Energy-saving supercritical EPE foam molding process

A foam molding, supercritical technology, applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of reducing product quality, uneven density, molding difficulties, etc., to ensure the discharge efficiency, The effect of uniform density and uniform foam pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

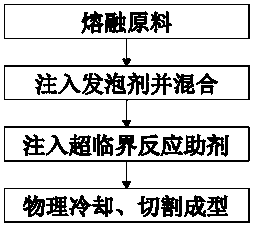

Image

Examples

Embodiment

[0031] The foam plastic raw material matrix is a polystyrene resin matrix;

[0032] The reinforcement material is a mixture of glass fiber and aluminum silicate fiber;

[0033] The supercritical reaction additive is supercritical CO 2 reaction aids;

[0034] The components of the foam plastic raw material matrix, reinforcing material, coloring masterbatch and reaction auxiliary agent are as follows: 70 parts of foam plastic raw material matrix, 9 parts of reinforcing material, 6.5 parts of coloring masterbatch, and 7 parts of reaction auxiliary agent;

[0035] The specific molding steps of the energy-saving supercritical EPE foam molding process are as follows:

[0036] S1: Melting raw materials: mix polystyrene resin matrix, glass fiber, aluminum silicate fiber mixture, and coloring masterbatch through a mixing equipment. An electric heating mechanism is installed inside the mixing equipment, and the heating temperature of the electric heating mechanism is 170°C;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com