Method for co-catalyzing ring-opening polymerization of carbon dioxide and alkylene oxide by organic base and hemicellulose

A technology of co-catalyzing carbon dioxide and hemicellulose, applied in the direction of organic chemistry, etc., can solve the problem of immature use methods, and achieve the effect of easy disposal and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of the blend: Add 0.075g of hemicellulose, 2mL of dichloromethane, 5mL of propylene oxide, and organic base 1,8-diazabicycloundecone into a 25mL polytetrafluoroethylene substrate Carb-7-ene (DBU) 0.368mL (DBU:hemicellulose=5:1(w:w)), stir well.

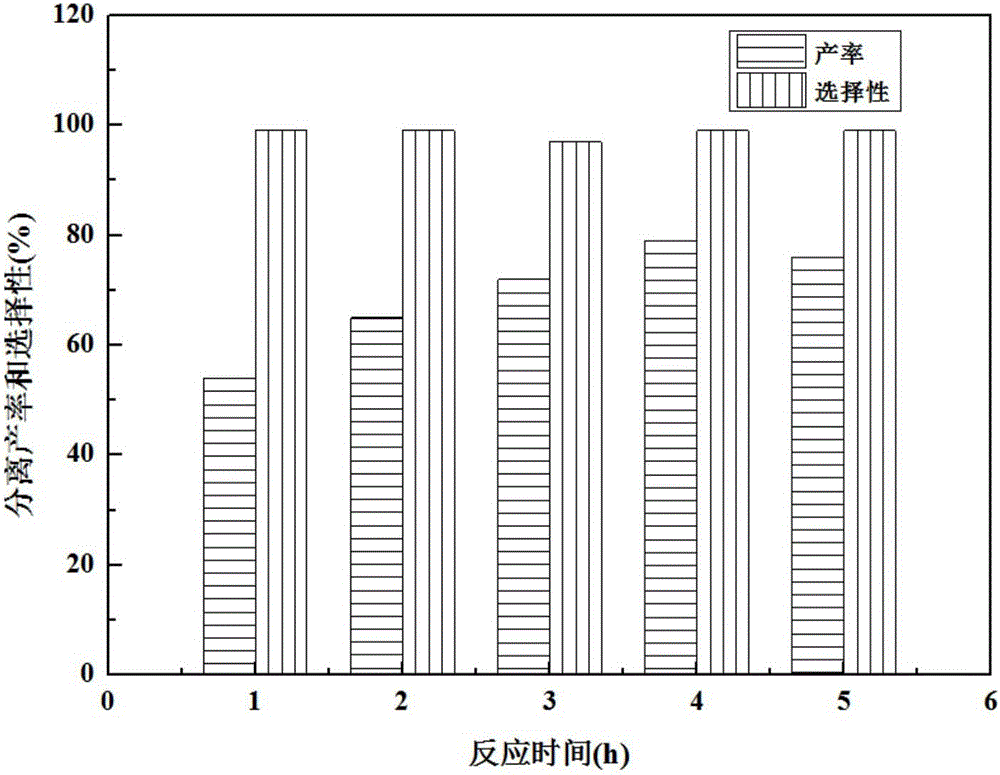

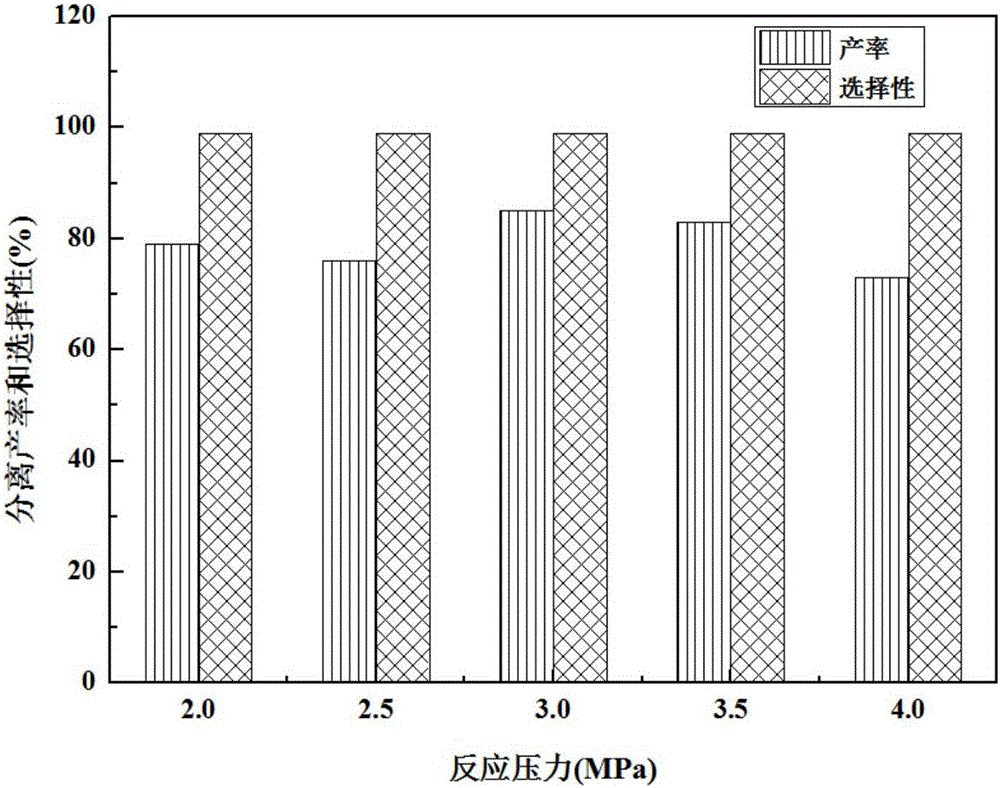

[0026] (2) Catalytic reaction: fix the polytetrafluoroethylene substrate with the blend in the reactor, feed carbon dioxide gas to discharge the air in the reactor, continue to feed carbon dioxide to make the pressure inside the reactor reach 3MPa; adjust the temperature To 120°C, react for 4h.

[0027] (3) Post-treatment of the reaction: cool the reacted reactor to room temperature, add a certain amount of ethyl acetate to extract the product after the reaction, and rotary steam; utilize the developing agent prepared by petroleum ether and ethyl acetate (1:1~ 5:1) to separate by column chromatography to obtain propylene carbonate.

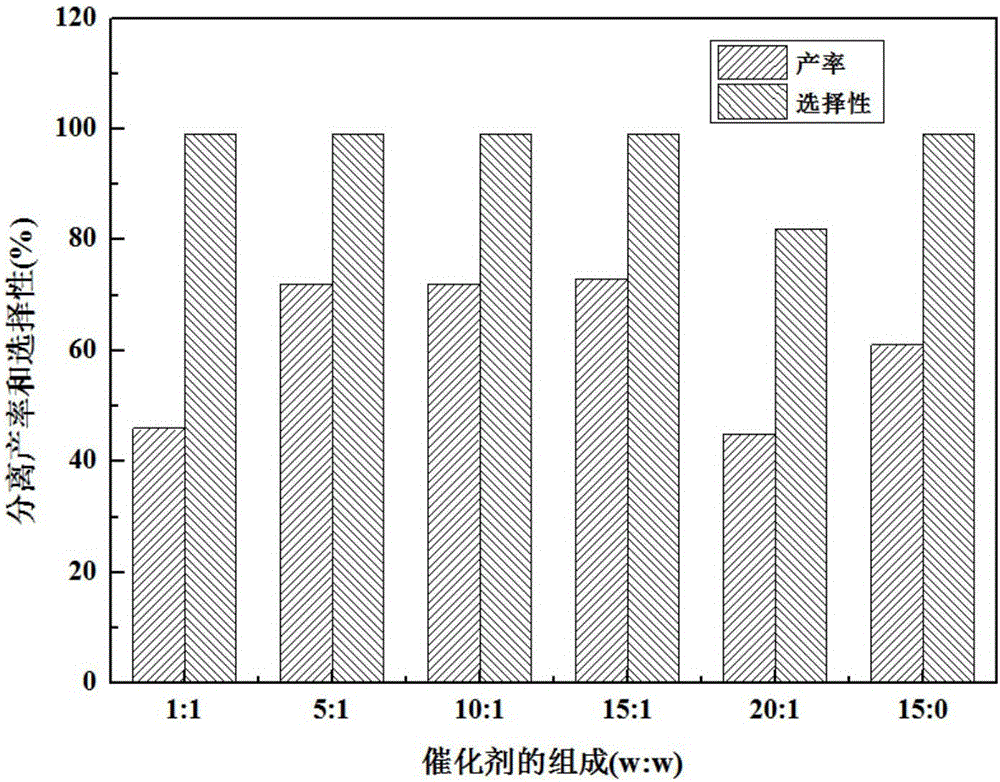

[0028] By adjusting the above-mentioned catalyst composition DBU: the mass ra...

Embodiment 2

[0030] (1) Preparation of the blend: Add 0.075g of hemicellulose, 2mL of dichloromethane, 5mL of epibromohydrin, and organic base 1,8-diazabicyclodeca into a 25mL polytetrafluoroethylene substrate Des-7-ene (DBU) 0.368mL; Stir well.

[0031] (2) Catalytic reaction: fix the polytetrafluoroethylene substrate with the blend in the reactor, feed carbon dioxide gas to discharge the air in the reactor, continue to feed carbon dioxide to make the pressure inside the reactor reach 3MPa; adjust the temperature To 120°C, react for 4h.

[0032] (3) post-processing of the reaction: the reaction kettle after the reaction is cooled to room temperature, a certain amount of ethyl acetate is added to extract the product after the reaction, rotary evaporation, and column chromatography separation to obtain the product

Embodiment 3

[0034] (1) Preparation of the blend: Add 0.075g of hemicellulose, 2mL of dichloromethane, 5mL of methyl propylene oxide, and organic base 1,8-diazabicyclo to a 25mL polytetrafluoroethylene substrate Undec-7-ene (DBU) 0.368mL; Stir well.

[0035] (2) Catalytic reaction: fix the polytetrafluoroethylene substrate with the blend in the reactor, feed carbon dioxide gas to discharge the air in the reactor, continue to feed carbon dioxide to make the pressure inside the reactor reach 3MPa; adjust the temperature To 120°C, react for 4h.

[0036] (3) post-processing of the reaction: the reaction kettle after the reaction is cooled to room temperature, a certain amount of ethyl acetate is added to extract the product after the reaction, rotary evaporation, and column chromatography separation to obtain the product

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com