Manufacturing process of wear-resistant cosmetic packaging bottles

A production process and bottle packaging technology, applied in household components, household appliances, other household appliances, etc., can solve problems such as discoloration of the bottle body, and achieve the effect of helping preservation, enhancing wear resistance, and stable appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

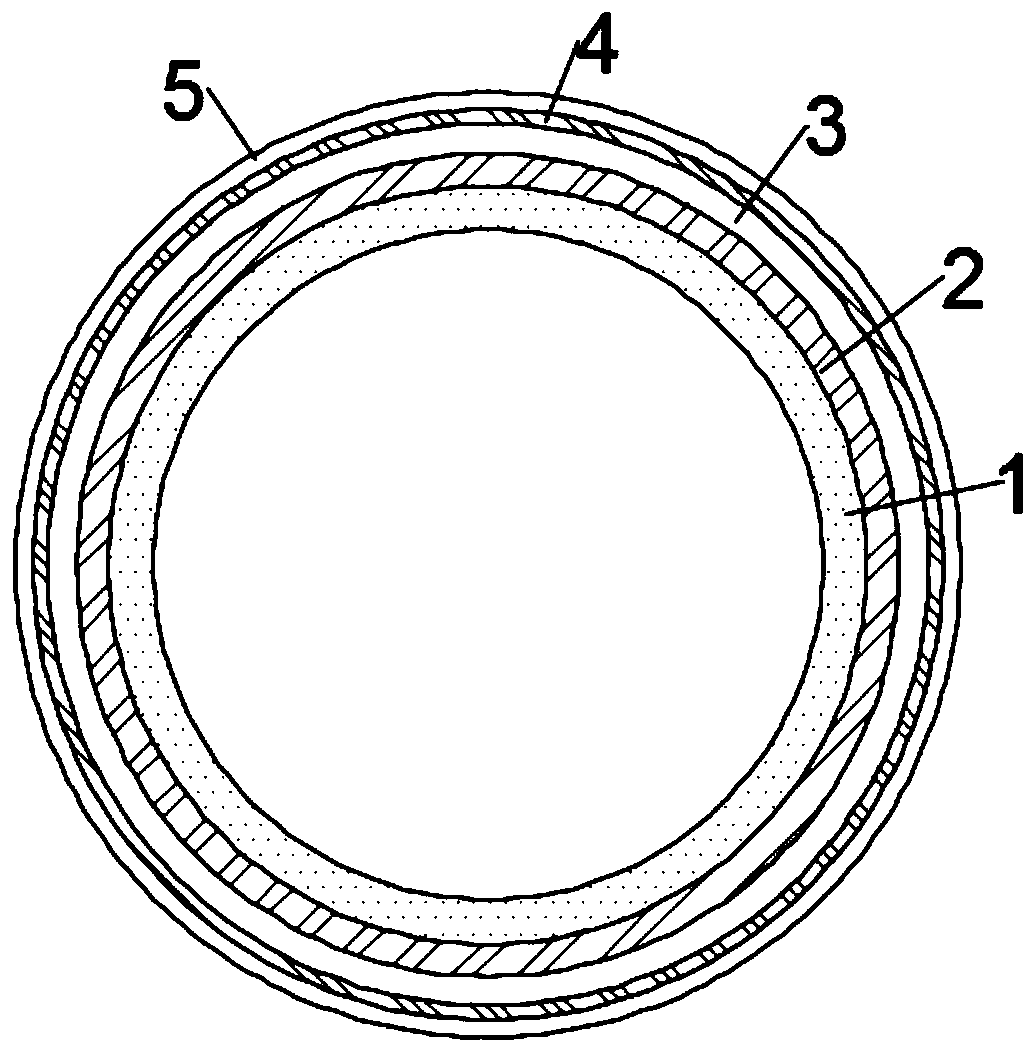

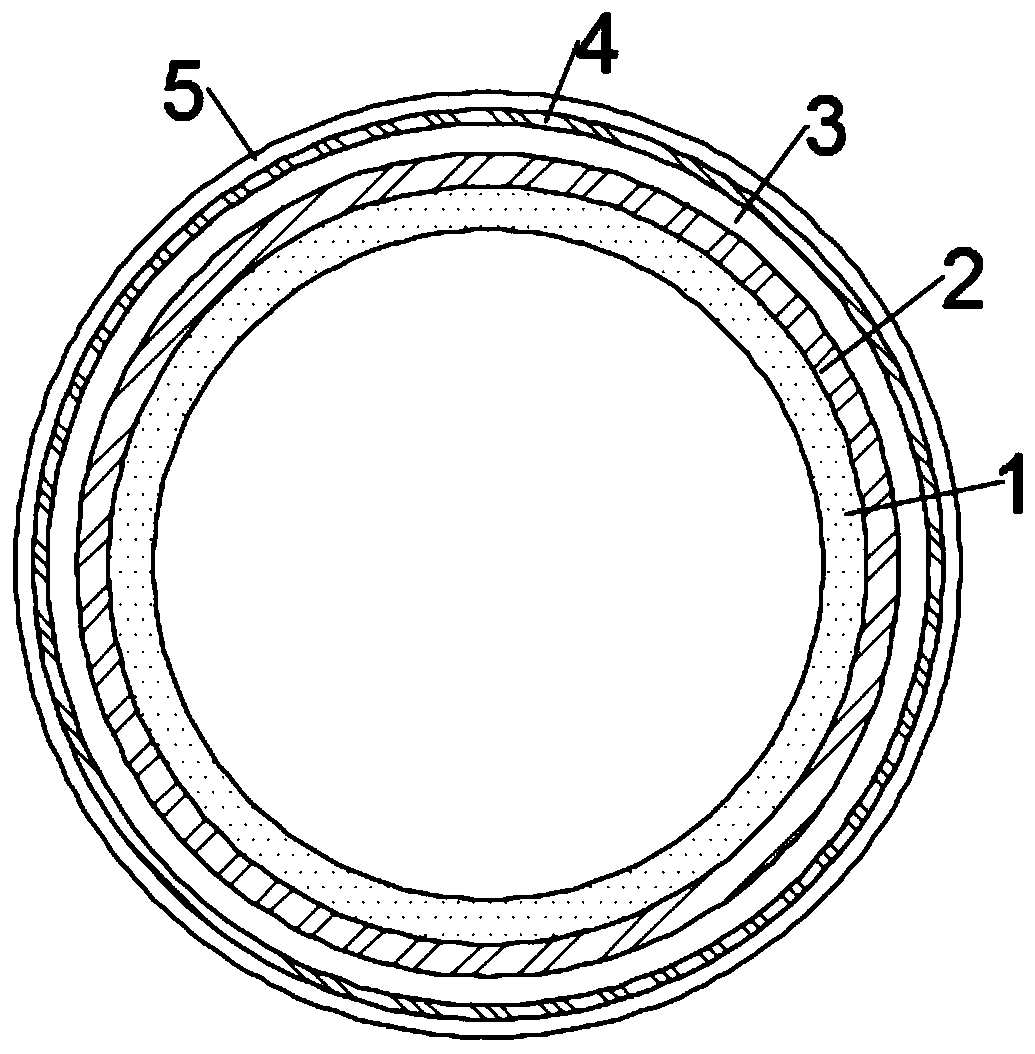

Image

Examples

Embodiment 1

[0017] A manufacturing process of a wear-resistant cosmetic packaging bottle, the steps are as follows:

[0018] S1. Weigh the PET granules, then put the PET granules into a dryer, and dry the PET granules at 70° C. for 2 hours. After drying, grind the PET granules to obtain PET granule powder;

[0019] S2, then weigh polystyrene and hyaluronic acid, put the mixture into a magnetic stirrer after pulverization, stir and mix for 10 minutes, then add methanol to the mixture, and continue stirring for 10 minutes to obtain mixed component A;

[0020] S3, put the powder of PET particles into the mixed component A to obtain the mixed component B, then filter, get the filter residue, then rinse the filter residue with acetone for 3 times, and then rinse the filter residue with deionized water after washing, the number of times of washing is 2 times, dry the mixed component B, and then process the mixed component B through screw melt extrusion. After processing, put nano-titanium oxide...

Embodiment 2

[0024] A manufacturing process of a wear-resistant cosmetic packaging bottle, the steps are as follows:

[0025] S1. Weigh the PET granules, then put the PET granules into a dryer, and dry the PET granules at 80° C. for 3 hours. After the drying, grind the PET granules to obtain the powder of the PET granules;

[0026] S2, then weigh polystyrene and hyaluronic acid, put the mixture into a magnetic stirrer after pulverization, stir and mix for 20 minutes, then add methanol to the mixture, and continue stirring for 30 minutes to obtain a mixed component A;

[0027] S3, put the powder of PET particles into the mixed component A to obtain the mixed component B, then filter, get the filter residue, then rinse the filter residue with acetone for 5 times, and then rinse the filter residue with deionized water after washing, the number of times of washing is 4 times, dry the mixed component B, and then process the mixed component B through screw melt extrusion. After the processing is...

Embodiment 3

[0031] A manufacturing process of a wear-resistant cosmetic packaging bottle, the steps are as follows:

[0032] S1. Weigh the PET granules, then put the PET granules into the dryer, and dry the PET granules at 72°C for 2.2 hours. After drying, grind them to obtain the powder of PET granules. ;

[0033] S2. Then weigh polystyrene and hyaluronic acid, pulverize and put the mixture into a magnetic stirrer, stir and mix for 11 minutes, then add methanol to the mixture, and continue stirring for 13 minutes to obtain mixed component A;

[0034] S3, put the powder of PET particles into the mixed component A to obtain the mixed component B, then filter, get the filter residue, then rinse the filter residue with acetone for 3 times, and then rinse the filter residue with deionized water after washing, the number of times of washing is 2 times, dry the mixed component B, and then process the mixed component B through screw melt extrusion. After processing, put nano-titanium oxide into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com