Non-slip heat aging resistant EVA and NR composite foaming material and preparation method thereof

A technology of composite foaming and heat aging resistance, which is applied in the field of polymer composite foam materials, can solve problems such as product failure, and achieve the effects of improved skid resistance and heat aging resistance, good mechanical properties, and low specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing anti-slip and heat-resistant aging EVA, NR composite foaming material, the specific steps are:

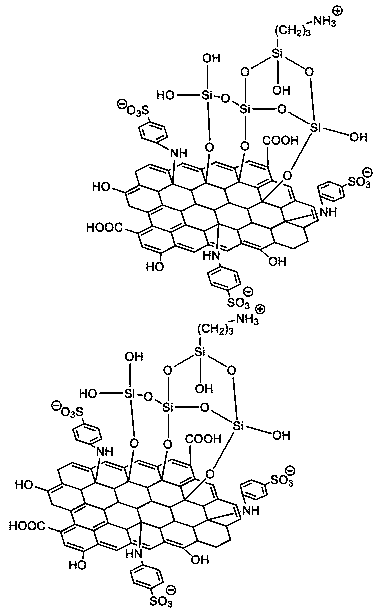

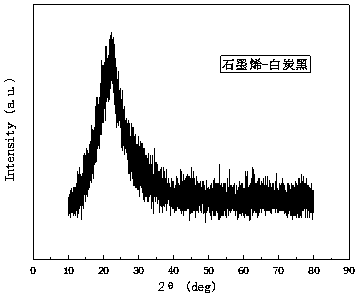

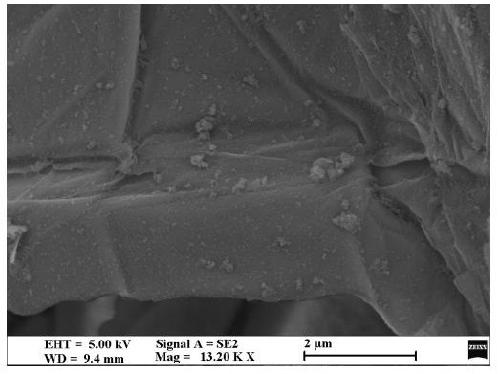

[0027] 1) Preparation of graphene oxide template: Dissolve 1 g of flake graphite in 23 mL of concentrated sulfuric acid, place it in a magnetic stirrer for stirring, and slowly add 3 g of potassium permanganate and 1 g of sodium nitrate after it is uniformly dispersed. Add within 1 hour; after another 2 hours of reaction, start to heat up to 98°C, when the solution system becomes thick, add 44ml deionized water and 5ml 5wt% hydrogen peroxide solution dropwise, and titrate with 5wt% hydrochloric acid until the solution is not Regeneration of bubbles means the end of the reaction; wash the prepared graphene oxide with deionized water, centrifuge, freeze-dry and add 200 mg of prepared graphene oxide into the flask, add deionized water for ultrasonication, and stir; 10 ml of absolute ethanol Put it into a flask, add 400 mg of sodium p-aminobenzenesulfonate...

Embodiment 2

[0033] A method for preparing anti-slip and heat-resistant aging EVA, NR composite foaming material, the specific steps are:

[0034] 1) Preparation of graphene oxide template: Dissolve 1 g of flake graphite in 23 mL of concentrated sulfuric acid, place it in a magnetic stirrer for stirring, and slowly add 3 g of potassium permanganate and 1 g of sodium nitrate after it is uniformly dispersed. Add within 1 hour; after another 2 hours of reaction, start to heat up to 98°C, when the solution system becomes thick, add 44ml deionized water and 5ml 5wt% hydrogen peroxide solution dropwise, and titrate with 5wt% hydrochloric acid until the solution is not Regeneration of bubbles means the end of the reaction; wash the prepared graphene oxide with deionized water, centrifuge, freeze-dry and add 200 mg of prepared graphene oxide into the flask, add deionized water for ultrasonication, and stir; 10 ml of absolute ethanol Put it into a flask, add 400 mg of sodium p-aminobenzenesulfonate...

Embodiment 3

[0040] A method for preparing anti-slip and heat-resistant aging EVA, NR composite foaming material, the specific steps are:

[0041] 1) Preparation of graphene oxide template: Dissolve 1 g of flake graphite in 23 mL of concentrated sulfuric acid, place it in a magnetic stirrer for stirring, and slowly add 3 g of potassium permanganate and 1 g of sodium nitrate after it is uniformly dispersed. Add within 1 hour; after another 2 hours of reaction, start to heat up to 98°C, when the solution system becomes thick, add 44ml of deionized water and 5ml of 5% hydrogen peroxide solution dropwise, and titrate with 5% hydrochloric acid until the solution is not Regeneration of bubbles means the end of the reaction; wash the prepared graphene oxide with deionized water, centrifuge, freeze-dry and add 200 mg of prepared graphene oxide into the flask, add deionized water for ultrasonication, and stir; 10 ml of absolute ethanol Put it into a flask, add 400 mg of sodium p-aminobenzenesulfona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com