Anion exchange resin-containing tablets

A technology of exchange resin and anion, which is applied in the field of cholesterol inhibitors, preparation of said tablets and coated tablets, and high-stability coated tablets, which can solve the problems of large number of tablets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Mixing steps:

[0054] The components were mixed using the following mixing apparatus.

[0055] Mixing device: V-type mixer, FMV100 (POWREX).

[0056] (1-1) Mixing method:

[0057] As the mixture formulation mentioned below, 1000 grams of crystalline cellulose and 50 grams of light silicic anhydride were weighed, put into a mixer and mixed therein for 5 minutes.

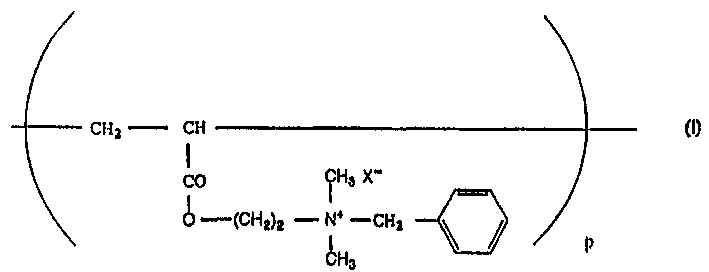

[0058] Poly(acryloyloxyethyl-N, N-dimethyl-N-benzyl ammonium chloride) with an average degree of polymerization of 12000 (as shown in general formula (I), wherein X is a chloride ion, the compound Hereinafter referred to as "Compound 1") was divided into 4 portions and each portion was added to the mixture separately with 5 minutes between additions of one portion and another portion was added with continuous mixing.

[0059] Next, weigh 50 grams of magnesium stearate, add it to the mixture, and continue mixing for 1 minute.

[0060] (1-2) Mixture formula (10 kg)

[0061] Compound 1 8900 g

[006...

Embodiment 2

[0086] (1) Mixing steps:

[0087] The components were mixed using the following mixing apparatus.

[0088] Mixing device: V-type mixer, FMV100 (POWREX).

[0089] (1-1) Mixing method:

[0090] As the mixture formulation mentioned below, 2000 grams of crystalline cellulose and 50 grams of light silicic anhydride were weighed, put into a mixer and mixed therein for 5 minutes.

[0091] Compound 1 was divided into 4 portions and each portion was added to the mixture separately with continuous mixing, with 5 minutes between the addition of one portion and the addition of the other portion.

[0092] Next, weigh 50 grams of magnesium stearate, add it to the mixture, and continue mixing for 1 minute.

[0093] (1-2) Mixture formula (10 kg)

[0094] Compound 1 7900 g

[0095] Crystalline cellulose 1000g

[0096] (The market name is Avicel PH-310 (average particle size is 40 microns)

[0098] Light Silicic Acid 50g

[0099] ...

Embodiment 3

[0103] (1) Mixing steps:

[0104] The components were mixed using the following mixing apparatus.

[0105] Mixing device: V-type mixer, FMV100 (POWREX).

[0106] (1-1) Mixing method:

[0107] For the mixture formulation mentioned below, 1000 grams of crystalline cellulose, 550 grams of lactose and 50 grams of light silicic anhydride were weighed, put into a mixer and mixed therein for 5 minutes.

[0108] Compound 1 was divided into 4 portions and each portion was added to the mixture separately with continuous mixing, with 5 minutes between the addition of one portion and the addition of the other portion.

[0109] Next, weigh 50 grams of magnesium stearate, add it to the mixture, and continue mixing for 1 minute.

[0110] (1-2) Mixture formula (10 kg)

[0111] Compound 1 8350 g

[0112] Crystalline cellulose 1000g

[0113] (The market name is Avicel PH-F20 (average particle size is 17 microns)

[0114] Lactose 550g

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent specific gravity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Apparent specific gravity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com