Anti-radiation loess composite non-woven fabric for threading and preparation method thereof

A radiation protection, non-woven technology, applied in chemical instruments and methods, textiles and papermaking, synthetic resin layered products, etc., can solve problems such as allergies and dry skin, achieve soft texture, excellent water absorption, and promote blood circulation. and metabolic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment

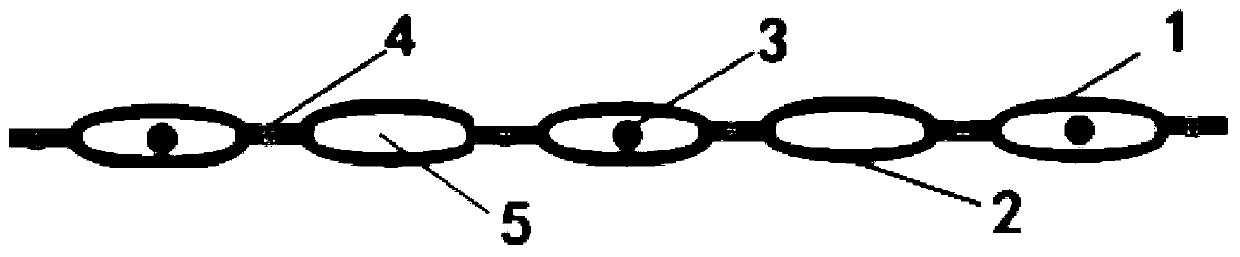

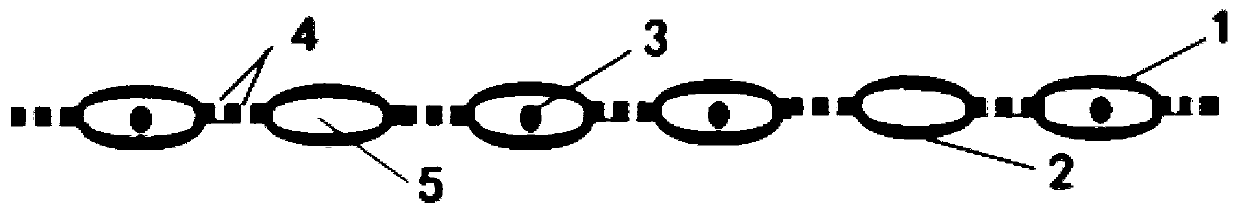

[0035] The base fabric B of the face fabric 1 provided in the embodiment of the present invention is a polyester needle-punched non-woven fabric, and the base fabric 2 is a hot-rolled needle-punched non-woven fabric;

[0036] Preparation steps include:

[0037] Preparation of face cloth 1

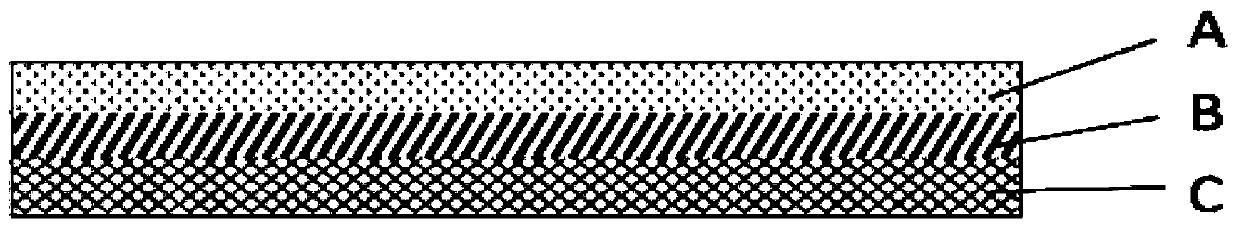

[0038] S01: Preparation of base fabric B: Feed 50-60% of polyester fibers of 1.67dtexX51mm and 40-50% of polyester fibers of 6.67dtexX51mm into the opening machine. Laying machine lays up a fiber net composed of single nets, which is needled and consolidated by up and down reciprocating needle punching machine to obtain polyester needle punched non-woven base fabric.

[0039] S02: Preparation of anti-radiation layer A: the surface of base cloth B obtained in step S01 is coated with anti-radiation slurry by means of foam coating, and coating layer C is formed on the surface of base cloth B after drying. The anti-radiation slurry is formed by mixing 10-12% of conductive carbon powder, 8-10%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com