Assembly type prefabricated combined stair component

A prefabricated and staircase technology, which is applied in the direction of stairs, buildings, building structures, etc., can solve the problems of high technical level requirements for construction personnel, difficulties in hoisting and transportation, and heavy weight of prefabricated stairs, so as to save material consumption, facilitate hoisting and transportation, Produces effects with high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

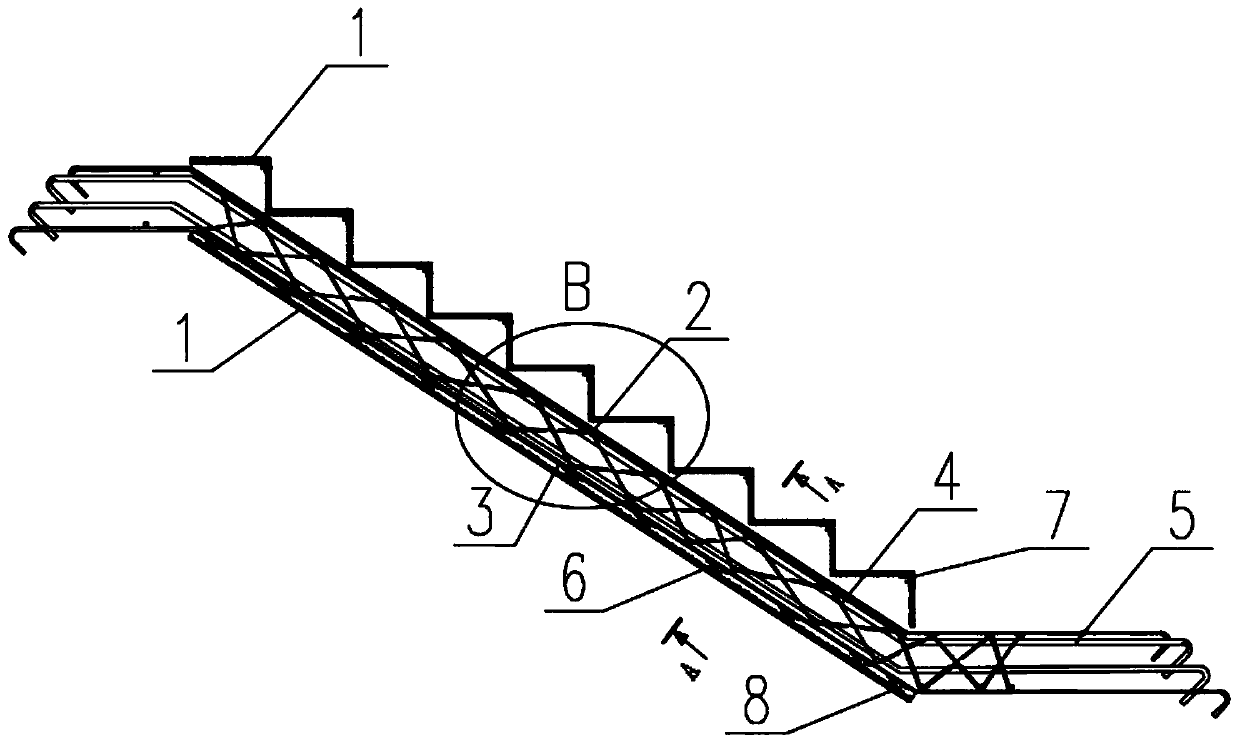

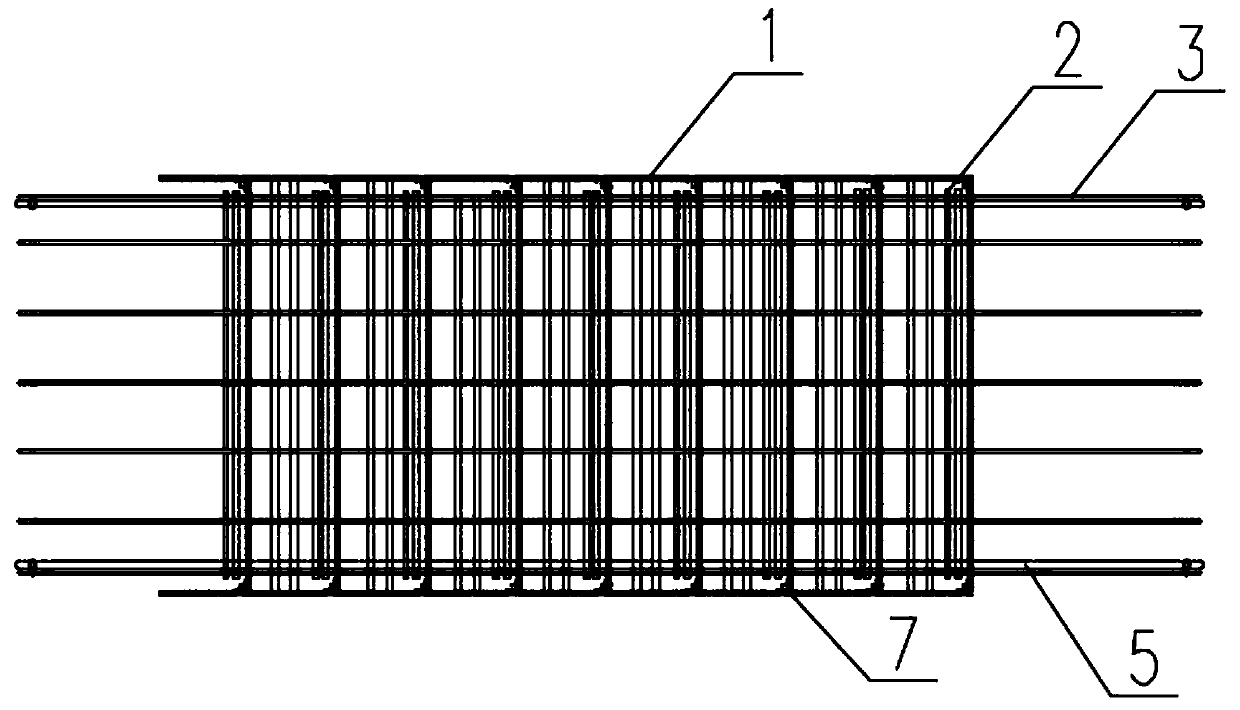

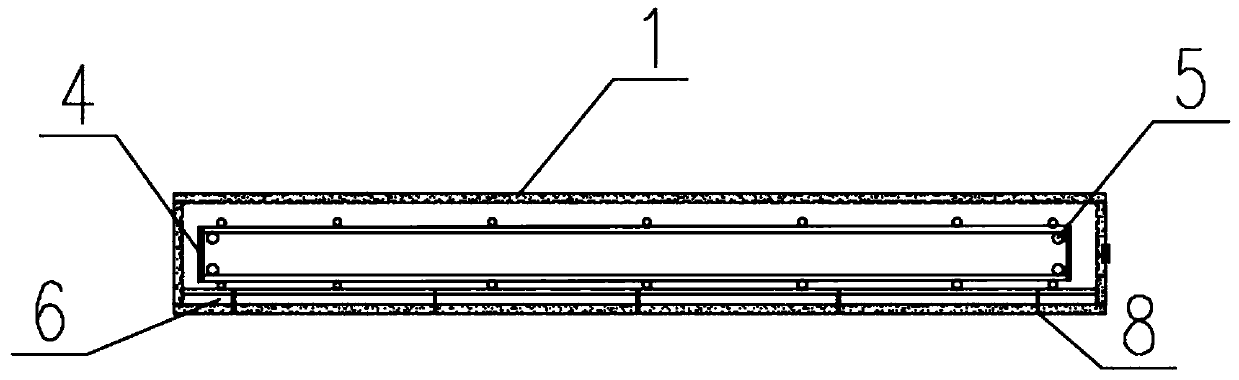

[0019] Such as Figure 1-4 As shown, an assembled prefabricated composite staircase component includes a high-precision non-dismantling formwork 1, a combined formed steel bar product, several-shaped steel 6, L-shaped steel 7 and connecting screws 8, and the two sets of high-precision non-dismantling formwork 1 are located at the On both sides of the upper and lower sides of the composite formed steel bar product, the high-precision dismantling-free formwork 1 located below is placed on a plane and inclined, and the several-shaped steel 6 is connected to the rough surface of the high-precision dismantling-free formwork 1 below through the The screws 8 are fixed, and the opening side of the several-shaped steel 6 is connected with the bottom of the composite formed steel bar product; the high-precision non-disassembly formwork 1 located above is overlapped in pairs to form stair steps, and any two adjacent The inner side of the corner of the high-precision dismantling-free form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com