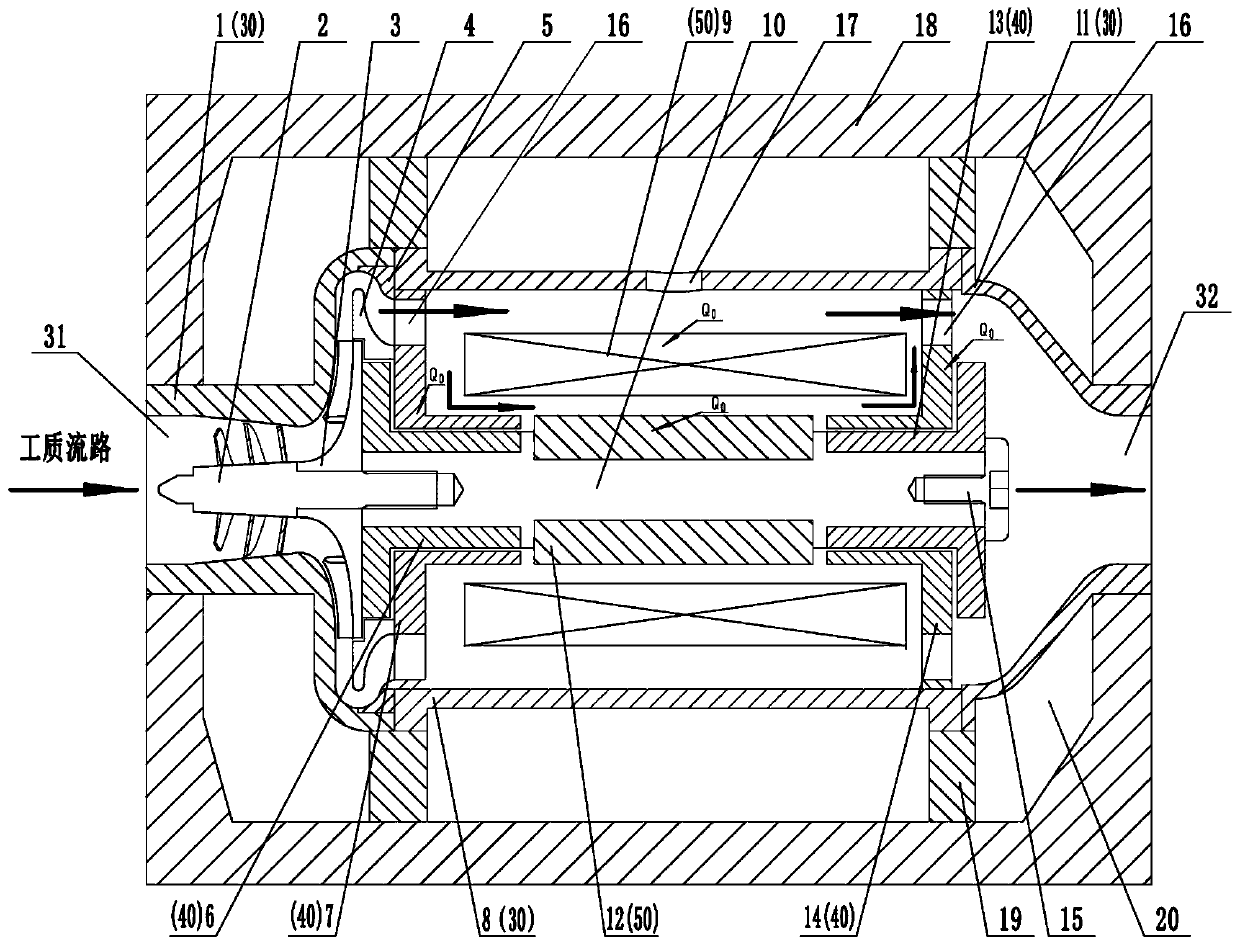

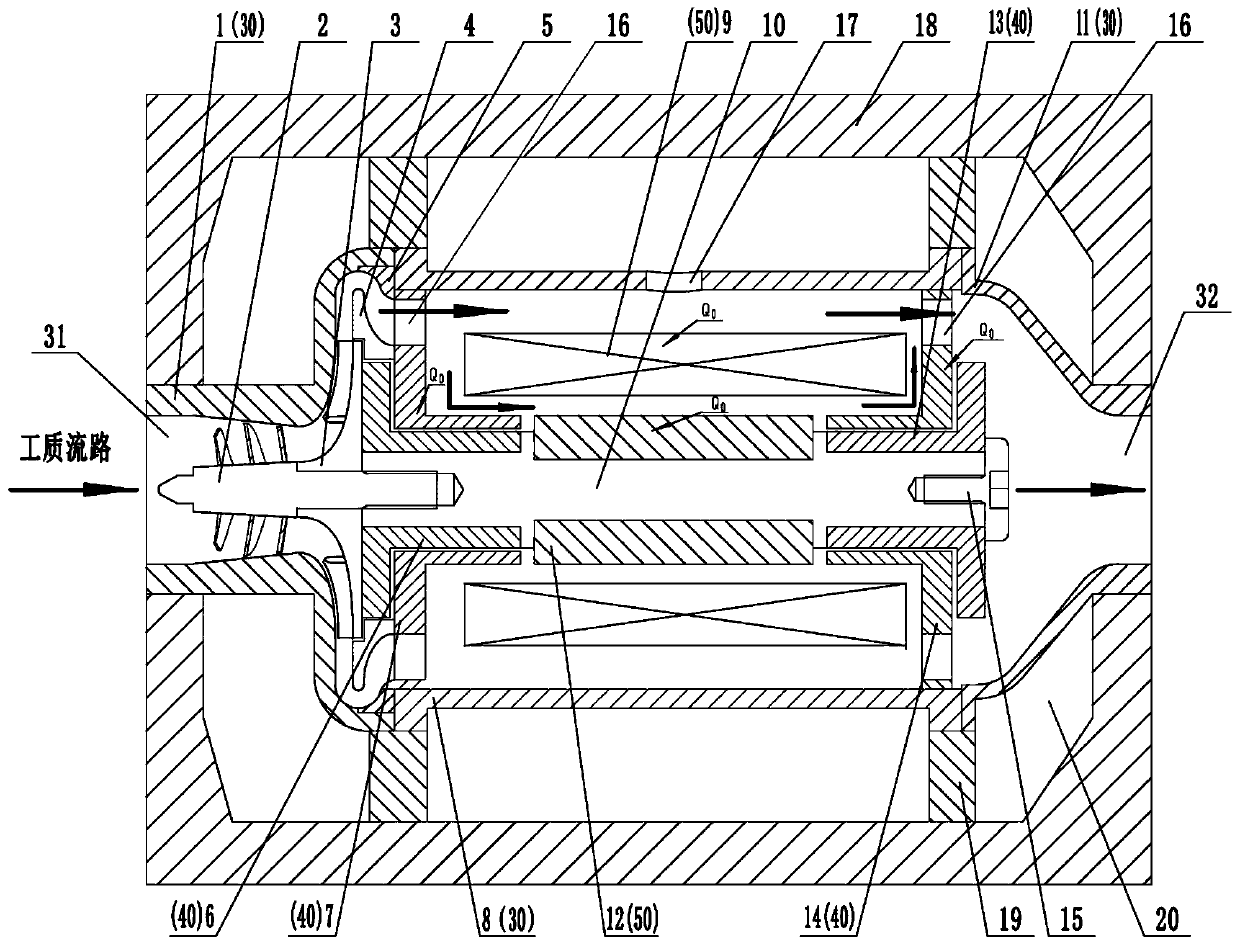

Self-vacuum heat insulation pump used for conveying low-temperature liquid

A low-temperature liquid and vacuum insulation technology, which is applied to parts of pumping devices for elastic fluids, pumps for special fluids, liquid fuel engines, etc., can solve problems such as reducing bearing reliability, bearing heating, and cooling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

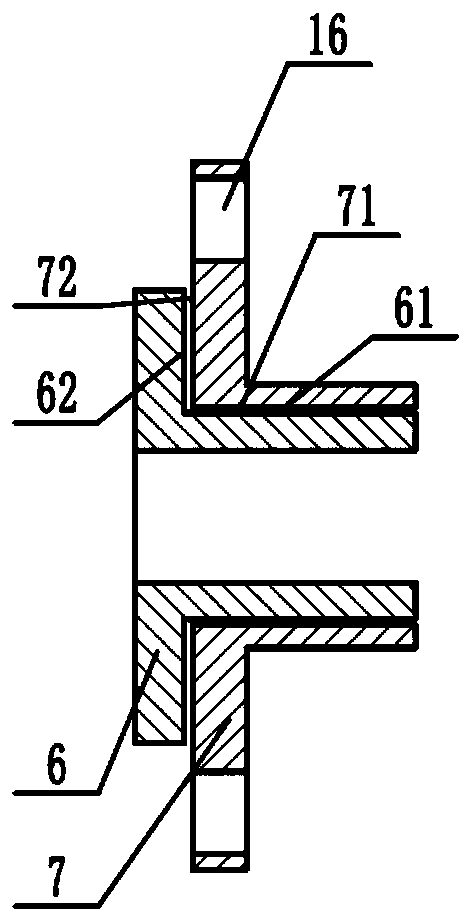

Method used

Image

Examples

Embodiment Construction

[0018] With the rapid development of cryogenic technology in recent years, many different applications of cryogenic liquids such as liquid hydrogen and liquid helium have emerged. For example, hydrogen energy is a zero-carbon, green and clean secondary energy source. It has the advantages of high combustion value, clean and pollution-free, multiple utilization forms, and storability. It is widely used in transportation, distributed energy, military power, aerospace, and large scientific projects. and other fields are regarded as the ultimate energy source in the 21st century. The industrial chain of comprehensive utilization of hydrogen energy mainly includes hydrogen production, hydrogen storage, hydrogen transportation and hydrogen utilization. The storage and transportation methods of hydrogen mainly include: high-pressure gaseous state, low-temperature liquid state and solid state, among which the two most common methods are high-pressure gaseous state and low-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com