Urea dilute urine solution treatment device and method

A solution processing and urea technology, applied in climate sustainability, ammonia preparation/separation, sustainable manufacturing/processing, etc., can solve problems such as aggravating production costs and environmental protection pressures, wasting steam condensate, and slowing decomposition. , to reduce the environmental pressure of enterprises, reduce production costs, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

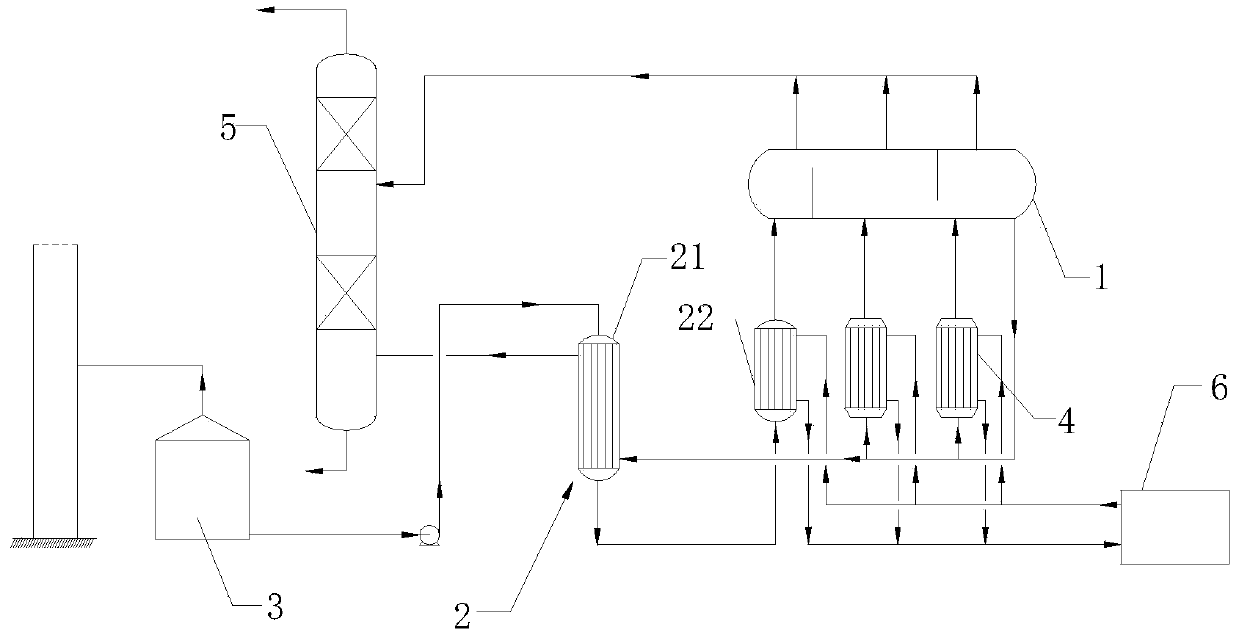

Image

Examples

Embodiment 1

[0041] Taking the urea plant with an annual output of 300,000 tons as an example, the amount of dilute urine solution processed by the hydrolyzer is 25t / h, and the medium-pressure steam consumed by the hydrolyzer is about 2t / h. The technical effects obtained by the present invention compared with those before the improvement are shown in the following table:

[0042]

[0043] 1. Economic benefit accounting:

[0044] The hydrolyzer processes 25 tons of dilute urine solution per hour, corresponding to the consumption of 2t / h of medium-pressure steam, the condensate produced by each ton of medium-pressure steam is calculated at 10 yuan, and the effective production time of the year is calculated as 300 days.

[0045]2. Annual discharge of steam condensate value:

[0046] 2t / h×24h / d×300d / y×10 yuan / t=144,000 yuan / year

[0047] 3. The annual discharge contains NH 3 About 5PPm steam condensate:

[0048] 2t / h×24h / d×300d / y=14400m 3 / y

[0049] Emission containing NH 3 The long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com