High-Mooney natural rubber foamed rubber compound and preparation method thereof

A technology of natural rubber and mixed rubber, which is applied in the field of natural rubber foaming. It can solve the problems of unsuitable continuous production, unstable foamed products, and low Mooney viscosity of raw rubber, and achieve optimal vulcanization speed, good elasticity, and optimized The effect of foaming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

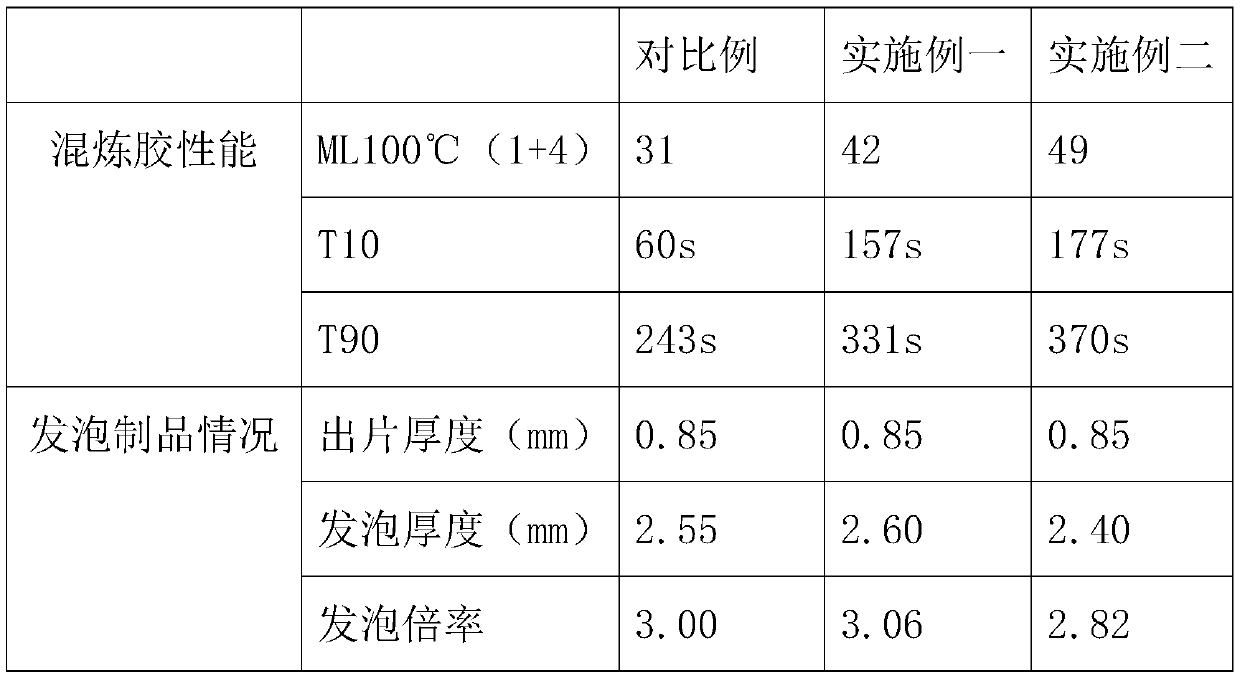

Examples

specific Embodiment 1

[0035] A high Mooney natural rubber foaming rubber compound, in parts by weight, the rubber compound comprises: 100 parts of natural rubber, 10 parts of active agent, 1.5 parts of anti-aging agent, 30 parts of softening agent, 3.5 parts of vulcanizing agent, 3.5 parts of accelerator, 2 parts of dispersant, 215 parts of filler, 5 parts of foaming agent H (foaming agent H: dinitrosopentamethylenetetramine), 2 parts of foaming aid BK;

[0036] The preparation method of this high Mooney natural rubber foaming compound comprises the following steps:

[0037] Step 1, ingredients: 100 parts of natural rubber, 10 parts of active agent, 1.5 parts of anti-aging agent, 30 parts of softening agent, 3.5 parts of vulcanizing agent, 3.5 parts of accelerator, 2 parts of dispersant, 215 parts of filler, foaming agent H 5 2 parts, foaming aid BK 2 parts, precisely configure raw materials;

[0038] Step 2, one-stage mixing: Add filler and natural rubber to the internal mixer, the pressure of th...

specific Embodiment 2

[0042] A high Mooney natural rubber foaming rubber compound, in parts by weight, the rubber compound comprises: 100 parts of natural rubber, 10 parts of active agent, 1.5 parts of anti-aging agent, 40 parts of softening agent, 3.5 parts of vulcanizing agent, Accelerator 3.3 parts, dispersant 2 parts, filler 260 parts, foaming agent H 6 parts, foaming aid BK 2 parts.

[0043] The preparation method of this high Mooney natural rubber foaming compound comprises the following steps:

[0044] Step 1, ingredients: 100 parts of natural rubber, 10 parts of active agent, 1.5 parts of anti-aging agent, 40 parts of softening agent, 3.5 parts of vulcanizing agent, 3.3 parts of accelerator, 2 parts of dispersant, 260 parts of filler, foaming agent H 6 2 parts, foaming aid BK 2 parts, precisely configure raw materials;

[0045] Step 2, one-stage mixing: Add filler and natural rubber to the internal mixer, the pressure of the top bolt is 60bar, the speed is 45r / min, the temperature of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com