A high-performance catalyst for carbon dioxide resource utilization and its preparation method

A carbon dioxide, resource-recycling technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low efficiency of heterogeneous catalysts and high preparation costs, The effects of simple preparation method, low preparation cost and easy-to-obtain raw materials are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing a high-performance catalyst for carbon dioxide resource utilization includes the following steps:

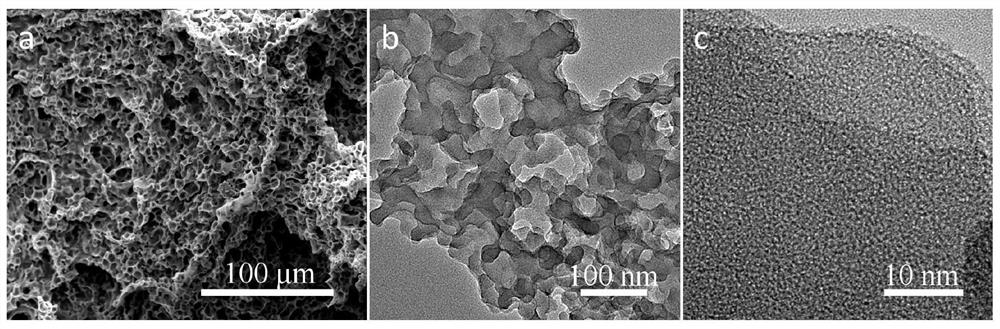

[0022] According to the mass ratio of 1:0.43:4.1:11.6, the melamine, paraformaldehyde and F127 emulsion stabilizer is dissolved in dimethyl sulfoxide (DMSO), and then Isopar is added dropwise TM M, DMSO and Isopar TM The volume ratio of M is 1:3.3, stirred to form a high internal phase emulsion, heated to 170°C, reacted for 72 hours, washed with acetone, tetrahydrofuran, dichloroethane and water, and filtered to obtain a solid. The solid was soaked in 0.1mol / L zinc chloride aqueous solution for 24 hours, filter, and dry the solid to obtain a high-performance catalyst for carbon dioxide resource utilization, see figure 1 .

[0023] As can be seen from the figure, the figure a shows that there are a large number of macroporous structures in the structure, and the figure b shows that there are mesoporous channels in the pore walls at the same time. The ...

Embodiment 2

[0031] The preparation method of a high-performance catalyst for carbon dioxide resource utilization includes the following steps:

[0032] According to the mass ratio of 1:1.6:4.5:13, the melamine, paraformaldehyde and F127 emulsion stabilizer is dissolved in dimethyl sulfoxide (DMSO), and then Isopar is added dropwise TM M, DMSO and Isopar TM The volume ratio of M is 1:5, stir to form a high internal phase emulsion, heat to 170°C, react for 72 hours, wash with acetone, tetrahydrofuran, dichloroethane and water in turn, filter to obtain a solid, soak the solid in 0.1mol / L zinc chloride aqueous solution for 18 hours, filter and dry the solid to obtain a high-performance catalyst for carbon dioxide recycling.

[0033] The conversion rate of propylene carbonate was 68.1%, and the TOF was 13451.

Embodiment 3

[0035] The preparation method of a high-performance catalyst for carbon dioxide resource utilization includes the following steps:

[0036] According to the mass ratio of 1:0.4:1.5:5, the melamine, paraformaldehyde and F127 emulsion stabilizer is dissolved in dimethyl sulfoxide (DMSO), and then Isopar is added dropwise TM M, DMSO and Isopar TM The volume ratio of M is 1:3, stir to form a high internal phase emulsion, heat to 170°C, react for 72 hours, wash with acetone, tetrahydrofuran, dichloroethane and water in turn, filter to obtain a solid, soak the solid in 0.1mol / L zinc chloride aqueous solution for 24 hours, filter and dry the solid to obtain a high-performance catalyst for carbon dioxide recycling.

[0037] It was measured that the conversion rate of propylene carbonate was 67.2%, and the TOF was 13642.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com