Polyurethane foaming material and preparation method thereof

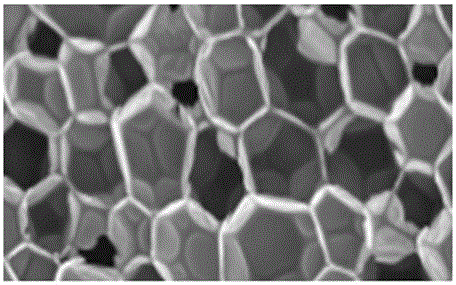

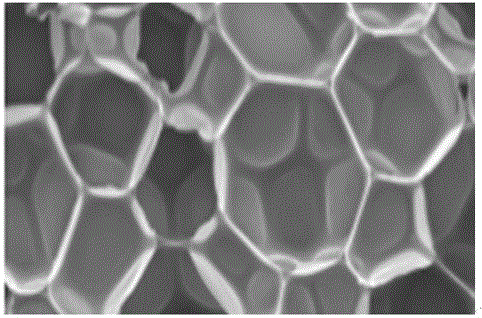

A foaming material and polyurethane technology, applied in the field of foaming materials, can solve the problems of large foaming pore size and uneven distribution of foaming pore size, and achieve the effects of uniform distribution of cells, small size, and improved thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention also provides the preparation method of polyurethane foam material, and described method comprises the steps:

[0022] (1) Add the combined polyether into the high and low pressure circulation system, and a nucleating agent adding device is provided at the filter outlet of the combined polyether pipeline. When the combined polyether passes through the filter and is about to enter the mixing tank, open the The nucleating agent adding device, the nucleating agent is mixed into the combination polyether, and then the nucleating agent and the combination polyether are added into the mixing tank;

[0023] The pressure of the combined polyether fluid at the filter outlet of the combined polyether pipeline is relatively high, which can quickly mix the nucleating agent into the combined polyether, and can fully and uniformly dissolve the nucleating agent in the combined polyether, thereby making it possible to Combining polyether to form a large number of ...

Embodiment 1

[0032] (1) Add the combined polyether into the high and low pressure circulation system, and a nucleating agent adding device is provided at the filter outlet of the combined polyether pipeline. When the combined polyether passes through the filter and is about to enter the mixing tank, open the Nucleating agent adding device, mix the nucleating agent carbon dioxide into the combination polyether, and then add the carbon dioxide and the combination polyether into the mixing tank; the pressure of the high and low pressure circulation system is 12MPa, and the temperature is 18°C;

[0033] (2) foaming agent cyclopentane and isopentane are added in the mixing tank and mixed with the combination polyether, and then the mixed cyclopentane, isopentane and the combination polyether are added in the buffer tank;

[0034] (3) Keeping the pressure of the buffer tank is 13Mpa, adding isocyanate in the black material tank, keeping the pressure of the black material tank is 12Mpa, and the pr...

Embodiment 2

[0038] (1) Add the combined polyether into the high and low pressure circulation system, and a nucleating agent adding device is provided at the filter outlet of the combined polyether pipeline. When the combined polyether passes through the filter and is about to enter the mixing tank, open the Nucleating agent adding device, mix the nucleating agent nitrogen into the combined polyether, and then add the nitrogen and combined polyether into the mixing tank; the pressure of the high and low pressure circulation system is 13MPa, and the temperature is 20°C;

[0039] (2) foaming agent cyclopentane and isopentane are added in the mixing tank and mixed with the combination polyether, and then the mixed cyclopentane, isopentane and the combination polyether are added in the buffer tank;

[0040] (3) keep the pressure of buffer tank to be 13Mpa, isocyanate is joined in the black material tank, keep the pressure of black material tank to be 14Mpa, the pressure difference of buffer tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com