalized zinc porphyrin provided by the invention is as follows:

[0035]

[0036] The ZnPp-4EtIm + Br - The synthesis of is divided into two steps:

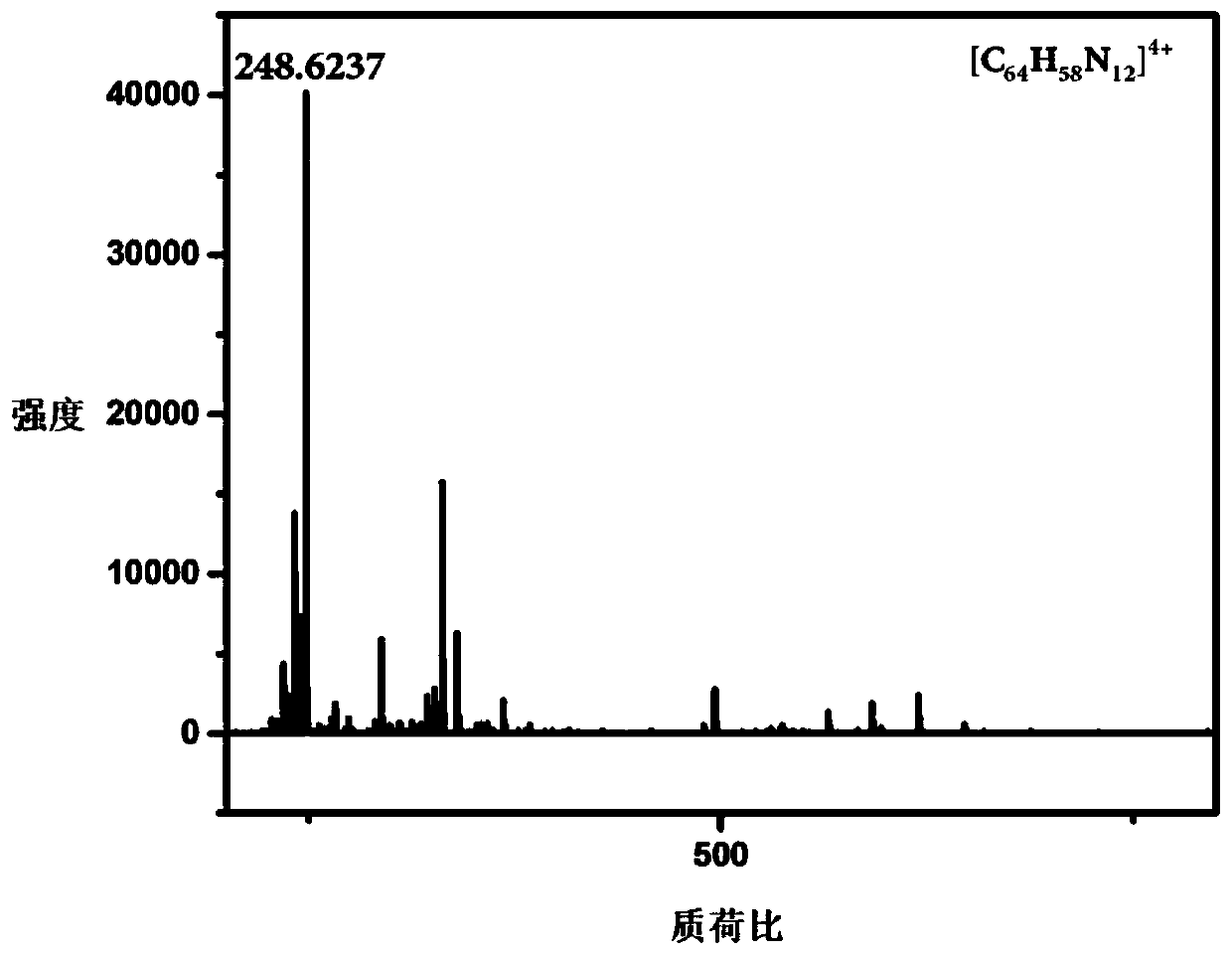

[0037] 1. Synthesis of H 2 Pp-4EtIm + Br -

[0038] In a 250mL three-necked flask, 100mL DMF (solvent) was added, then 0.44g5,10,15,20-tetrakis(4-imidazolyl)phenylporphyrin and 6.0g ethyl p-toluenesulfonate were dissolved in DMF, and then Heat to 100°C and reflux for 72 hours. After the reaction, DMF is distilled off under reduced pressure. After cooling to room temperature, 40 mL of water is added, and then washed with chloroform for several times until the lower chloroform layer has no color. Remove the chloroform layer and ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com