Movable cover vehicle and treatment method for water-containing flying dust in steel slag hot disintegration process

A processing method and hot stuffy technology, which are applied in the field of mobile hooded car and the treatment of water-containing fugitive dust in the hot stuffy process of steel slag, can solve the problems of harsh working site environment, environmental pollution of steel structure, and reduced visibility, prevent steel slag from splashing, and meet emission requirements. , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

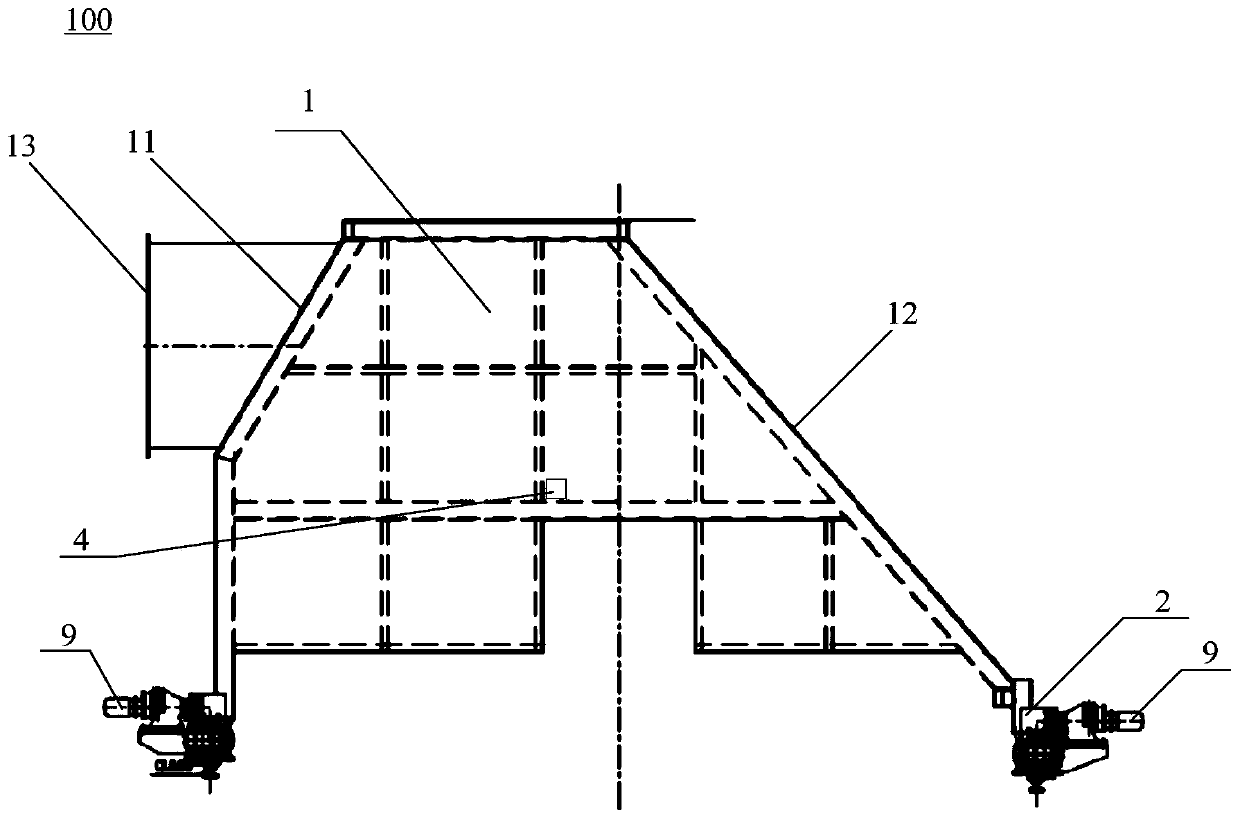

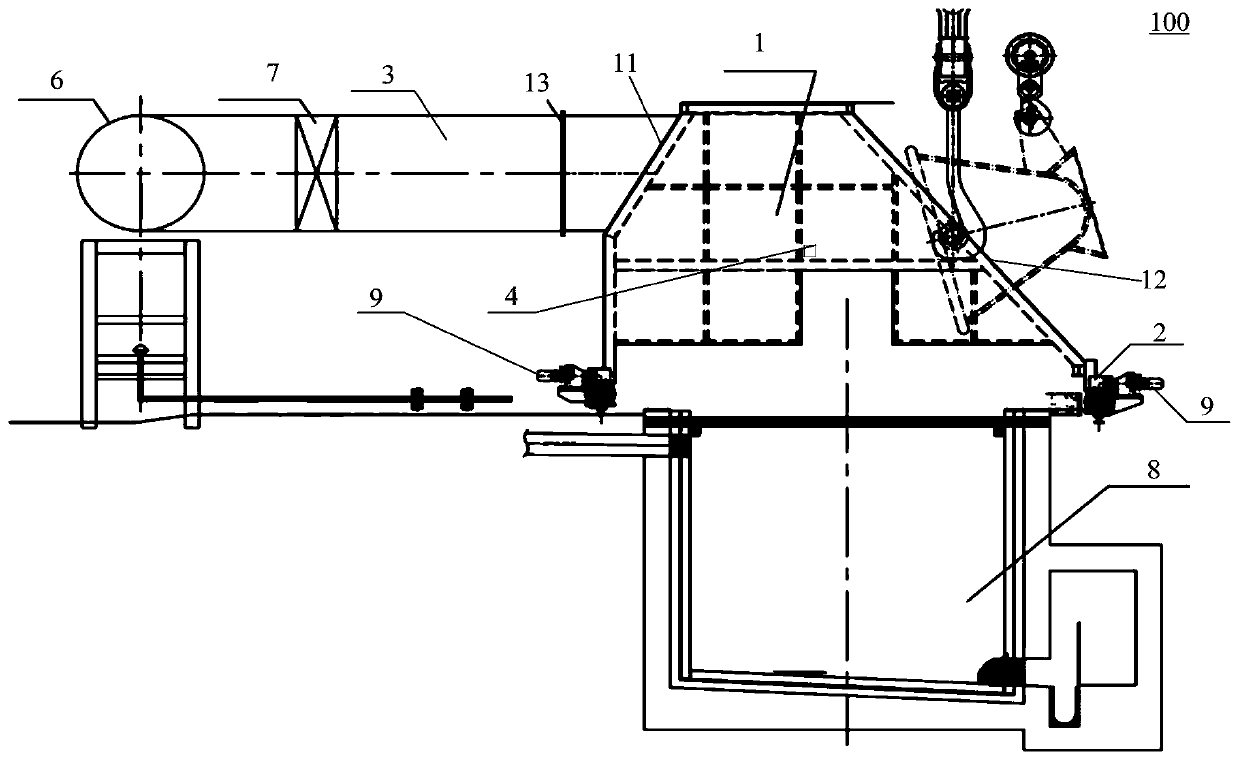

[0024] Such as figure 1 As shown, it shows a mobile cover car 100 according to the embodiment of the present invention, including a cover 1 for covering the hot stuffy pool 8 and a moving part 2 located below the cover 1, and the cover 1 is provided with a communicating mobile cover The interface part 11 between the inside and outside of the car 100 and the opening part 12 for pouring steel slag, the moving part 2 cooperates with the track on the edge of the hot stuffy pool 8, and drives the casing 1 to move on the track.

[0025] The mobile cover car 100 of this embodiment is mainly used in the steel slag heat-stuffing process, that is, pour the high-temperature steel slag (about 1600 degrees Celsius) into the hot-stuff pool 8 to spray water, cover the slag cover, The hot slag in the pool 8 meets water to generate a large amount of saturated steam, which breaks and pulverizes itself. When the mobile cover car 100 of this embodiment is in use, the moving part 2 is driven by a...

Embodiment 2

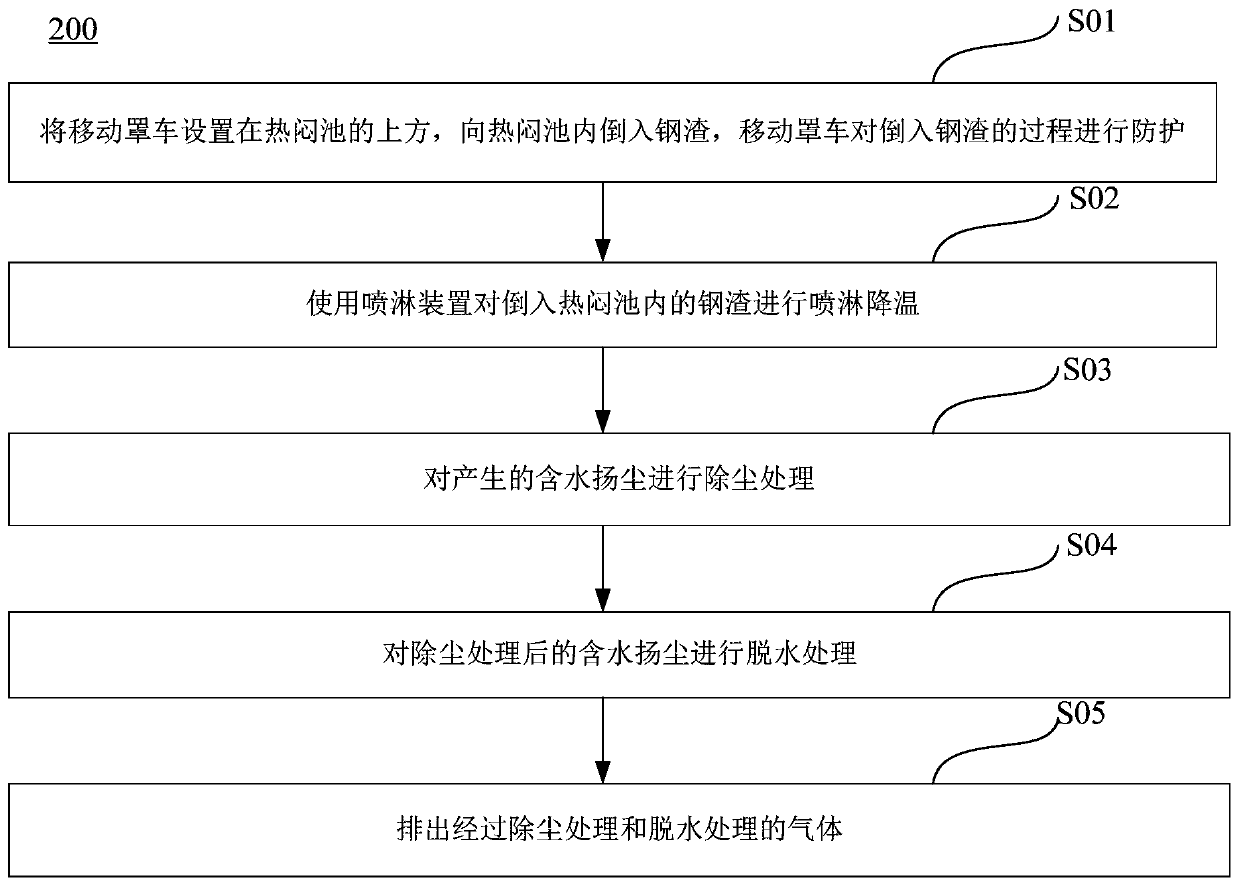

[0038] Such as image 3 Shown is a method 200 for treating water-containing dust in a steel slag heat-stuffing process according to Embodiment 2 of the present invention, comprising the following steps:

[0039] Step S01: Set the mobile cover car 100 above the hot stuffy pool 8, pour steel slag into the hot stuffy pool 8, and the mobile cover car 100 protects the process of pouring steel slag; Step S02: Use 4 pairs of spraying devices Pour the steel slag into the hot stuffy pool 8 to spray and cool down; step S03: perform dedusting treatment on the generated water-containing fugitive dust; step S04: perform dehydration treatment on the water-containing fugitive dust after dust removal treatment; step S05: discharge after dust removal treatment and dehydration treatment gas.

[0040] Because in the hot stuffy treatment process of steel slag, a large amount of steam will be generated after the high-temperature steel slag is sprayed with water, which also includes various dusts....

Embodiment 3

[0043] Such as Figure 4 As shown, according to the method 200 for treating water-containing dust in the steel slag hot stuffy process of this embodiment, in step S01, before pouring steel slag into the hot stuffy pool 8, the hot stuffy pool 8 can be firstly treated with slag pad S011, and then After pouring the steel slag into the hot stuffy pool, the steel slag in the hot stuffy pool 8 can be raked S012 by using external tools. Because the hot stuffy pool 8 is recycled, in a steel slag hot stuffy process, the steel slag in the hot stuffy pool 8 is sprayed with water and covered with a hot stuffy cover to make the steel slag and water fully react, and after the full reaction, the steel slag is removed from the hot stuffy pool If the interval between the two steel slag hot stuffing processes is short, there may still be residual moisture in the hot stuffy pool 8 from the previous steel slag hot stuffing process, making the environment in the hot stuffy pool 8 humid If the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com